Ungakhetha Kanjani Izingxube Zegesi Ezingcono Kakhulu Zokushisela I-Laser Yakho?

Izinhlobo, Izinzuzo, kanye nezicelo

Isingeniso:

Izinto Ezibalulekile Okufanele Uzazi Ngaphambi KokuDibela

Ukushisela nge-laser kuyindlela yokushisela enembayo ephezulu esebenzisa ugongolo lwe-laser ukuncibilikisa i-material ye-workpiece bese yakhe i-weld ngemva kokupholisa. Ku-laser welding, igesi idlala indima ebalulekile.

Igesi evikelayo ayithinti nje kuphela ukwakheka kwe-welding seam, ikhwalithi ye-welding seam, ukungena kwe-welding seam, nobubanzi bokungena kodwa futhi ithinta ngokuqondile ikhwalithi nokusebenza kahle kwe-laser welding.

Imaphi amagesi adingekayo ukuze kushiswe i-laser?Lesi sihloko sizobheka kabanziukubaluleka kwamagesi we-laser welding, amagesi asetshenziswayo, nalokho akwenzayo.

Sizophinde sincomethe best laser welding umshiningokwezidingo zakho.

Kungani Kudingeka Igesi Ukuze Welding Laser?

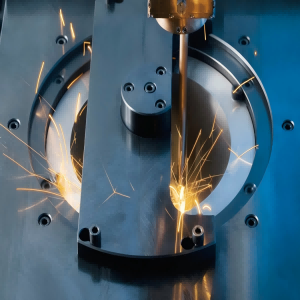

I-Laser Beam Welding

Ngesikhathi senqubo yokushisela i-laser, ugongolo lwe-laser olunamandla amakhulu lugxile endaweni yokushisela ye-workpiece.

Ukubangela ukuncibilika ngokushesha kwezinto ezingaphezulu kwendawo yokusebenza.

Igesi iyadingeka ngesikhathi sokushisela i-laser ukuvikela indawo yokushisela.

Lawula izinga lokushisa, uthuthukise ikhwalithi ye-weld, futhi uvikele isistimu yokubona.

Ukukhetha uhlobo lwegesi olufanele kanye nemingcele yokuhlinzeka kuyizinto ezibalulekile ekuqinisekiseni ukusebenza kahle.

Futhi ezinzile laser welding inqubo kanye nokuthola izinga okusezingeni eliphezulu imiphumela welding.

1. Ukuvikelwa Kwezindawo Zokushisela

Phakathi nenqubo yokushisela i-laser, indawo yokushisela ibonakala endaweni yangaphandle futhi ithinteka kalula umoya-mpilo namanye amagesi emoyeni.

I-oksijeni ibangela ukusabela kwe-oxidation okungase kuholele ekunciphiseni ikhwalithi ye-weld, nokudala ama-pores kanye ne-inclusions. I-weld ingavikelwa ngokuphumelelayo ekungcoleni komoya-mpilo ngokunikeza igesi efanelekile, ngokuvamile igesi engasebenzi njenge-argon, endaweni yokushisela.

2. Ukulawula Ukushisa

Ukukhethwa kwegesi nokunikezwa kungasiza ukulawula izinga lokushisa lendawo yokushisela. Ngokulungisa izinga lokugeleza kanye nohlobo lwegesi, izinga lokupholisa lendawo yokushisela lingathinteka. Lokhu kubalulekile ukulawula indawo ethinteke ukushisa (HAZ) ngesikhathi sokushisela nokunciphisa ukuhlanekezela okushisayo.

3. Ikhwalithi Ye-Weld Ethuthukisiwe

Amanye amagesi asizayo, njenge-oxygen noma i-nitrogen, angathuthukisa ikhwalithi nokusebenza kwama-welds. Isibonelo, ukwengeza umoya-mpilo kungathuthukisa ukungena kwe-weld futhi kwandise isivinini sokushisela, kuyilapho kuthinta ukuma nokujula kwe-weld.

4. Ukupholisa Igesi

Ku-laser welding, indawo yokushisela ivame ukuthinteka ngamazinga okushisa aphezulu. Ukusebenzisa isistimu yokupholisa igesi kungasiza ukulawula izinga lokushisa lendawo yokushisela nokuvimbela ukushisa ngokweqile. Lokhu kubalulekile ukuze kuncishiswe ukucindezeleka okushisayo endaweni yokushisela futhi kuthuthukiswe ikhwalithi yokushisela.

