Yebo, ungakwazi ngokuphelele ukusika i-fiberglass usebenzisa umshini wokusika we-CO2 laser!

Ngenkathi i-fiberglass iqinile futhi ihlala isikhathi eside, i-laser ipakisha i-punch ngamandla ayo agxilile, isika kalula into.

I-beam encane kodwa enamandla ingena ngendwangu ye-fiberglass, amashidi, noma amaphaneli, ikushiye unokusikeka okuhlanzekile, okunembayo njalo.

I-laser cutting fiberglass ayisebenzi nje kuphela kodwa futhi iyindlela enhle yokuletha imiklamo yakho yokudala nezimo eziyinkimbinkimbi ngale nto esebenza ngezindlela eziningi. Uzomangala ukuthi ungadala ini!

Tshela nge-Fiberglass

I-Fiberglass, evame ukubizwa ngokuthi ipulasitiki eqiniswe ngengilazi (GRP), iyinhlanganisela ekhangayo eyakhiwe ngemicu yengilazi emihle elukwa ibe yi-resin matrix.

Le miksi ehlakaniphile ikunikeza okokusebenza okungasindi nje kuphela kodwa futhi kuqine ngendlela emangalisayo futhi kuguquguquke.

Uzothola i-fiberglass kuzo zonke izinhlobo zezimboni—isetshenziselwa yonke into kusukela ezingxenyeni zesakhiwo kanye nokwahlukanisa kuya kumagiya okuvikela emikhakheni efana ne-aerospace, ezezimoto, ezokwakha, nezolwandle.

Uma kuziwa ekusikeni nasekucubunguleni i-fiberglass, ukusebenzisa amathuluzi afanele kanye nezinyathelo zokuphepha kubalulekile ekwenzeni umsebenzi wenziwe ngokuphepha nangokunembile.

Ukusika i-laser kukhanya ngempela lapha, kukuvumela ukuthi ufinyelele lokho kusikeka okuhlanzekile, okuyinkimbinkimbi okwenza wonke umehluko!

I-Laser Cutting Fiberglass

I-laser cutting fiberglass imayelana nokusebenzisa i-laser enamandla amakhulu ukuze incibilike, ishise, noma ihwamulise into ethile endleleni ethile.

Okwenza le nqubo inembe kangaka isofthiwe ye-computer-aid design (CAD) elawula i-laser cutter, eqinisekisa ukuthi konke ukusika kunembile futhi akuguquki.

Enye yezinto ezinhle kakhulu ngokusika kwe-laser ukuthi isebenza ngaphandle kokuthintana ngokomzimba nezinto ezibonakalayo, okusho ukuthi ungafinyelela leyo miklamo eyinkimbinkimbi, enemininingwane kalula.

Ngejubane layo lokusika elisheshayo kanye nekhwalithi ephezulu, akumangalisi ukuthi ukusika nge-laser sekuyindlela ehamba phambili yokusebenza ngendwangu ye-fiberglass, amacansi, nezinto zokufakelwa!

Ividiyo: I-Laser Cutting Silicone-Coated Fiberglass

I-fiberglass ehlanganiswe ne-silicone iyisivikelo esimangalisayo ngokumelene nezinhlansi, isipatha, nokushisa, okuyenza ibe yigugu kuzo zonke izimboni ezihlukahlukene.

Nakuba ukusika ngommese noma imihlathi kungaba yinselele impela, ukusika nge-laser kwenza inqubo ingenzeki kuphela kodwa futhi ibe lula, ilethe ikhwalithi eyingqayizivele ngakho konke ukusikeka!

Ngokungafani namathuluzi okusika endabuko anjengama-jigsaw noma ama-Dremels, imishini yokusika i-laser isebenzisa indlela engathinteki ukuze ibhekane ne-fiberglass.

Lokhu kusho ukuthi akukho ukugqokwa kwamathuluzi futhi akukho monakalo ezintweni—ukwenza ukusika i-laser kube ukukhetha okufanele!

Kodwa yiluphi uhlobo lwe-laser okufanele ulusebenzise: I-Fiber noma i-CO₂?

Ukukhetha i-laser efanele kuyisihluthulelo sokuthola imiphumela engcono kakhulu lapho usika i-fiberglass.

Nakuba amalaser e-CO₂ evame ukutuswa, ake sihlole kokubili ama-CO₂ nama-fiber lasers ukuze sibone izinzuzo zawo kanye nemikhawulo yalo msebenzi.

I-CO2 Laser Cutting Fiberglass

Ubude begagasi:

Amalaser e-CO₂ ngokuvamile asebenza kubude begagasi obungama-micrometer angu-10.6, asebenza kahle kakhulu ekusikeni izinto ezingezona ezensimbi, okuhlanganisa i-fiberglass.

