Indlela Yokusika I-Sandpaper: Izindlela Ezilula Zokulinganisa Usayizi Oqondile

umshini wokusika we-sandpaper

Ufuna ukwazi kahle ukuthi ungasika kanjani i-sandpaper njengochwepheshe? Kungakhathaliseki ukuthi wenza umsebenzi wezandla onembile noma wenza isihlabathi semboni, ukuthola ukusikeka okuhlanzekile kubalulekile. Sizokubonisa indlela ehlakaniphile yokunquma amashidi nokubhoboza izimbobo zothuli - kanye namathuluzi angcono kakhulu emisebenzi yezandla noma yomshini.

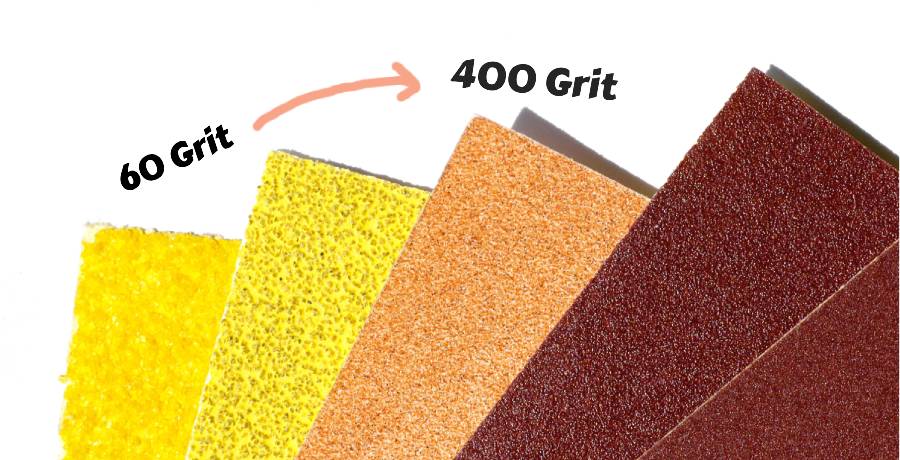

Izinhlobo Eziyinhloko zeGrit

Iphepha lesandpaper liza ngezinhlobo ezahlukene zegrit(abrasive), ngayinye yakhelwe izinhlelo zokusebenza ezithile. Izinhlobo ezivame kakhulu zihlanganisa i-aluminium oxide, i-silicon carbide, i-ceramic, ne-garnet sandpaper. Uhlobo ngalunye lunezinto ezihlukile ezilungele imisebenzi eyahlukene:

• I-Aluminium oxide: Ihlala isikhathi eside futhi iguquguqukayo, ilungele ukhuni nesihlabathi sensimbi.

•I-Silicon Carbide: Ibukhali futhi iqinile, ilungele ukusika izinto eziqinile njengengilazi nepulasitiki.

•I-Ceramic: Ihlala isikhathi eside kakhulu futhi isebenza kahle ekugayeni isihlabathi nokugaya.

•I-Garnet: Ithambile futhi ivumelana nezimo, ngokuvamile isetshenziselwa umsebenzi wokhuni omuhle.

Ayini amabanga ama-3 e-sandpaper?

Iphepha lesandpaper lihlukaniswa libe amamaki afana nefine, amaholoholo namaphakathi futhi ngalinye lalawa mabanga liqukethe amazinga ahlukene achazwa yilokho okwaziwa njengegrit.

•Kumahhadla: Ukuze wenze isihlabathi esindayo futhi ukhumule, udinga igrit ye-sandpaper eqinile enobubanzi obungu-40- kuya ku-60-grit.

•Okumaphakathi:Ukuze uthole izindawo ezibushelelezi futhi ukhiphe ukungapheleli okuncane, khetha i-sandpaper ephakathi ukusuka ku-80- kuya ku-120-grit sandpaper.

•Okuhle:Ukuze uqedele izindawo ngokushelelayo, sebenzisa i-sandpaper enhle kakhulu enamagrit angama-400 kuya ku-600.

Iphepha lesandpaper lisetshenziswa ezimbonini eziningi ezihlanganisa ezokwakha izinkuni, ezezimoto, ezensimbi nezokwakha.

Ibalulekile emisebenzini efana nokushelela, ukususa upende noma ukugqwala, nokulungiselela izinto zokuqeda.

▶ Ummese Wokusetshenziswa

Ngokusika ngesandla, ummese wokusetshenziswa one-straightedge uyindlela elula kodwa ephumelelayo.

Ivamise ukusetshenziswa kuma-workshops amancane lapho ukunemba kokusika nevolumu kulawulwa ngesandla.

