I-Aluminium yokuhlanza i-laser: kanjani

I-aluminium ne-aluminium alloys kukhonaesetshenziswa kakhulu kwezokuthutha ngololiwengenxa yamandla akhethekile aphezulu kanye nokumelana nokugqwala.

Ingaphezulu le-aluminium ingxubevange isabela kalula emoyeni futhi yakhe ifilimu yemvelo ye-oxide.

Kulesi sihloko, sizokutshelakonke odinga ukukwazimayelana ne-laser-yokuhlanza i-aluminium.

Kubandakanya ukuthi kungani kufanele ukhethe ukuhlanza nge-laser ye-aluminium, indlela yokuhlanza i-aluminiumi-pulsed laser yokuhlanza, kanye nezinzuzo ze-laser yokuhlanza i-aluminium.

Uhlu Lokuqukethwe:

Ingabe Ukuhlanza I-Laser Kusebenza Ku-Aluminium?

Ngokujwayelekile Ukusebenzisa Umshini Wokuhlanza I-Laser

Ukuhlanza i-laser kuyisisombululo esisebenzayo sokuhlanza izindawo ze-aluminium ezinhlelweni zezimboni.

Inikezaizinzuzo eziningana phezu izindlela zokuhlanza bendabuko.

Njengokuhlanza amakhemikhali, ukupholisha ngomshini, ukuhlanzwa kwe-electrolytic, nokuhlanza nge-ultrasonic.

Azikho Izinsalela Zamakhemikhali:

Ukuhlanza i-laser kuyinqubo eyomile, engathinteki, okusho ukuthi azikho izinsalela zamakhemikhali ezisele.

Lokhu kubalulekile ezimbonini zikaloliwe nezezindiza.

I-Surface Finish Ethuthukisiwe:

Ukuhlanzwa nge-laser kungathuthukisa ukuphela kwe-aluminium ngokususa ukungapheleli kwendawo, i-oxidation, nezinye izinto ezingafuneki.

Lokhu kubangela ukubukeka okuhlanzekile, okufanayo.

Ubungane Bemvelo:

Ukuhlanza i-laser kuyinkqubo enobungani bemvelo, njengoba kungadingi ukusetshenziswa kwamakhemikhali ayingozi noma ama-solvents, okungaba yingozi emvelweni.

Ukunamathela Okuthuthukisiwe:

Indawo ehlanzekile, engangcolisi etholwe ngokuhlanzwa nge-laser ingathuthukisa ukunamathela kwama-coatings, amapende, noma okunye ukwelapha okungaphezulu okufakwe ku-aluminium.

Ukulimala Nokungenabungozi:

Ukuhlanza i-laser kuvumela ukususwa okuhloswe kakhulu nokunembayo kwezinto ezingafunwa ngaphandle kokulimaza indawo engaphansi ye-aluminium.

I-laser ingalawulwa ngokunembile ukuze kukhishwe kuphela ukungcola okufunayo.

Ukuhlukahluka:

Ukuhlanza i-laser kungasetshenziswa ezinhlobonhlobo zezingxenye nezingxenye ze-aluminium.

Kusukela ezingxenyeni ezincane eziyinkimbinkimbi kuya ezakhiweni ezinkulu, okwenza kube isisombululo sokuhlanza esisebenza ngezindlela eziningi.

Ungakwazi yini i-Laser ku-Aluminium?

Yebo, Ungasebenzisa Ama-Lasers ku-Aluminium.

Ubuchwepheshe be-laser busebenza kahle ukusika, ukuqopha, nokuhlanza izindawo ze-aluminium. Nazi ezinye izinhlelo zokusebenza ezijwayelekile:

Ukusika i-Laser nokuqoshwa kwe-Laser:

I-laser yokuhlanza i-aluminium iqinisekisa ukwelashwa okuqondile kwendawo kanye nokuqedwa okushelelayo uma kuqhathaniswa nezindlela zokuhlanza zendabuko. Isusa kahle ukugqwala, upende, noma izinsalela kuyilapho ilondoloza ukuthungwa kwasekuqaleni kwensimbi. Inqubo ilungele ukubuyisela okuningiliziwe, okuqinisekisa okuhlala isikhathi eside, imiphumela yekhwalithi ephezulu ethuthukisa kokubili ukubukeka nokuqina.