I-Automated Laser Beam Welding

5. Igesi Ukuvikelwa Of Optical Systems

I-laser beam igxile endaweni yokushisela ngokusebenzisa uhlelo lwe-optical.

Ngesikhathi se-soldering, izinto ezincibilikisiwe nama-aerosols akhiqizwayo angase angcolise izingxenye ze-optical.

Ngokungenisa amagesi endaweni yokushisela, ingozi yokungcola iyancipha futhi impilo yesistimu ye-optical yandiswa.

Imaphi Amagesi Asetshenziswa Ku-Laser Welding?

Ku-laser welding, igesi ingahlukanisa umoya epuleti lokushisela futhi iwuvimbele ukuthi usabele emoyeni. Ngale ndlela, i-welding surface ye-metal plate izoba mhlophe futhi ibe yinhle kakhulu. Ukusebenzisa igesi kuvikela namalensi othulini olushiselayo. Ngokuvamile, amagesi alandelayo asetshenziswa:

1. Igesi Evikelayo:

Amagesi okuvikela, ngezinye izikhathi abizwa ngokuthi "amagesi angenayo," adlala indima ebalulekile enqubweni yokushisela i-laser. Izinqubo zokushisela i-laser zivame ukusebenzisa amagesi angenayo ukuvikela i-weld pool. Amagesi avikelayo asetshenziswa kakhulu ku-laser welding ikakhulukazi afaka i-argon ne-neon. Izakhiwo zabo ezingokomzimba namakhemikhali zihlukile, ngakho-ke imiphumela yazo ku-weld nayo ihlukile.

Igesi Evikelayo:I-Argon

I-Argon ingenye yamagesi angenayo asetshenziswa kakhulu.

Inezinga eliphezulu le-ionization ngaphansi kwesenzo se-laser, esingenakukwazi ukulawula ukwakheka kwamafu e-plasma, okuzoba nomthelela othile ekusetshenzisweni ngempumelelo kwama-lasers.

Imvelo ye-inert ye-argon igcina ingaphandle kwenqubo ye-soldering, kuyilapho iphinde ilahle ukushisa kahle, isiza ukulawula izinga lokushisa endaweni ye-soldering.

Igesi Evikelayo:I-Neon

I-Neon ivame ukusetshenziswa njengegesi ye-inert, efana ne-argon, futhi isetshenziselwa ukuvikela indawo yokushisela emoyeni kanye nezinye izinto ezingcolile endaweni yangaphandle.

Kubalulekile ukuqaphela ukuthi i-neon ayifanele zonke izinhlelo zokusebenza ze-laser welding.

Isetshenziselwa ikakhulukazi imisebenzi ethile ekhethekile yokushisela, njengokushisela izinto eziwugqinsi noma lapho kudingeka imithungo ejulile yokushisela.

2. I-Axiliary Gas:

Ngesikhathi senqubo ye-laser welding, ngaphezu kwegesi eyisivikelo eyinhloko, amagesi asizayo angasetshenziswa futhi ukuthuthukisa ukusebenza kwe-welding kanye nekhwalithi. Okulandelayo amanye amagesi asizayo ajwayelekile asetshenziswa ekushiseleni nge-laser.

I-Axiliary Gas:Umoya-mpilo

Umoya-mpilo uvame ukusetshenziswa njengegesi yokusiza futhi ungasetshenziswa ukukhulisa ukushisa nokujula kwe-weld ngesikhathi sokushisela.

Ukwengeza umoya-mpilo kungakhuphula isivinini sokushisela nokungena, kodwa kudinga ukulawulwa ngokucophelela ukuze kugwenywe umoya-mpilo oweqile obangela izinkinga ze-oxidation.

I-Axiliary Gas:Ingxube ye-Hydrogen/I-Hydrogen

I-Hydrogen ithuthukisa ikhwalithi yama-welds futhi inciphisa ukwakheka kwe-porosity.

Izingxube ze-argon ne-hydrogen zisetshenziswa kwezinye izinhlelo zokusebenza ezikhethekile, njengokushisela insimbi engagqwali. Okuqukethwe kwe-hydrogen kule ngxube kuvame ukusuka ku-2% kuye ku-15%.

