Indlela Yokusika Indwangu Yenayiloni Ye-Laser?

Inayiloni Laser Cutting

Imishini yokusika i-laser iyindlela ephumelelayo nephumelelayo yokusika nokuqopha izinto ezihlukahlukene, kuhlanganise nenayiloni. Ukusika indwangu yenayiloni nge-laser cutter kudinga ukucatshangelwa okuthile ukuze kuqinisekiswe ukusika okuhlanzekile nokunembile. Kulesi sihloko, sizoxoxa ngendlela yokusika inayiloni ngeindwangu laser cutting umshinifuthi uhlole izinzuzo zokusebenzisa umshini wokusika inayiloni othomathikhi kule nqubo.

Okokufundisa Kokusebenza - Ukusika Indwangu Yenayiloni

1. Lungiselela Ifayela Lokuklama

Isinyathelo sokuqala sokusika indwangu yenayiloni nge-laser cutter ukulungisa ifayela lokuklama. Ifayela lokuklama kufanele lidalwe kusetshenziswa isofthiwe esekwe kwi-vector njenge-Adobe Illustrator noma i-CorelDRAW. Umklamo kufanele udalwe ngobukhulu obuqondile beshidi lendwangu yenayiloni ukuze kuqinisekiswe ukusika okunembile. EyethuI-MimoWork Laser Cutting Softwareisekela iningi lefomethi yefayela lokuklama.

2. Khetha Izilungiselelo Ezilungile Zokusika I-Laser

Isinyathelo esilandelayo ukukhetha izilungiselelo ezifanele zokusika i-laser. Izilungiselelo zizohluka kuye ngokuqina kwendwangu yenayiloni kanye nohlobo lwesisiki se-laser esisetshenziswayo. Ngokuvamile, i-CO2 laser cutter enamandla angu-40 kuya ku-120 watts ifaneleka ukusika indwangu yenayiloni. Kwesinye isikhathi lapho ufuna ukusika indwangu yenayiloni engu-1000D, 150W noma amandla e-laser aphezulu ayadingeka. Ngakho-ke kungcono kakhulu ukuthumela i-MimoWork Laser impahla yakho ukuze ihlolwe isampula.

Amandla we-laser kufanele abekwe ezingeni elizoncibilikisa indwangu yenayiloni ngaphandle kokuyishisa. Ijubane lelaser kufanele futhi libekwe ezingeni elizovumela i-laser ukuthi inqamule indwangu yenayiloni ngokushelela ngaphandle kokudala imiphetho ejijekile noma imiphetho ephukile.

Funda kabanzi mayelana nemiyalelo yokusika inayiloni laser

3. Vikela Indwangu Yenayiloni

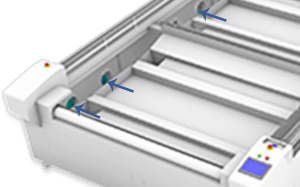

Uma izilungiselelo zokusika i-laser sezilungisiwe, sekuyisikhathi sokuvikela indwangu yenayiloni embhedeni wokusika we-laser. Indwangu yenayiloni kufanele ibekwe phezu kombhede wokusika futhi ivikelwe nge-tape noma izinsimbi ukuze ivimbele ukuhamba ngesikhathi sokusika. Wonke umshini wokusika we-laser we-MimoWork unawouhlelo lwe-vacuumngaphansi kweitafula lokusebenzalokho kuzodala ukucindezela komoya ukulungisa indwangu yakho.

Sinezindawo ezahlukene zokusebenza ze-umshini wokusika we-laser flatbed, ungakhetha evumelana nezidingo zakho. Noma ungasibuza ngokuqondile.

4. Isivivinyo Sika

Ngaphambi kokusika umklamo wangempela, kuwumqondo omuhle ukwenza ukusika kokuhlola ocezwini oluncane lwendwangu yenayiloni. Lokhu kuzosiza ekunqumeni ukuthi izilungiselelo zokusika i-laser zilungile futhi uma kukhona ukulungiswa okudingeka kwenziwe. Kubalulekile ukuhlola ukusika ohlotsheni olufanayo lwendwangu yenayiloni ezosetshenziswa kuphrojekthi yokugcina.

5. Qala Ukusika

Ngemuva kokuthi ukusika kokuhlolwa sekuqediwe futhi izilungiselelo zokusika i-laser zilungisiwe, sekuyisikhathi sokuqala ukusika umklamo wangempela. I-laser cutter kufanele iqalwe, futhi ifayela lokuklama kufanele lilayishwe kusofthiwe.