▶ Ithuluzi le-Dremel

Ithuluzi le-Dremel elinesinamathiselo sokusika lingasetshenziselwa ukusikeka okuncane, okuningiliziwe.

Ifaneleka kakhulu kwabathanda ukuzilibazisa noma ukukhiqizwa kwezinga elincane lapho kudingeka khona ukuguquguquka.

▶ I-Rotary Paper Cutter

Ama-Rotary paper cutters awusizo ekwenzeni ukusikeka okuqondile kumashidi e-sandpaper.

Ngokufanayo nesinqamuli sephepha, sisebenzisa i-blade ejikelezayo ukusika i-sandpaper.

Njengethuluzi lokusika lemanuwali, umsiki wephepha ojikelezayo akakwazi ukuqinisekisa ukunemba nokusheshisa ukusika.

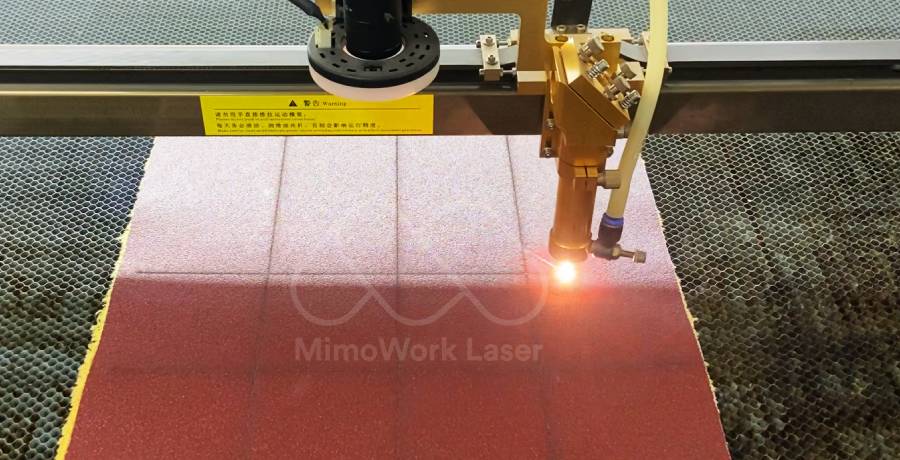

I-Laser Cutter

Ama-Laser cutter anembe kakhulu, awenza alungele ukubunjwa ngokwezifiso kanye nemiklamo eyinkimbinkimbi.

Basebenzisa umsebe wokukhanya ogxilile ukuze banqamule i-sandpaper, baqinisekise imiphetho ehlanzekile ngaphandle kokubola.

I-Laser cutter inemisebenzi eminingi yokusika izimbobo ezincane futhi isike ibe yizimo nobukhulu obuhlukahlukene.

Ngenxa yesistimu ye-CNC kanye nokucushwa komshini okuthuthukisiwe, ikhwalithi yokusika i-sandpaper nokusebenza kahle kokusika kungenziwa emshinini owodwa.

I-Die Cutter

Abasiki be-Die basebenzisa idayi emise okwengaphambili ukuze bakhiphe imilo ethile emakhasini noma kumaroli e-sandpaper.

Asebenza kahle ekukhiqizeni ivolumu ephezulu lapho ukufana kubalulekile.

Umkhawulo we-die cutter ukuguga kwamathuluzi abrasive. Uma sifuna ukusika amajamo amasha kanye nemiklamo emisha ye-sandpaper, sidinga ukuthenga ama-dies amasha. Kuyabiza lokho.

Idinga ukunemba okuphezulu nokwenza ngendlela oyifisayo:

Uma ukunemba kokusika nokuthi kungenziwa ngokwezifiso kungukukhathazeka kwakho, i-Laser Cutter iyisinqumo sakho esifanele.

I-Laser cutting sandpaper inikeza ukunemba okungenakuqhathaniswa, ukuguquguquka, nokusebenza kahle.

Ilungele kokubili ukukhiqizwa kwezinga elincane kanye nenani elikhulu lapho kudingeka khona imiklamo yekhwalithi ephezulu, eyinkimbinkimbi.

Ukutshalwa kwezimali kokuqala kuphezulu, kodwa izinzuzo mayelana nokunemba nokuguquguquka zikwenza kube nenzuzo.

Qaphela Ukusebenza Okuphezulu Nomphumela Wokukhiqiza

Ekhuluma ngokusika kahle,i-die cutter ingumnqobi ngoba isike i-sandpaper ngama-pre-shaped dies.

Uma unomklamo ofanayo kanye nephethini, i-die cutter ingaqeda ngokushesha ukusika. Lokho kulungele ukukhiqizwa ngobuningi bomklamo ofanayo we-sandpaper.