Igesi Evikelayo:I-nitrogen

I-nitrogen nayo ivame ukusetshenziswa njengegesi elisizayo ku-laser welding.

Amandla e-ionization we-nitrogen aphakathi, aphezulu kune-argon futhi aphansi kune-hydrogen.

Idigri ye-ionization ngokuvamile ingaphansi kwesenzo se-laser. Kunganciphisa kangcono ukwakheka kwamafu e-plasma, kunikeze izinga eliphezulu lokushisela nokubukeka, futhi kunciphise umthelela we-oxygen kuma-welds.

I-nitrogen ingasetshenziswa futhi ukulawula izinga lokushisa lendawo yokushisela nokunciphisa ukwakheka kwamabhamuza nama-pores.

Igesi Evikelayo:I-Helium

I-Helium ivamise ukusetshenziselwa ukushisela i-laser yamandla aphezulu ngenxa yokuthi ine-conductivity ephansi eshisayo futhi ayinayo i-ionized kalula, ivumela i-laser ukuthi idlule kahle namandla e-beam ukuthi afinyelele endaweni yokusebenza ngaphandle kwezithiyo.

Ivumela ukushisela amandla aphezulu. I-Helium ingasetshenziswa futhi ukuthuthukisa ikhwalithi yokushisela nokulawula izinga lokushisa lokushisela. Leli igesi elisebenza kahle kakhulu elivikelayo elisetshenziswa ekushiseleni nge-laser, kodwa libiza kakhulu.

3. Igesi Yokupholisa:

Igesi yokupholisa ivame ukusetshenziswa ngesikhathi sokushiswa kwe-laser ukulawula izinga lokushisa lendawo yokushisela, ukuvimbela ukushisa ngokweqile, nokugcina ikhwalithi yokushisela. Okulandelayo ngamanye amagesi okupholisa asetshenziswa kakhulu:

Igesi Yokupholisa/ Emaphakathi:Amanzi

Amanzi ayindlela yokupholisa evamile evame ukusetshenziselwa ukupholisa amajeneretha e-laser kanye nezinhlelo zokubona nge-laser welding.

Amasistimu okupholisa amanzi angasiza ukugcina izinga lokushisa elizinzile lejeneretha ye-laser kanye nezingxenye ze-optical ukuqinisekisa ukuzinza nokusebenza kwe-laser beam.

Igesi Yokupholisa/ Emaphakathi:Amagesi ase-Atmospheric

Kwezinye izinqubo zokushisela nge-laser, amagesi asemkhathini angasetshenziselwa ukupholisa.

Isibonelo, kusistimu ye-optical ye-laser generator, igesi ye-atmosphere ezungezile inganikeza umphumela wokupholisa.

Igesi Yokupholisa/ Emaphakathi:Amagesi Angasebenzi

Amagesi angasebenzi njenge-argon ne-nitrogen angasetshenziswa njengamagesi okupholisa.

Zine-conductivity ephansi yokushisa futhi zingasetshenziswa ukulawula izinga lokushisa lendawo yokushisela nokunciphisa indawo ethintekile ukushisa (HAZ).

Igesi Yokupholisa/ Emaphakathi:I-nitrogen ye-Liquid

I-liquid nitrogen iyindawo yokupholisa enezinga lokushisa eliphansi kakhulu engasetshenziselwa ukushisela i-laser enamandla kakhulu.

Inikeza umphumela wokupholisa ophumelelayo kakhulu futhi iqinisekisa ukulawulwa kwezinga lokushisa endaweni yokushisela.

4. Igesi Elixutshiwe:

Izingxube zegesi zivame ukusetshenziswa ekushiseleni ukuze kwandiswe izici ezihlukahlukene zenqubo, njengesivinini sokushisela, ukujula kokungena, nokuzinza kwe-arc. Kunezinhlobo ezimbili eziyinhloko zezingxube zegesi: izingxube kanambambili kanye ne-ternary.

