• Uyini Umehluko phakathi kwe-CNC ne-Laser Cutter?

• Ingabe Kufanele Ngicabange Ukusika Ummese Womzila We-CNC?

• Ingabe kufanele ngisebenzise ama-Die-Cutters?

• Iyiphi Indlela Yokusika Engcono Kakhulu Kimi?

Ingabe uzizwa ulahlekile kancane uma kuziwa ekukhetheni umshini wokusika indwangu ophelele ngezidingo zakho zokukhiqiza? Uma utshuza nje emhlabeni wokusika i-laser yendwangu, ungase uzibuze ukuthi ingabe umshini we-laser CO2 ukufanele yini.

Namuhla, ake sikhanyise ekusikeni izindwangu nezinto eziguquguqukayo. Kubalulekile ukukhumbula ukuthi i-laser cutter ayiyona inketho engcono kakhulu kuyo yonke imboni. Kodwa uma ulinganisa ubuhle nobubi, uzothola ukuthi i-laser cutter yendwangu ingaba ithuluzi elihle kwabaningi. Ngakho-ke, ubani okufanele acabangele lobu buchwepheshe?

Ukubuka Ngokushesha >>

Thenga Umshini We-Laser Wendwangu VS CNC Knife Cutter?

Iyiphi Imboni Yezindwangu Efanele Ukusika I-Laser?

Ukunikeza umbono ojwayelekile walokho okungenziwa imishini ye-laser ye-CO2, ngifuna ukwabelana nani nonke lokho amakhasimende e-MimoWork akwenzayo ngokusebenzisa umshini wethu. Amanye amakhasimende ethu enza:

Futhi abaningi abanye abaningi. Umshini wendwangu yokusika i-laser awukhawulelwe ekusikeni izingubo nezindwangu zasekhaya. HlolaUhlolojikelele Lwezinto ezibonakalayo - MimoWorkukuze uthole izinto zokwakha ezengeziwe kanye nezicelo ofuna ukuzisika nge-laser.

Ukuqhathanisa mayelana ne-CNC ne-Laser

Kuthiwani ngabasiki bemimese? Uma kukhulunywa ngendwangu, isikhumba, nezinye izinto zokugoqa, abakhiqizi abaningi bavame ukukala umshini wokusika ummese we-CNC ngokumelene nomshini wokusika we-CO2 laser.

Kubalulekile ukuqonda ukuthi lezi zindlela ezimbili azikona nje ukuphikisa; empeleni ziyaphelelisana emhlabeni wokukhiqizwa kwezimboni.

Ezinye izinto ezisetshenziswayo zisikwa kangcono ngemibese, kuyilapho ezinye zikhanya lapho kusetshenziswa ubuchwepheshe be-laser. Yingakho ngokuvamile uzothola amathuluzi ahlukahlukene okusika ezimbonini ezinkulu. Ithuluzi ngalinye linamandla alo, okwenza kube semqoka ukukhetha elifanele lomsebenzi!

◼ Izinzuzo ze-CNC Cutting

Ukusika Izendlalelo Eziningi Zendwangu

Uma kukhulunywa ngezindwangu, enye yezinzuzo ezivelele zesisiki sommese ikhono laso lokusika izendlalelo eziningi zendwangu ngesikhathi esisodwa. Lesi sici singathuthukisa kakhulu ukusebenza kahle kokukhiqiza! Ezimbonini ezikhipha isamba esikhulu sezimpahla zokugqoka nezindwangu zasekhaya nsuku zonke—cabanga ukuthi ama-OEM amaqhawekazi emfashini asheshayo afana no-Zara kanye ne-H&M—isisiki sommese se-CNC sivame ukuba yinketho. Ngenkathi ukusika izendlalelo eziningi kungethula izinselele ezinembayo, ungakhathazeki! Eziningi zalezi zinkinga zingaxazululwa ngesikhathi sokuthunga.