Kepha uma unezidingo ezahlukahlukene zomumo we-sandpaper, ubukhulu, amaphethini wokuklama, i-die cutter ayiyona engcono kakhulu uma iqhathaniswa ne-laser cutter.

Idizayini entsha idinga ukufa okusha, okudla isikhathi futhi kuyabiza ukusika ukufa. Ngokuphambene,i-laser cutter ingahlangabezana nezimo ezenziwe ngokwezifiso nezihlukahlukene zokusika emshinini owodwa.

Okokusebenza okugxile kwisabelomali

Ngokucabangela izindleko zomshini,amathuluzi okwenziwa ngesandla afana ne-rotary cutter ne-Dremel ayonga kakhulu, futhi anokuguquguquka okuthile kokusebenza.

Zifanele imisebenzi emincane noma lapho izithiyo zebhajethi ziyisici esibalulekile.

Nakuba imanuwali ingenakho ukunemba nokusebenza kahle kwabasiki be-laser, iyafinyeleleka futhi iyonga kakhulu emisebenzini elula.

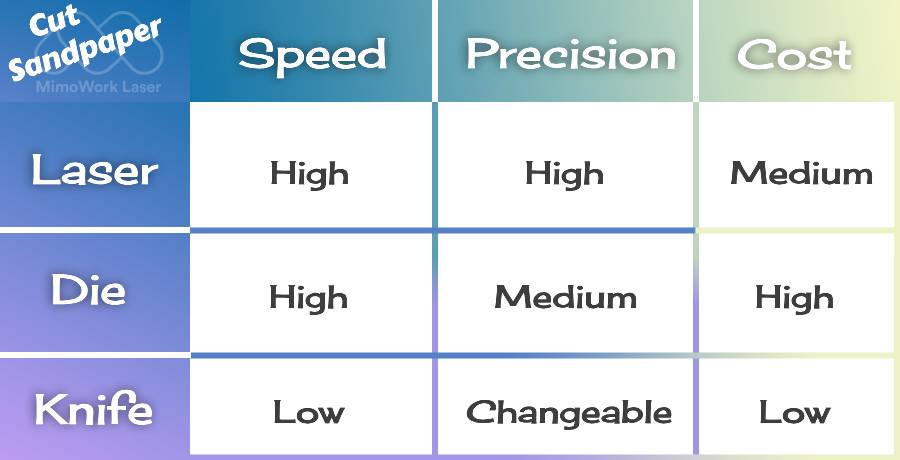

Ukuqhathanisa Amathuluzi Amathathu

Ukusika i-sandpaper, ukukhethwa kwethuluzi kuncike kakhulu ezidingweni ezithile zokusebenza.

Abasiki be-laser bagqama njengesinqumo esingcono kunazo zonke sokunemba kwabo, ukuguquguquka, nokusebenza kahle, ikakhulukazi uma usebenzelana nemiklamo eyinkimbinkimbi nama-oda enziwe ngokwezifiso.

Ama-Die cutters ayasebenza ekukhiqizeni okuphezulu, okungaguquki.

Nakuba abasiki be-rotary banikeza inketho evumelana nesabelomali semisebenzi emincane, eyinkimbinkimbi.

Ngokuhlola izidingo zakho ezithile kanye nesikali sokukhiqiza, ungakhetha ithuluzi elifaneleka kakhulu ukuze uzuze imiphumela emihle ekusikeni i-sandpaper.

I-Sandpaper Emise Ngokwezifiso Yamathuluzi Akhethekile

Amandla Sanders: Ukusika i-laser kuvumela ukudalwa okunembayo kwe-sandpaper elingana nokwakheka kwe-sander yamandla athile, njenge-orbital, ibhande, nama-disc sanders. Lokhu kuqinisekisa ukusebenza kahle nokusebenza kahle.

Imininingwane Sanders: Amajamo angokwezifiso angasikwa ukuze alingane nama-sander wemininingwane asetshenziswa emisebenzini eyinkimbinkimbi yokwenza ukhuni noma yokuqeda.

Precision-Sika Sandpaper for Industrial Use

Imboni Yezimoto: I-laser-cut sandpaperisetshenziselwa ukuqedela nokupholisha izingxenye zezimoto, lapho umumo nosayizi abanembile kubalulekile ukuze uthole imiphumela engaguquki.

Imboni ye-Aerospace: Imboni ye-aerospace idinga ukunemba okuphezulu kokulungiswa kwendawo kanye nokuqedwa. I-laser-cut sandpaper ihlangabezana nalezi zindinganiso eziqinile.

