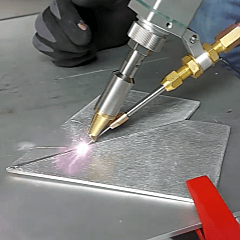

Indlela Yokwenza I-Laser Weld Aluminium Alloys

Ukushisela i-Aluminium Kungaba Luqili

Ama-alloys e-aluminium ahlukaniswa ngochungechunge ngokusekelwe kuma-elementi awo ayisisekelo.

Uchungechunge ngalunye lunezici ezihlukile ezithinta ukushisela kwalo, ikakhulukazi uma kusetshenziswa i-laser welding ephathwayo.

Ngezansi ukubuka konke kochungechunge olujwayelekile lwe-aluminium alloy, izici zalo, amagesi avikelayo afanelekile, izintambo zokugcwalisa ezifanele, namathiphu okuzuza ukushisela kwekhwalithi ephezulu.

Uhlu Lokuqukethwe:

1. Ama-Aluminium Alloys Avamile we-Laser Welding

Isinyathelo sokuqala sokuzuza i-Weld enhle: Ukuqonda

1000 Series Aluminium Alloys

Ukwakhiwa:Iqukethe 99.00% aluminium noma ngaphezulu.

Izakhiwo:Ilula futhi i-ductile kakhulu, okwenza kube lula ukusebenza ngayo.

I-Shielding Gas:100% Argon Kunconywa ukuvimbela oxidation.

Intambo Yokugcwalisa:Sebenzisa intambo yokugcwalisa engu-4047 noma engu-4045 ukuze ihambisane kangcono.

Amathiphu Welding:Qinisekisa ukuthi ingaphezulu lihlanzekile futhi alinawo ama-oxide. Ukushisa kuqala akudingekile ngenxa ye-ductility yayo ephezulu.

2000 Series Aluminium Alloys

Ukwakhiwa:I-alloyed ngokuyinhloko ngethusi (2-10%).

Izakhiwo:Amandla aphezulu kodwa i-ductility ephansi; ojwayele ukuqhekeka ngesikhathi sokushisela.

I-Shielding Gas:I-Argon enephesenti elincane le-Helium ingasiza ekuthuthukiseni ukungena.

Intambo Yokugcwalisa:Sebenzisa izintambo zokugcwalisa ezingu-4047 noma ezingu-2319, eziklanyelwe ama-alloys anothe ngethusi.

Amathiphu Welding:Shisisa izinto ukuze unciphise ingozi yokuqhekeka. Lawula okokufaka kokushisa ngokucophelela ukuze ugweme ukucindezelwa okushisayo okudlulele.

3000 Series Aluminium Alloys

Ukwakhiwa:Ihlanganiswe ne-manganese.

Izakhiwo:Ukumelana nokugqwala okuhle namandla; igcina amandla emazingeni okushisa aphakeme.

I-Shielding Gas:I-100% i-Argon iyasebenza.

Intambo Yokugcwalisa:I-4045 noma i-4047 yocingo yokugcwalisa ifanelekile.

Amathiphu Welding:Hlanza indawo engaphezulu ukuze ususe noma yikuphi ukungcola. Gcina isivinini sokuhamba esiqinile ukuze uqinisekise nokusabalaliswa kokushisa.

4000 Series Aluminium Alloys

Ukwakhiwa:Iqukethe i-silicon, eyehlisa indawo yokuncibilika.

Izakhiwo:I-ductility eyandisiwe futhi enhle kakhulu yokukhipha ukufa; okungelapheki ukushisa.

I-Shielding Gas:I-Argon iyakhethwa.

Intambo Yokugcwalisa:Sebenzisa intambo yokugcwalisa engu-4047 ukuze uthole imiphumela emihle.

Amathiphu Welding:Ukushisa kuqala kungasiza ngokungena. Gada okokufaka ukushisa eduze ukuze ugweme ukungqubuzana.

5000 Series Aluminium Alloys

Ukwakhiwa:Ihlanganiswe ne-magnesium.

Izakhiwo:Amandla aphezulu kanye nokumelana nokugqwala okuhle kakhulu; afanele amashidi namapuleti.

I-Shielding Gas:100% Argon Kunconywa.

Intambo Yokugcwalisa:Sebenzisa intambo yokugcwalisa engu-5356 ukuze ihambisane kangcono.

Amathiphu Welding:Ukushisa kuqala kunenzuzo ezingxenyeni ezijiyile. Sebenzisa inqubo yokucindezela ukuze uthuthukise isenzo sokuhlanza nokunciphisa ukungcola.

6000 Series Aluminium Alloys

Ukwakhiwa:Iqukethe kokubili i-magnesium ne-silicon.