Okokuhlanza i-Laser:

Isusa kahle ukungcola okufana nokugqwala nopende ngaphandle kokulimaza i-aluminium, ngaphandle kwamakhemikhali adingekayo.

Ukusebenza komshini wokuhlanza nge-laser kungahluka kuye ngokuqina nesimo sendawo ye-aluminium. Izinhlobo ezahlukene ze-laser, njenge-CO2 ne-fiber, zenzelwe ukuhlanza nokubuyisela imisebenzi ethile. Umshini wokuhlanza we-laser unikeza ukuguquguquka kokubili ukugcinwa kwezimboni kanye nokukhiqiza ngokunemba, okwenza kube yisixazululo esithembekile sezinhlelo zokusebenza ezihlukahlukene ze-aluminium.

Isiphi Isixazululo Esingcono Kakhulu Sokuhlanza I-Aluminium?

Okokuhlanza Kwezimboni noma Okunzima, Ukuhlanzwa kweLaser kuyindlela okufanele uhambe ngayo.

I-Handheld Laser Cleaning Machines ingasusa ngempumelelo ukungcola ngaphandle kokulimaza i-aluminium. Ngaphezu kwezinzuzo ezishiwo ngenhla, ukuhlanza nge-laser nakhoinikeza izinzuzo eziyingqayizivele zezinhlelo zokusebenza zokushisela:

Ikhwalithi Ye-Weld Ethuthukisiwe Kakhulu:

Ukuhlanza nge-laser kususa ukungcola okungaphezulu, ama-oxide, nokungcola okungaba nomthelela omubi kwikhwalithi namandla okushisela.

Ngokuhlinzeka ngendawo ehlanzekile, engenakho ukungcola, ukuhlanzwa nge-laser kusiza ukuqinisekisa ukuhlangana okungcono, amajoyinti okushisela aqinile, kanye nokunciphisa ingozi yokukhubazeka.