Ukusebenza kahle:

Ubude begagasi be-CO₂ lasers bumuncwa kahle yi-fiberglass material, okuvumela ukusika okuphumelelayo.

Ama-laser e-CO₂ ahlinzeka ngokusikeka okuhlanzekile, okunembile futhi angakwazi ukuphatha ubukhulu obuhlukahlukene be-fiberglass.

Izinzuzo:

1. Ukunemba okuphezulu nemiphetho ehlanzekile.

2. Afanele ukusika amashidi aminyene e-fiberglass.

3. Isungulwe kahle futhi isetshenziswa kabanzi kwizicelo zezimboni.

Imikhawulo:

1. Idinga ukunakekelwa okwengeziwe uma kuqhathaniswa namalaser efiber.

2. Ngokuvamile emikhulu futhi ebiza kakhulu.

I-Fiber Laser Cutting Fiberglass

Ubude begagasi:

Ama-fiber lasers asebenza kubude obungamaza acishe abe ngu-1.06 micrometer, afaneleka kakhulu ukusika izinsimbi futhi angasebenzi kahle ezintweni ezingezona ezensimbi njenge-fiberglass.

Ukuba nokwenzeka:

Ngenkathi ama-fiber lasers angasika ezinye izinhlobo ze-fiberglass, ngokuvamile awasebenzi kahle kunama-CO₂ lasers.

Ukumuncwa kwe-wavelength ye-fiber laser nge-fiberglass kuphansi, okuholela ekusikeni okusebenza kahle kakhulu.

Umthelela Wokusika:

Ama-laser e-fiber angase angahlinzeki ngokusikeka okuhlanzekile nokunembe ku-fiberglass njengamalaser e-CO₂.

Amaphethelo angase abe mahle, futhi kungase kube nezinkinga ngokusikeka okungaphelele, ikakhulukazi ngezinto eziwugqinsi.

Izinzuzo:

1. Amandla aphezulu aphezulu kanye nesivinini sokusika izinsimbi.

2. Izindleko eziphansi zokunakekela kanye nokusebenza.

3.Iqinile futhi iyasebenza.

Imikhawulo:

1. Ayisebenzi kahle ezintweni ezingezona ezensimbi njenge-fiberglass.

2. Ingase ingafinyeleli ikhwalithi yokusika efiselekayo yezinhlelo zokusebenza ze-fiberglass.

Indlela yokukhetha i-laser yokusika i-fiberglass?

Nakuba i-fiber lasers iphumelela kakhulu ekusikeni izinsimbi futhi inikeza izinzuzo ezimbalwa

Ngokuvamile abayona inketho engcono kakhulu yokusika ingilazi ye-fiberglass ngenxa yobude bawo beza kanye nezici zokumuncwa kwempahla.

Ama-laser e-CO₂, anobude bawo obude, afaneleka kakhulu ukusika ingilazi ye-fiberglass, anikeze ukusikeka okuhlanzekile nokunembe kakhudlwana.

Uma ubheke ukusika i-fiberglass kahle nangekhwalithi ephezulu, i-CO₂ laser iyindlela enconyiwe.

Uzothola ku-CO2 Laser Cutting Fiberglass:

✦Ukumuncwa Okungcono:Ubude begagasi be-CO₂ lasers bumuncwa kangcono i-fiberglass, okuholela ekusikeni okusebenza kahle nokuhlanzeka kakhudlwana.

✦ Ukuhambisana Kwezinto:Ama-laser e-CO₂ aklanyelwe ngokukhethekile ukusika izinto ezingezona ezensimbi, azenze zilungele i-fiberglass.

✦ Ukuhlukahluka: Ama-laser e-CO₂ angakwazi ukuphatha ukujiya okuhlukahlukene nezinhlobo ze-fiberglass, enikeza ukuguquguquka okwengeziwe ekukhiqizeni nasekusetshenzisweni kwezimboni. Njenge-fiberglassukwahlukanisa, indawo yasolwandle.

| Indawo yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isofthiwe | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Isinyathelo Motor Belt Control |

| Ithebula Lokusebenza | I-Honey Comb Working Table noma I-Knife Strip Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Izinketho: Thuthukisa i-Laser Cut Fiberglass

I-Auto Focus

Kungase kudingeke ukuthi usethe ibanga elithile lokugxila kusofthiwe lapho izinto zokusika zingekho flat noma ezinobukhulu obuhlukile. Bese ikhanda le-laser lizokwehla liye phezulu ngokuzenzakalelayo, ligcine ibanga elifanelekile lokugxila endaweni ebonakalayo.

I-Servo Motor

I-servomotor iyi-servomotor evaliwe esebenzisa impendulo yendawo ukuze ilawule ukunyakaza kwayo kanye nendawo yokugcina.