Umsiki we-laser uzobe esesika indwangu yenayiloni ngokwefayela lokuklama. Kubalulekile ukuqapha inqubo yokusika ukuze uqinisekise ukuthi indwangu ayishisi ngokweqile, futhi i-laser isika kahle. Khumbula ukuvula i-i-exhaust fan kanye nepompo yomoyaukwandisa umphumela wokusika.

6. Ukuqeda

Izingcezu ezisikiwe zendwangu yenayiloni zingase zidinge ukuthinta okuthile ukuze bushelelezi noma yikuphi unqenqema olumahhadlahhadla noma ukususa noma yikuphi ukuguquguquka okubangelwa inqubo yokusika i-laser. Kuye ngesicelo, izingcezu ezisikiwe zingadinga ukuthungwa ndawonye noma zisetshenziswe njengezicucu ngazinye.

Izinzuzo Zemishini Yokusika Inayiloni Ezenzakalelayo

Ukusebenzisa umshini wokusika inayiloni othomathikhi kungenza lula inqubo yokusika indwangu yenayiloni. Le mishini yakhelwe ukulayisha ngokuzenzakalelayo futhi isike inqwaba yendwangu yenayiloni ngokushesha nangokunembile. Imishini yokusika inayiloni ezenzakalelayo iwusizo ikakhulukazi ezimbonini ezidinga ukukhiqizwa ngobuningi bemikhiqizo enayiloni, njengezimboni zezimoto nezasemoyeni.

FAQ

Yebo, ungakwazi ukusika inayiloni nge-CO₂ laser, futhi inikeza imiphetho ehlanzekile, evaliwe kanye nokunemba okuphezulu, okuyenza ilungele izindwangu nezindwangu zezimboni. Kodwa-ke, inayiloni ikhiqiza intuthu enamandla futhi engaba yingozi lapho isikwa nge-laser, ngakho-ke ukungena komoya ngendlela efanele noma ukukhipha intuthu kubalulekile. Njengoba inayiloni incibilika kalula, izilungiselelo ze-laser kufanele zilungiswe ngokucophelela ukuze kugwenywe ukushiswa noma ukuhlanekezela. Ngezinyathelo ezifanele zokusetha nezokuphepha, ukusika i-CO₂ laser kuyindlela ephumelelayo nephumelelayo yokucubungula izinto zenayiloni.

Inayiloni iphephile ukuthi ingasikwa nge-laser uma kukhishwe intuthu efanele. Inayiloni yokusika ikhipha iphunga elinamandla namagesi angaba yingozi, ngakho-ke kunconywa ukusebenzisa umshini ovalekile onokungenisa komoya.

Inayiloni yokusika i-laser inikeza ukunemba okungaxhunywanga, imiphetho evaliwe, ukubola okuncishisiwe, kanye nekhono lokudala amaphethini ayinkimbinkimbi. Iphinde ithuthukise ukukhiqiza ngokuqeda isidingo sokusebenza ngemuva kokucubungula.

Kunconyiwe Indwangu Laser Cutter

Izinto Ezihlobene Ukusika laser

Isiphetho

Indwangu ye-laser yokusika inayiloni iyindlela enembile nephumelelayo yokusika imiklamo eyinkimbinkimbi kumpahla. Inqubo idinga ukucatshangelwa ngokucophelela kwezilungiselelo zokusika i-laser, kanye nokulungiswa kwefayela lokuklama nokuvikeleka kwendwangu embhedeni wokusika. Ngomshini wokusika we-laser ofanele kanye nezilungiselelo, ukusika indwangu yenayiloni nge-laser cutter kungaveza imiphumela ehlanzekile nenembile. Ukwengeza, ukusetshenziswa komshini wokusika inayiloni othomathikhi kungenza kube lula inqubo yokukhiqiza ngobuningi. Kungakhathaliseki ukuthi isetshenziselwaizingubo nemfashini, izinhlelo zokusebenza zezimoto, noma ze-aerospace, ukusika indwangu yenayiloni nge-laser cutter kuyisixazululo esisebenza ngezindlela eziningi nesisebenzayo.

Funda kabanzi mayelana nomshini wokusika inayiloni laser?

Isikhathi sokuthumela: May-12-2023