Izingxube zegesi kanambambili:I-Argon + Oxygen

Ukwengeza inani elincane le-oksijini ku-argon kuthuthukisa ukuzinza kwe-arc, kuhlanza i-weld pool, futhi kwandisa isivinini sokushisela. Le ngxube ijwayele ukusetshenziselwa ukushisela i-carbon steel, i-low-alloy steel, nensimbi engagqwali.

Izingxube zegesi kanambambili:I-Argon + I-Carbon Dioxide

Ukwengezwa kwe-CO₂ ku-argon kukhulisa amandla okushisela kanye nokumelana nokugqwala ngenkathi kunciphisa isipatha. Le ngxube ivame ukusetshenziselwa ukushisela i-carbon steel nensimbi engagqwali.

Izingxube zegesi kanambambili:I-Argon + Hydrogen

I-Hydrogen inyusa izinga lokushisa kwe-arc, ithuthukisa isivinini sokushisela, futhi yehlisa ukukhubazeka kokushisela. Iwusizo ikakhulukazi ekushiseleni ama-alloys asekelwe ku-nickel kanye nensimbi engagqwali.

Izingxube ze-Ternary Gas:I-Argon + I-Oxygen + I-Carbon Dioxide

Le ngxube ihlanganisa izinzuzo zazo zombili izingxube ze-argon-oksijeni ne-argon-CO₂. Yehlisa i-spatter, ithuthukise i-weld pool fluidity, futhi ithuthukise ikhwalithi yokushisela. Isetshenziswa kabanzi ukushisela ugqinsi oluhlukahlukene lwe-carbon steel, insimbi ene-alloy ephansi, nensimbi engagqwali.

Izingxube ze-Ternary Gas:I-Argon + Helium + I-Carbon Dioxide

Le ngxube isiza ukuthuthukisa ukuzinza kwe-arc, ikhuphule izinga lokushisa le-weld pool, futhi ithuthukise isivinini sokushisela. Isetshenziselwa ukushisela i-arc yesifunda esifushane kanye nezinhlelo zokushisela ezisindayo, enikeza ukulawula okungcono kwe-oxidation.

Ukukhetha Igesi Ezinhlelweni Ezihlukene

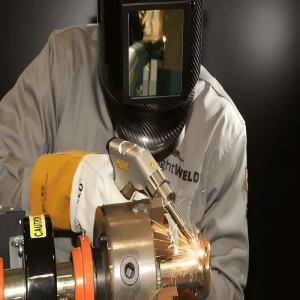

I-Handheld Laser Welding

Ekusetshenzisweni okuhlukahlukene kwe-laser welding, ukukhetha igesi efanelekile kubalulekile, ngoba inhlanganisela yegesi ehlukene ingakhiqiza ikhwalithi ehlukene yokushisela, isivinini, nokusebenza kahle. Nazi ezinye iziqondiso zokukusiza ukuthi ukhethe igesi elungile yohlelo lwakho lokusebenza oluthile:

Uhlobo Lwezinto Zokushisela:

Insimbi engagqwalingokuvamile isebenzisaI-Argon noma i-Argon/Ingxube ye-Hydrogen.

I-Aluminium ne-Aluminium Alloysngokuvamile sebenzisaI-Argon ehlanzekile.

I-Titanium Alloysngokuvamile sebenzisaI-nitrogen.

Izinsimbi Zekhabhoni Ephakemengokuvamile sebenzisaI-oksijeni njengeGesi Elisizayo.

Isivinini sokushisela kanye nokungena:

Uma isivinini se-welding esiphezulu noma ukungena okujulile kwe-welding kuyadingeka, inhlanganisela yegesi ingalungiswa. Ukwengeza umoya-mpilo ngokuvamile kuthuthukisa isivinini nokungena, kodwa kudinga ukulawulwa ngokucophelela ukuze kugwenywe izinkinga ze-oxidation.

Ukulawulwa Kwendawo Ethinteke Ukushisa (HAZ):

Ngokuya ngezinto ezihlanzwayo, imfucuza eyingozi edinga izinqubo ezikhethekile zokuphatha ingase yenziwe ngesikhathi sokuhlanza. Lokhu kungengeza ezindlekweni eziphelele zenqubo yokuhlanza i-laser.

Ikhwalithi ye-Weld:

Ezinye izinhlanganisela zegesi zingathuthukisa ikhwalithi nokubukeka kwama-welds. Isibonelo, i-nitrogen inganikeza ukubukeka okungcono kanye nekhwalithi ephezulu.