Izakhiwo:I-ductility enhle futhi iphathwa ngokushisa; ilungele ama-extrusions.

I-Shielding Gas:I-Argon noma ingxube ye-Argon ne-Helium.

Intambo Yokugcwalisa:I-4045 noma i-5356 yocingo yokugcwalisa ifanelekile.

Amathiphu Welding:Qinisekisa ukuhlanzwa kahle kwendawo. Sebenzisa isivinini sokuhamba esiphezulu ukuvimbela ukushisa ngokweqile.

7000 Series Aluminium Alloys

Ukwakhiwa:Ngokuyinhloko ihlanganiswe ne-zinc.

Izakhiwo:Amandla aphezulu kodwa ngokuvamile awafaneleki ukushisela i-fusion ngenxa yezinkinga zokuqhekeka.

I-Shielding Gas:I-Argon ene-Helium ingaba yinzuzo.

Intambo Yokugcwalisa:Sebenzisa intambo yokugcwalisa engu-7072 noma engu-7005.

Amathiphu Welding:Ukushisa kwangaphambi kwesikhathi kubalulekile ukunciphisa ingozi yokuqhekeka. Sebenzisa okokufaka okulawulwayo okushisa futhi ugweme isivinini sokuhamba eseqile.

Ngokuthuthuka Kobuchwepheshe Banamuhla

Intengo Yomshini Wokushisela I-Laser Ayikaze Ithengeke Kanjalo!

2. Amathiphu avamile we-Laser Welding Aluminium

Ukuze Uzuze Imiphumela Emihle Yokushisela, Nawa Amaphuzu Abalulekile:

Ukulungiswa kwendawo

Hlanza njalo indawo ye-aluminium ukuze ususe ama-oxide nezinto ezingcolisayo.

Ukulawula Ukushisa

Gada okokufaka okushisa ngokucophelela ukuze ugweme ukusonteka nokuhlanekezela, ikakhulukazi ezintweni ezizacile.

Isivinini Sokuhamba

Lungisa isivinini sohambo ngokuya ngokujiya kwezinto ukuze ulinganise ukungena nokufaka ukushisa.

Ukulungiswa Kwephoyinti Eligxilile

Gxilisa i-laser kancane ngaphansi kwendawo ukuze ungene kangcono futhi unciphise ukubonakala.

Ukukhetha Phakathi Kwezinhlobo Ezihlukene Zomshini Welding Laser?

Singasiza Ukwenza Isinqumo Esilungile Ngokusekelwe Kuzicelo

3. Ungayithola Kanjani I-Weld Enhle Nge-Aluminium Alloys

Ukuqonda i-Material yakho ku-Half Way lapho

Ukuqonda uchungechunge olujwayelekile lwe-aluminium alloy kubalulekile ekuzuzeni ukushisela okuhle nge-laser welder ephathwa ngesandla ngezizathu ezimbalwa:

Izinto ezibonakalayo

Uchungechunge ngalunye lwe-aluminium alloy lunezici ezihlukile, ezihlanganisa amandla, i-ductility, nendawo yokuncibilika.

Ukwazi lezi zakhiwo kusiza ekukhetheni imingcele yokushisela efanele, njengezilungiselelo zamandla nesivinini sokuhamba, ukuze kuqinisekiswe i-weld eqinile, ephumelelayo.

Izinselele zokushisela

Uchungechunge lwe-alloy oluhlukile lunikeza izinselelo ezithile ngesikhathi sokushisela.

Isibonelo, ama-alloys ochungechunge angu-2000 athambekele ekuqhekekeni, kuyilapho ama-alloys angu-4000 angase ageleze kalula.

Ukuqonda lezi zinselele kuvumela abashiseli ukuthi basebenzise amasu okunciphisa izinkinga, njengokushisa kuqala noma ukulungisa izinto zokugcwalisa.

Ukuhambisana Kwezinto Zokugcwalisa

Ama-alloys e-aluminium ahlukene adinga izinto zokugcwalisa ezihambisanayo ukuze kuqinisekiswe isibopho esiqinile.

Isibonelo, ukusebenzisa intambo yokugcwalisa efanele kunganqanda izinkinga ezifana ne-porosity noma ukuhlangana okunganele.

Ulwazi lochungechunge lwe-alloy lusiza ekukhetheni intambo yokugcwalisa efanele ukuthuthukisa ikhwalithi yokushisela.

Ukukhethwa Kwegesi Yokuvikela

Ukukhethwa kwegesi yokuvikela kungathinta kakhulu ikhwalithi ye-weld.

Uchungechunge lwe-alloy ngalunye lungadinga amagesi athile okuvikela ukuvimbela i-oxidation nokuthuthukisa ukungena.