Imisebenzi Yezandla Nezokuzilibazisa

DIY Projects: Abathanda izinto zokuzilibazisa kanye nabathandi be-DIY bayazuza ku-laser-cut sandpaper ukuze bathole umsebenzi onemininingwane ngezinto ezihlukahlukene, okuhlanganisa ukhuni, insimbi, nepulasitiki.

Ukwenza Imodeli: I-sandpaper enqunywe ngokunemba ilungele abenzi bamamodeli abadinga izingcezu ezincane, ezimise okuyinkimbinkimbi ukuze benze imisebenzi emihle ye-sanding.

Ifenisha kanye Nokwenza Ngokhuni

Ukubuyiselwa Kwefenisha: I-laser-cut sandpaper ingalungiswa ukuze ilingane namakhonsathi athile kanye nezimo zezingcezu zefenisha, okuvumela umsebenzi wokubuyisela onemininingwane.

Ukubaza: Abasebenza ngokhuni bangasebenzisa i-sandpaper emise okwezifiso ukuze bathole imininingwane eminingi yemidwebo, imiphetho, namalunga.

Izicelo Zezokwelapha Nezamazinyo

I-Orthopedic Sanding: I-sandpaper emise okwezifiso isetshenziswa emkhakheni wezokwelapha ekulungiseleleni amadivaysi e-orthopedic nama-prosthetics.

Amathuluzi Amazinyo: I-sandpaper enqunywe ngokunemba isetshenziswa ezinkambisweni zamazinyo ukupholisha nokuqedela izitho zokwenziwa zamazinyo nezinto zikagesi.

Iphepha lesandpaper elinamaphethini embobo yangokwezifiso

Izinhlelo Zokukhipha Uthuli: Ukusika i-laser kuvumela ukubekwa okunembile kwezimbobo ku-sandpaper ukuze kuhambisane nezinhlelo zokukhipha uthuli, okuthuthukisa ukusebenza kahle nokuhlanzeka ngesikhathi sokutshala isihlabathi.

Ukusebenza Okuthuthukisiwe: Amaphethini embobo ngokwezifiso angathuthukisa ukusebenza kwe-sandpaper ngokunciphisa ukuvala nokwandisa ubude bayo bempilo.

Ubuciko Nokuklama

Amaphrojekthi Wokudala: Amaciko nabaqambi basebenzisa i-laser-cut sandpaper ngezingcezu zobuciko eziyingqayizivele, lapho kudingeka khona ukunemba nemiklamo eyinkimbinkimbi.

Ukwakheka Kombhalo: Ukwakheka ngokwezifiso namaphethini kungadalwa ku-sandpaper ngemiphumela ethile yobuciko.

Izinsimbi & Igiya Lezemidlalo

Insimbi:I-laser-cut sandpaper isetshenziswa ekukhiqizeni iziginci ukuze bushelelezi futhi baqedele umzimba, intamo, kanye ne-fretboard. Lokhu kuqinisekisa isiphetho sekhwalithi ephezulu kanye nokudlala ntofontofo.

Igiya Lezemidlalo:Isibonelo, ama-skateboards ngokuvamile adinga i-sandpaper, eyaziwa kakhulu ngokuthi i-grip tape, ukuthi ifakwe edekhini ukuze kuthuthukiswe ukudonsa nokulawula.

Ilungele ukusika, ukubhoboza, ukuqopha

I-Laser Cutter yeSandpaper

| Indawo yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Isinyathelo Motor Belt Control |

| Ithebula Lokusebenza | I-Honey Comb Working Table noma I-Knife Strip Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

| Usayizi Wephakheji | 2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

| Isisindo | 620kg |

| Indawo yokusebenza (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Indawo Yokuqoqa (W * L) | 1600mm * 500mm (62.9'' * 19.7'') |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W / 150W / 300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Ukudlulisa Ibhande & Isinyathelo Motor Drive / Servo Motor Drive |

| Ithebula Lokusebenza | Ithebula Lokusebenza Le-Conveyor |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

| Indawo yokusebenza (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Ukulethwa kwe-Beam | I-3D Galvanometer |

| Laser Amandla | 180W/250W/500W |

| Umthombo we-Laser | CO2 RF Metal Laser Tube |

| Uhlelo lweMechanical | I-Servo Driven, I-Belt Driven |

| Ithebula Lokusebenza | I-Honey Comb Working Table |

| Isivinini sokusika esiphezulu | 1 ~ 1000mm/s |

| Isivinini esikhulu sokumaka | 1~10,000mm/s |

Funda kabanzi mayelana ne-laser cutting sandpaper

Noma yimiphi imibuzo mayelana ne-Laser Cut Sandpaper?

Isikhathi sokuthumela: Jul-02-2024