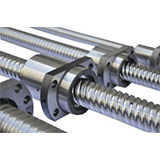

I-Ball Screw

Ngokuphambene nezikulufu zokuhola ezivamile, izikulufu zebhola zivamise ukuba nkulu, ngenxa yesidingo sokuba nendlela yokuzungeza kabusha amabhola. Isikulufu sebhola siqinisekisa isivinini esikhulu kanye nokusikwa kwe-laser ngokunemba okuphezulu.

| Indawo yokusebenza (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Isofthiwe | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Ukudlulisa Ibhande & Isinyathelo Motor Drive |

| Ithebula Lokusebenza | I-Honey Comb Working Table / I-Cnife Strip Ithebula Lokusebenza / Ithebula Lokusebenza Lokuthutha |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Izinketho: Thuthukisa i-Laser Cutting Fiberglass

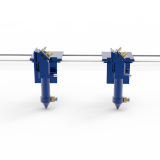

Amakhanda we-Laser Dual

Ngendlela elula neyomnotho kakhulu yokusheshisa ukusebenza kahle kwakho kokukhiqiza ukukhweza amakhanda e-laser amaningi endaweni eyodwa bese usike iphethini efanayo ngesikhathi esisodwa. Lokhu akuthathi indawo eyengeziwe noma umsebenzi.

Uma uzama ukusika imiklamo eminingi ehlukene futhi ufuna ukonga impahla ngezinga elikhulu, iI-Nesting Softwarekuzoba yisinqumo esihle kuwe.

II-Auto feederkuhlanganiswe ne-Conveyor Table yisisombululo esifanele sochungechunge nokukhiqizwa ngobuningi. Ithutha izinto eziguquguqukayo (indwangu isikhathi esiningi) ukusuka kumqulu kuya kunqubo yokusika ohlelweni lwe-laser.

Ingakanani i-Fiberglass engakwazi ukusika i-laser?

Ngokuvamile, i-CO₂ laser inganqamula amaphaneli e-fiberglass aminyene afinyelele ku-25mm kuya ku-30mm.

Ngohlu lwamandla e-laser asuka ku-60W kuya ku-600W, amanzi aphezulu asho amandla amakhulu okusika izinto eziwugqinsi.

Kodwa akukhona nje ukujiya; uhlobo lwe-fiberglass material nalo ludlala indima ebalulekile. Ukuqanjwa okuhlukile, izici, nezisindo zegremu zingathinta kakhulu ukusebenza nekhwalithi yokusika i-laser.

Kungakho kubalulekile ukuhlola impahla yakho ngomshini wokusika we-laser ochwepheshe. Ochwepheshe bethu be-laser bazohlaziya izici ezithile ze-fiberglass yakho futhi bakusize uthole ukumiswa komshini ophelele kanye nemingcele yokusika efanele!

Ingabe i-Laser Ingayisika i-G10 Fiberglass?

I-G10 fiberglass iyilaminate eqinile enengcindezi ephezulu eyenziwe ngokunqwabelanisa izingqimba zendwangu yengilazi efakwe ku-epoxy resin futhi icindezele ngaphansi kwengcindezi ephezulu. Umphumela uba into ewugqinsi, eqinile eyaziwa ngezici zayo ezinhle kakhulu zomshini kanye nezokuvikela ugesi.

Uma kuziwa ekusikeni i-G10 fiberglass, amalaser e-CO₂ awukubheja kwakho okuhle kakhulu, aletha ukusikeka okuhlanzekile, okunembayo njalo.

Ngenxa yezici zayo ezihlaba umxhwele, i-G10 fiberglass ilungele ukusetshenziswa okuhlukahlukene, kusukela ekufakeni ugesi kuya ezingxenyeni ezisebenza kahle kakhulu.

Inothi elibalulekile: I-laser yokusika i-G10 fiberglass ingakhipha intuthu enobuthi nothuli olucolekile, ngakho-ke kubalulekile ukukhetha isisiki se-laser esiphrofeshinali esinomshini oklanywe kahle wokungenisa umoya kanye nesistimu yokuhlunga.

Ngaso sonke isikhathi beka phambili izinyathelo zokuphepha ezifanele, okuhlanganisa ukungena komoya okuphumelelayo nokuphathwa kokushisa, ukuze uqinisekise imiphumela yekhwalithi ephezulu kanye nendawo yokusebenza ephephile lapho usikwa i-G10 fiberglass!

Noma yimiphi imibuzo mayelana ne-Laser Cutting Fiberglass

Khuluma Nongcweti Wethu we-Laser!

Noma yimiphi imibuzo mayelana ne-Laser Cutting Fiberglass Sheet?

Isikhathi sokuthumela: Mar-25-2025