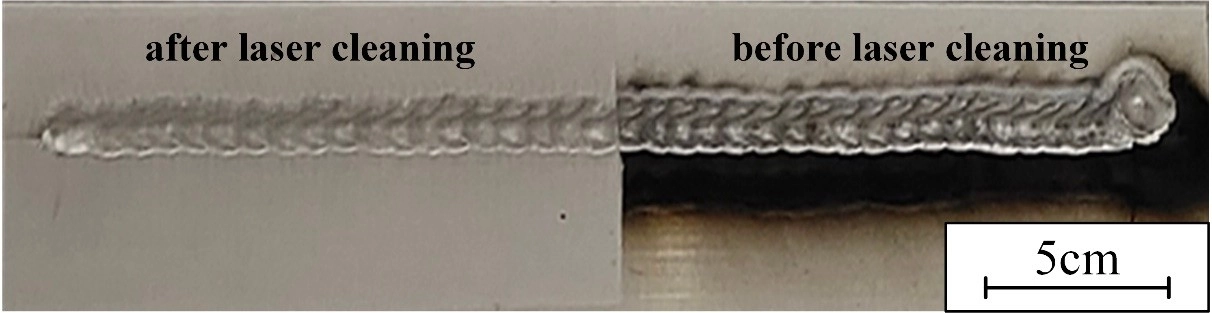

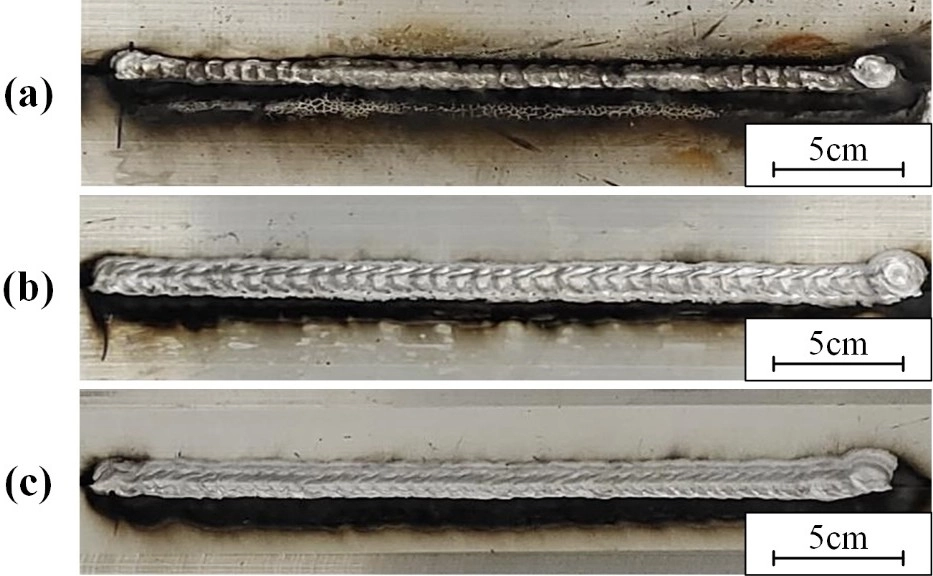

Ukwakheka kokushisela ngaphambi nangemuva kokuhlanza ngomlotha omnyama ku-aluminum nge-laser.

Ukuvumelana Kwe-Weld Okukhulisiwe:

Ukuhlanzwa kwe-laser kunikeza ukulungiswa okungaguquguquki, okuphindaphindwayo kwendawo, okuholela kukhwalithi yokushisela engaguquguquki kanye nezakhiwo kuwo wonke ama-welds amaningi.

Lokhu kuvumelana kubalulekile ezinqubweni zokukhiqiza, ukulawulwa kwekhwalithi, kanye nokuqinisekisa ukusebenza okuthembekile komhlangano oshiselwe.

I-Weld Porosity eyehlisiwe:

Ukuhlanza i-laser kususa ngempumelelo ukungcola okungaphezulu nama-oxide angaholela ekwakhekeni kwe-weld porosity.

Ukunciphisa i-weld porosity kuthuthukisa izakhiwo zemishini kanye nobuqotho bejoyinti le-weld.

Ukushisela Okuthuthukisiwe:

Indawo ehlanzekile eshiywe ukuhlanzwa nge-laser ingathuthukisa ukushisela kwe-aluminium, kwenze kube lula ukuzuza ukushisela okunomsindo, okunganasici.

Lokhu kuzuzisa kakhulu lapho ushisela izinto ze-aluminium ezacile noma usebenza ngama-alloys e-aluminium ayinselele.

Ukubukeka Kwe-Weld Okuthuthukisiwe:

Indawo ehlanzekile, neyunifomu eshiywe ukuhlanzwa nge-laser iphumela ekubukekeni kwe-weld ebukeka kahle.

Lokhu kubaluleke kakhulu ezinhlelweni lapho i-weld ibonakala khona noma idinga ukuhlangabezana nezidingo eziqinile zobuhle.

Uma ungaphansi kuka-aisicelo sokusebenzisa ekhaya, ezinye Izixazululo Zamanzi Ezinsipho noma Zezentengiselwano Ze-Aluminium Cleaner nazo zingase zisebenze kahle, khumbula Ukugwema amaphedi abrasive noma amakhemikhali anokhahlo akwazi ukuklwebha noma ukugqwalisa i-aluminium.Hlola njalo noma yisiphi isisombululo sokuhlanza endaweni encane, engacacile kuqala.

I-Aluminium yokuhlanza i-Laser ingaba Lucky

Singasiza!

Yiziphi Izinkinga Zokuhlanza I-Laser?

Izindleko Zokuqala Nokubhekana Nezingubo Eziminyene Ezengeziwe, lokho kumayelana nakho ngempela.