Ukuqonda ukwakheka kwengxubevange kusiza abashiseli bakhethe igesi yokuvikela engcono kakhulu ukuze bathole imiphumela emihle.

Ukuphathwa Kokushisa

Ama-alloys ahlukene asabela ngendlela ehlukile ekushiseni.

Okunye kungase kudinge ukushisisa kwangaphambili noma ukwelashwa kwe-post-weld ukuze kudambise ingcindezi.

Ukuqonda uchungechunge lwe-alloy kuvumela ama-welders ukuthi alawule okokufaka ukushisa ngokuphumelelayo, ukunciphisa ubungozi bokungqubuzana noma ukuqhekeka.

Ukufaneleka Kohlelo

Ama-alloys athile e-aluminium afaneleka kangcono izinhlelo zokusebenza ezithile, njenge-aerospace noma izimoto.

Ukwazi izici zochungechunge ngalunye kusiza ekukhetheni ingxubevange efanele yomsebenzi, ukuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nezindinganiso zokusebenza nezokuphepha.

Ukusebenza Kwezindleko

Ukusebenzisa i-alloy efanele kanye nemingcele yokushisela kungaholela ezinqubweni zokushisela ezisebenza kahle, ukunciphisa udoti wezinto ezibonakalayo nokusebenza kabusha.

Ukuqonda izakhiwo ze-alloy kunomthelela ekuhleleni nasekusetshenzisweni okungcono, ekugcineni konga isikhathi nezindleko.

Ukuqinisekisa ikhwalithi

Ukuqwashisa ngochungechunge oluhlukile lwe-aluminium kusiza ekusunguleni izinyathelo zokulawula ikhwalithi.

Ama-welders angakwazi ukusebenzisa amasu namazinga athile asekelwe ohlotsheni lwe-alloy, okuholela ekushiseni okungaguquki nokuphezulu.

I-Aluminium yokushisela inzima nge-Traditional Welding

Laser Welding Lula Le nqubo

Ufuna ukwazi okwengeziwe nge-Laser Welding Aluminium?

I-Aluminiyamu yokushisela iyinkohliso kune-Welding Ezinye Izinto.

Ngakho-ke Sabhala Indatshana mayelana nokuthi Ungawathola Kanjani Ama-Welds Amahle nge-Aluminium.

Kusukela kuzilungiselelo kuye kokuthi kanjani.

Ngamavidiyo Nolunye Ulwazi.

Unentshisekelo ku-Laser Welding Ezinye Izinto?

Ingabe ufuna ukuqalisa nge-Laser Welding Fast?

Ingabe ufuna ukuvuselela ulwazi lwakho lwe-Laser Welding?

Lo mhlahlandlela ophelele wereferensi wenzelwe wena nje!

I-High-Capacity & Wattage yezinhlelo zokusebenza zokushisela ezihlukahlukene

Umshini wokushisela we-laser ongu-2000W ubonakala ngosayizi womshini omncane kodwa ikhwalithi yokushisela ekhazimulayo.

Umthombo we-fiber laser ezinzile kanye nekhebula lefayibha exhunyiwe inikeza ukulethwa kwe-laser beam ephephile futhi engaguquki.

Ngamandla aphezulu, i-laser welding keyhole iphelele futhi yenza i-welding joint firmer iqine ngisho nangensimbi ewugqinsi.

Ukuphatheka kokuvumelana nezimo

Ngokubukeka komshini ohlangene futhi omncane, umshini we-laser welder ophathwayo ufakwe isibhamu se-laser esiphathwayo esinyakazayo esingasindi futhi esilungele ukusetshenziswa kwe-multi-laser welding kunoma iyiphi i-engeli nangaphezulu.

Izinhlobo ezihlukahlukene zokuzikhethela ze-laser welder nozzle kanye nezinhlelo zokuphakela izintambo ezizenzakalelayo zenza ukusebenza kwe-laser welding kube lula futhi lokho kube nobungane kwabaqalayo.

I-high-speed laser welding kukhulisa kakhulu ukusebenza kahle kwakho kokukhiqiza kanye nokuphumayo kuyilapho kunika amandla umphumela omuhle kakhulu we-laser welding.

Izinto OKUMELE Uzazi mayelana: Handheld Laser Welding

Uma uyijabulele le vidiyo, kungani ungacabangiubhalisela Isiteshi sethu se-YouTube?

Izicelo Ezihlobene Ongase Uzithande:

Konke Okuthengiwe Kufanele Kwaziswe Kahle

Singasiza Ngolwazi Oluningiliziwe kanye Nokubonisana!

Isikhathi sokuthumela: Dec-20-2024