Ukubhekana Nezindwangu Ezinobuthi Njenge-PVC

Kubalulekile futhi ukukhumbula ukuthi ezinye izinto azifanele ukusika i-laser. Isibonelo, ukusika i-PVC nge-laser kukhiqiza intuthu enobuthi eyaziwa ngokuthi igesi ye-chlorine. Kulezi zimo, i-CNC knife cutter iyindlela ephephile futhi ehlakaniphe kakhulu. Ukugcina ukuphepha nokusebenza kahle engqondweni kuzoqinisekisa ukuthi wenza ukukhetha okungcono kakhulu kwezidingo zakho zokukhiqiza!

◼ Izinzuzo zokusika i-Laser

Ukusika Izindwangu Ezisezingeni Eliphezulu

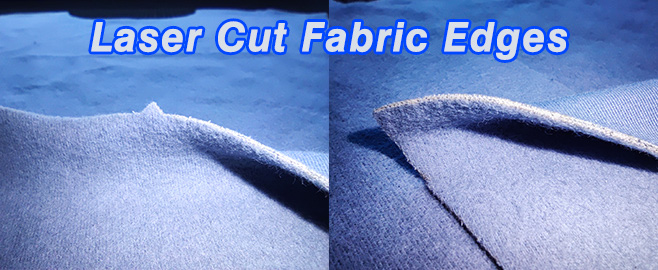

Manje, ake sikhulume ngokusika kwe-laser! Yini eyenza kube inketho ekhangayo ezindwangu? Enye yezinzuzo ezinkulu ukwelapha ukushisa okuza ne-laser cutting.

Le nqubo ivala imiphetho yezinto ezithile, ikunikeza isiphetho esihlanzekile, esibushelelezi okulula ukusiphatha. Iwusizo ikakhulukazi ezindwangu zokwenziwa ezifana ne-polyester.

Enye inzuzo yokusika i-laser yindlela yayo yokuxhumana ngaphandle kokuthinta. Njengoba i-laser ingathinti ngokoqobo impahla, ngeke iyiphushe noma iyisuse phakathi nenqubo yokusika. Lokhu kuvumela imiklamo eyinkimbinkimbi nemininingwane enembayo, okwenza kube ukukhetha okuhle kwezindwangu kanye nesikhumba ngokufanayo. Ngakho-ke, uma uhlose ikhwalithi nokunemba, ukusika nge-laser kungase kube indlela okufanele uhambe ngayo!

Izindwangu Ezidinga Imininingwane Enhle

Ukusika imininingwane emincane, kuzoba nzima ukusika ummese ngenxa yobukhulu bommese. Ezimweni ezinjalo, imikhiqizo efana nezinsiza zezimpahla zokugqoka, nezinto ezifana neleyisi nendwangu yesikhala zizoba ezingcono kakhulu zokusika i-laser.

◼ Kungani kungenjalo Kokubili i-Laser & CNC Knife Cutter kumshini owodwa?

Umbuzo ojwayelekile esiwuzwa kumakhasimende ethu uthi: "Ingabe womabili amathuluzi angafakwa emshinini owodwa?" Nakuba kungase kuzwakale kulula, nazi izizathu ezimbili zokuthi kungani ungewona umqondo ongcono kakhulu:

Isistimu ye-Vacuum:Isistimu ye-vacuum kusisiki sommese iklanyelwe ukubamba indwangu phansi ngokucindezela, kuyilapho kusisiki nge-laser, ihloselwe ukuqeda intuthu ekhiqizwa ngesikhathi sokusika. Lawa masistimu anezinjongo ezihlukile futhi awashintsheki kalula. Njengoba sishilo ekuqaleni, abasiki be-laser kanye nommese bayaphelelisana ngokuphelele. Kufanele ukhethe ukutshala kokukodwa noma okunye ngokusekelwe ezidingweni zakho ezithile okwamanje.