Izindleko zangaphambili zokuthenga umshini wokuhlanza laser ophethwe ngesandla zingabaluleka (Uma kuqhathaniswa Nezindlela Zokuhlanza Zendabuko). Nokho, kusukela Laser CleaningIDINGA ugesi KUPHELA, I-Operational Cost ishibhile.

Ukuhlanza i-laser kungase kube nzima nezingqimba EZIKUKHULU KAKHULU zokugqwala. Nokho,okukhipha amandla anelefuthiabahlanza amagagasi e-laser aqhubekayokufanele ixazulule le nkinga.

Ngokuhlanza Ngaphambi Kwe-welding ku-Aluminium, I-Laser Ilingana Nezicathulo Ngokuphelele

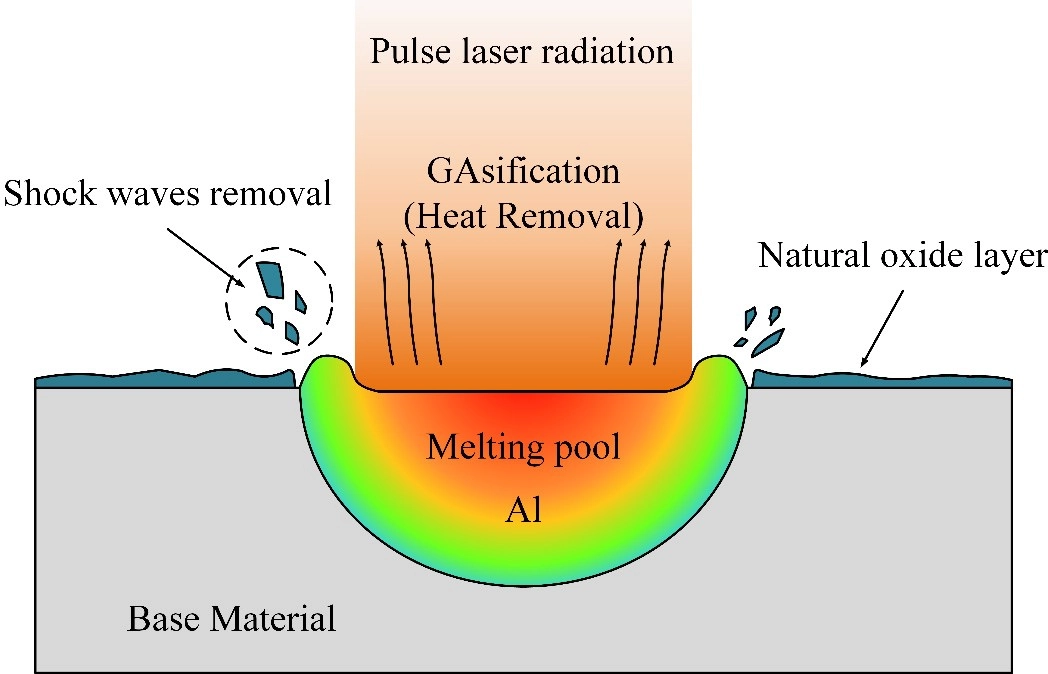

Ukuhlanza i-laser kuyindlela enamandla yokulungiselela indawo ngaphambi kokushisela,ikakhulukazi lapho ubhekene nokungcola okufana nokugqwala, uwoyela, namafutha.

Lokhu kungcola kungonakalisa kakhulu ikhwalithi yokushisela, okuholela ezindabeni ezinjengokuqina kanye nezakhiwo ezingezinhle zemishini.

Ukungcola okungaphezulu kwe-aluminium kungavimbela ukuhlangana okufanele phakathi kwesisekelo sensimbi nezinto zokugcwalisa ngesikhathi sokushisela.

Lokhu kungase kubangele izici ezifana porosity, imifantu, kanye inclusions, okungase kakhulu buthaka ukushisela.

Ukususa lezi zinto ezingcolile kubalulekileukuqinisekisa ikhwalithi ephezulu, ukushisela okuqinile.