Ukulawulwa Kwezimbotshana Nebhamuza:

Kuzinhlelo zokusebenza ezidinga ama-welds aphezulu kakhulu, ukunakwa okukhethekile kufanele kukhokhwe ekwakhiweni kwama-pores nama-bubbles. Ukukhetha kahle igesi kunganciphisa ingozi yalezi zinkinga.

Izisetshenziswa Nezindleko:

Ukukhethwa kwegesi nakho kuthonywa uhlobo lwemishini nezindleko. Amanye amagesi angase adinge amasistimu okuhlinzeka akhethekile noma izindleko eziphakeme.

Ngezicelo ezithile, kunconywa ukuthi usebenze nonjiniyela wokushisela noma umkhiqizi wemishini yokushisela i-laser ukuze uthole izeluleko zochwepheshe kanye nokwandisa inqubo yokushisela.

Okunye ukuhlola nokuthuthukisa kuvame ukudingeka ngaphambi kokuthi kukhethwe inhlanganisela yokugcina yegesi.

Ngokuya ngesicelo esithile, inhlanganisela yegesi ehlukene kanye nemingcele ingazanywa ukuthola izimo zokushisela ezilungile.

Izinto Odinga Ukuzazi Mayelana: Handheld Laser Welding

Kunconyiwe Laser Welding Machine

Ukuze uthuthukise imisebenzi yakho yensimbi neyokucubungula impahla, ukukhetha okokusebenza okufanele kubalulekile. I-MimoWork Laser incoma i-I-Handheld Laser Welding Machineukuze kuhlanganiswe insimbi enembile futhi ephumelelayo.

I-High-Capacity & Wattage yezinhlelo zokusebenza zokushisela ezihlukahlukene

Umshini wokushisela we-laser ongu-2000W ubonakala ngosayizi womshini omncane kodwa ikhwalithi yokushisela ekhazimulayo.

Umthombo we-fiber laser ezinzile kanye nekhebula lefayibha exhunyiwe inikeza ukulethwa kwe-laser beam ephephile futhi engaguquki.

Ngamandla aphezulu, i-laser welding keyhole iphelele futhi yenza i-welding joint firmer iqine ngisho nangensimbi ewugqinsi.

Ngokubukeka komshini ohlangene futhi omncane, umshini we-laser welder ophathwayo ufakwe isibhamu se-laser esiphathwayo esinyakazayo esingasindi futhi esilungele ukusetshenziswa kwe-multi-laser welding kunoma iyiphi i-engeli nangaphezulu.

Izinhlobo ezihlukahlukene zokuzikhethela ze-laser welder nozzle kanye nezinhlelo zokuphakela izintambo ezizenzakalelayo zenza ukusebenza kwe-laser welding kube lula futhi lokho kube nobungane kwabaqalayo.

I-high-speed laser welding kukhulisa kakhulu ukusebenza kahle kwakho kokukhiqiza kanye nokuphumayo kuyilapho kunika amandla umphumela omuhle kakhulu we-laser welding.

Fingqa

Ngamafuphi, i-laser welding idinga ukusebenzisa igesi ukuvikela izindawo zokushisela, ukulawula izinga lokushisa, ukuthuthukisa ikhwalithi yokushisela, nokuvikela amasistimu okukhanya. Ukukhetha izinhlobo ezifanele zegesi kanye nemingcele yokuhlinzeka kuyisici esibalulekile ekuqinisekiseni inqubo ye-laser welding ephumelelayo futhi ezinzile kanye nokuthola imiphumela yekhwalithi ephezulu yokushisela. Izinto ezisetshenziswayo ezahlukahlukene kanye nezicelo zingadinga izinhlobo ezahlukahlukene kanye nezilinganiso ezixubile ukuze kuhlangatshezwane nezidingo ezithile zokushisela.

Xhumana nathi namuhlaukuze ufunde kabanzi mayelana nabasiki bethu be-laser nokuthi bangayithuthukisa kanjani inqubo yakho yokukhiqiza yokusika.

Izixhumanisi Ezihlobene

Noma yimiphi Imibono Ngemishini Yokushisela I-Laser?

Isikhathi sokuthumela: Jan-13-2025