I-Conveyor Belt:Abasiki bemimese ngokuvamile baye bazizwela ama-conveyors ukuvimbela imihuzuko phakathi kwendawo yokusika nezindwani. Nokho, ukusebenzisa i-laser kunganqamula lowo muzwa! Ngakolunye uhlangothi, abasiki be-laser bavame ukusebenzisa amatafula ensimbi anezikhala. Uma uzama ukusebenzisa ummese kuleyo ndawo, ungaba sengozini yokulimaza kokubili amathuluzi akho kanye nebhande lokudlulisa.

Ngamafuphi, nakuba ukuba nawo womabili amathuluzi emshinini owodwa kungase kubonakale kukhanga, izinto ezisebenzayo azihlanganisi! Kungcono ukunamathela ithuluzi elifanele lomsebenzi.

Ubani Okufanele Acabange Ukutshala I-Textile Laser Cutter?

Manje, ake sikhulume ngombuzo wangempela, ubani okufanele acabangele ukutshala imali emshinini wokusika we-laser wendwangu? Ngihlanganise uhlu lwezinhlobo ezinhlanu zamabhizinisi okufanele zicatshangelwe ukukhiqizwa kwe-laser. Bheka ukuthi ungomunye wabo yini

Ukukhiqizwa Kweziqephu Ezincane/ Ukwenza ngokwezifiso

Uma unikeza isevisi yokwenza ngokwezifiso, umshini wokusika i-laser uyisinqumo esihle. Ukusebenzisa umshini we-laser ekukhiqizeni kungalinganisa izidingo phakathi kokusika kahle kanye nekhwalithi yokusika

Izinto Ezisetshenziswa Kakhulu Ezibizayo, Imikhiqizo Yenani Eliphezulu Eyengezwe

Ngezinto zokwakha ezibizayo, ikakhulukazi indwangu yobuchwepheshe efana ne-Cordura ne-Kevlar, kungcono ukusebenzisa umshini we-laser. Indlela yokusika ngaphandle kokuthinta ingakusiza ukuthi wonge impahla ngezinga elikhulu. Siphinde sinikeze isofthiwe yokuzalela engahlela izingcezu zakho zedizayini ngokuzenzakalelayo.

Izimfuneko Eziphakeme Zokunemba

Njengomshini wokusika we-CNC, umshini we-CO2 laser ungafinyelela ukunemba kokusika ngaphakathi kwe-0.3mm. Unqenqema lokusika lushelela kunelo lokusika ummese, ikakhulukazi ukwenza indwangu. Ukusebenzisa irutha ye-CNC ukusika indwangu elukiwe, kuvame ukukhombisa imiphetho emagebhugebhu enemicu endizayo.

Umkhiqizi Wesiteji Sokuqala

Ukuqala, kufanele usebenzise ngokucophelela noma iyiphi imali onayo. Ngesabelomali samadola ayizinkulungwane ezimbalwa, ungasebenzisa ukukhiqiza okuzenzakalelayo. I-Laser ingaqinisekisa ikhwalithi yomkhiqizo. Ukuqasha izisebenzi ezimbili noma ezintathu ngonyaka kuzobiza kakhulu kunokutshala i-laser cutter.

Ukukhiqizwa Kwezandla

Uma ufuna uguquko, ukwandisa ibhizinisi lakho, ukhuphule umkhiqizo, futhi unciphise ukuthembela kubasebenzi, kufanele ukhulume nomunye wabameleli bethu bokuthengisa ukuthola ukuthi i-laser izoba yisinqumo esihle yini kuwe. Khumbula, umshini we-laser CO2 ungacubungula ezinye izinto eziningi ezingezona ezensimbi ngesikhathi esisodwa.

Uma ungomunye wabo, futhi unecebo lokutshala imali lokusika umshini wendwangu. I-automatic CO2 laser cutter izoba yisinqumo sakho sokuqala. Ilinde ukuba umlingani wakho othembekile!

I-Fabric Laser Cutter Ongayikhetha

Noma yikuphi Ukudideka noma Imibuzo Ye-Textile Laser Cutter

Vele Usibuze Noma Kunini

Isikhathi sokuthumela: Jan-06-2023