Njengoba ucwaningo luye lwabonisa, ukuhlanza laseringasusa ngempumelelo ukungcola futhi icindezele ama-weld porosities ezindaweni ezingaphezulu kwe-aluminium ngamafutha namanzi.

Ucwaningo luthole ukuthi i-porosity yayinjalokuncishisiwekusuka ku-28.672% naku-2.702%ukuya ku-0.091%, ngokulandelana,ngemuva kokuhlanza i-laser.

Ukwengeza, umlotha omnyama ozungeze umthungo we-weld ungasuswa ngempumelelo ngokuhlanzwa kwe-laser post-weld, futhi lokhu kuthuthukisa kancane ukunwetshwa kwe-weld.

Ukwakheka kokushisela kusampula: (a) uwoyela; (b) amanzi; (c) ukuhlanza nge-laser.

Yini okungafanele Uhlanze ngayo i-Aluminium?

Ukucekela phansi i-Aluminium Empeleni Kulula kunalokho ocabanga ngakho

Ingabe ufuna ukucekela phansi i-Aluminium yakho ngokuhlanza? Sebenzisa lokhu:

Ama-Abrasive Cleanersukunwaya futhi buthuntu ubuso be-aluminium.

Izixazululo ze-Acidic noma ezine-Alkalineukugqwala nokukhipha umbala we-aluminium.

Ibhulashikubangela ukugoba nokushintsha kombala ezindaweni ezingaphezulu kwe-aluminium.

Uvolo Wensimbi noma Amaphedi Wokukhucululashiya imihuzuko futhi ubangele ukugqwala.

Amawasha anengcindezi ephezululimaza izigxivizo nokufakwa, futhi kungenzeka zingahlanzeki kahle izindawo ezithambile.

I-Harsh Solventsimichilo yezingubo zokuzivikela futhi ilimaze indawo engaphezulu.

Izihlanzi zikahhaviningokuvamile ziyi-caustic futhi zingalimaza izindawo ze-aluminium.

Ufuna Ukuhlanza Aluminium theKWESOKUDLAIndlela? Zama i-Laser Cleaning

I-Aluminium ineizici eziyingqayiziveleokwenza ukushisela nokuyihlanza kube nzima kakhulu uma kuqhathaniswa nezinye izinsimbi njengensimbi engagqwali.

I-Aluminium iyinto ekhanyayo kakhulu, engenza kube inselele ukumunca amandla e-laser ngesikhathi sokuhlanza.

Ukwengeza, ungqimba lwe-oxide olwakha phezu kwe-aluminium kungaba nzima ukususa, kuqhubekisele phambili inqubo yokuhlanza.

Ngokweizilungiselelo ezingcono kakhulunge-laser yokuhlanza i-aluminium.

Kubalulekile ukuqaphela ukuthi izilungiselelo ezisetshenziswa ku-iphepha elikhonjiwe(150W, 100Hz, kanye nesivinini sokuhlanza esingu-0.8m/min).

Athize ku-6005A-T6 aluminium alloybafunda kanye nemishini ababeyisebenzisa.

Lezi zilungiselelo zingasebenzanjengendawo eyinkomba, kodwa kungase kudingeke ukuthi zilungiswe kuhlelo lwakho lokusebenza oluthile namathuluzi.

Kafushane, ukuhlanza nge-laser kuyindlela ephumelelayo yokulungisa izindawo ze-aluminium ngaphambi kokushisela.

Njengoba ingasusa ukungcola futhi ithuthukise ikhwalithi yokushisela.

Nokho, izici eziyingqayizivele ze-aluminium zidinga ukucatshangelwa ngokucophelela.

Lapho unquma izilungiselelo ezilungile zokuhlanza i-laser zohlelo lwakho lokusebenza oluthile.

Ulwazi olunikezwe kulesi sihloko lusekelweidatha etholakala esidlangalaleni nocwaningo.

Angifuni ubunikazi banoma iyiphi idatha noma ucwaningo olusetshenzisiwe.

Lokhu kungenxa yezinjongo zolwazi kuphela.

I-Pulsed Laser yokuhlanza i-Aluminium

Ingabe ufuna i-Pulse Laser Cleaning Aluminium? Ungabheki Okunye!

I-Pulsed Laser Cleaner

Okwe-Aluminium Yokuhlanza I-Laser (100W, 200W, 300W, 500W)

Bopha amandla obuchwepheshe belaser ye-pulsed fiber ukuze uthathe umdlalo wakho wokuhlanza uye phezulu.

Izipesheli zethu zokuhlanza i-laser ezisezingeni eliphezuluukunemba nokusebenza kahle okungenakuqhathaniswa.

Ngaphandle kokuyekethisa ubuqothoezindaweni zakho ezithambile.

I-pulsed laser okukhiphayo iqondise ukungcola ngokunemba kwe-laser-sharp.

Ukuqinisekisa aukuphela okungenabala ngaphandle kokulimala okuhlobene nokushisa.

Ukukhishwa kwe-laser okungaqhubeki namandla aphezulu aphezulu kwenza lokhu okuhlanzekile kube ukonga amandla kwangempela.

Ukulungiselela izinsiza zakhoukusebenza kahle kwezindleko.

Ukusuka ekukhipheni ukugqwala nokukhumula upende kuye ekuqedeni i-oxide nokususwa kokungcola.

Jabulelaukuzinza kwe-premium nokuthembekangobuchwepheshe bethu besimanje be-fiber laser,Idizayinelwe ukumelana nokuhlolwa kwesikhathi.

Yenza inqubo yokuhlanza ihambisane nezidingo zakho ezithile ngezilungiselelo ze-laser eziguquguqukayo,Ukuqinisekisa umphumela ophelele ngaso sonke isikhathi.

Izwa iinkululeko yokuqondisa nokulungisa izindawo zokuhlanza nama-engelingedizayini yethu esebenziseka kalula, e-ergonomic.

Ividiyo Ehlobene: Kungani Ukuhlanza I-Laser Kungcono Kakhulu

Lapho uhlola izindlela eziphezulu zokuhlanza izimboni ze-sandblasting, ukuhlanza iqhwa elomile, ukuhlanza amakhemikhali, nokuhlanza nge-laser.

Kuyacaca ukuthi indlela ngayinye inikezaisethi eyingqayizivele yezinzuzo nokuhwebelana.

Ukulinganisa okuphelele phakathi kwezici ezihlukahlukene kubonisa ukuthi:

Ukuhlanza i-laserugqama njengoisixazululo esiguquguqukayo, esingabizi kakhulu, nesisebenziseka kalula.

Uma uyijabulele le vidiyo, kungani ungacabangiubhalisela Isiteshi sethu se-YouTube?

Izincomo zomshini ze-Laser Cleaning Aluminium

FAQS

Umshini wokuhlanza we-laser usebenzisa imishayo ye-laser egxilile ukuze ususe ukugqwala, upende, kanye ne-oxidation ezindaweni zensimbi njenge-aluminium ngaphandle kokulimaza isisekelo.

Yebo, ukuhlanza nge-laser kusebenza ngempumelelo kuma-alloys amaningi e-aluminium. Izilungiselelo zingalungiswa ukuze zifane nobukhulu bendawo nesimo ukuze kube nemiphumela emihle.

Cha, lapho kulungiselelwe kahle, ukuhlanzwa nge-laser kugcina ukuthungwa nokuphela kwe-aluminium ngenkathi kushiya indawo ehlanzekile, epholishiwe.

Ngokungafani ne-sandblasting noma amakhemikhali, ukuhlanzwa nge-laser akukhiqizi, ku-eco-friendly, futhi kudinga ukulungiswa okuncane, okukwenza kuphephe futhi kungabizi kakhulu.

Ukuhlanza i-Laser kuyikusasa labakhi kanye nabanikazi bamaworkshop

Futhi Ikusasa Liqala Ngawe!

Kugcine ukubuyekezwa: Okthoba 9, 2025

Isikhathi sokuthumela: Aug-13-2024