I-Laser Cutting Paper:

Ukukhanyisa Ukudala Okungenamkhawulo Nokunemba

▶ Isingeniso:

Ukusika i-Laser kwephepha kuthatha ubuhlakani nokunemba ezindaweni eziphakeme. Ngobuchwepheshe be-laser, imiklamo eyinkimbinkimbi, amaphethini ayinkimbinkimbi, kanye nezimo ezibucayi zingasikwa kalula ngokunemba okungenakuqhathaniswa. Noma ngabe okobuciko, izimemo, ukupakisha, noma ukuhlobisa, ukusika nge-laser kuvula amathuba angapheli. Valelisa ekusikeni okwenziwa ngesandla okukhandlekayo futhi wamukele imiphetho ehlanzekile, ethokomele ngokusika i-laser. Izwa ukuguquguquka nokusebenza kahle kwale nqubo ephambili, okwenza amaphrojekthi akho ephepha aphile ngokunemba okumangalisayo nemininingwane eyinkimbinkimbi. Phakamisa ubuciko bakho bephepha ngokunemba kokusika kwe-laser.

Izimiso Nezinzuzo Eziyinhloko Zephepha Lokusika I-Laser:

▶ I-Laser Paper Cutting:

Uma kuqhathaniswa nezindlela zendabuko zezandla, ukusika kwe-laser kunikeza isivinini esikhulu, ukunciphisa izindleko zabasebenzi, kuqeda isidingo sokudala isikhunta sesibili, futhi kunikeza amathuba angenamkhawulo wokuklama ngaphandle kwemingcele ekubunjweni. Ukusika i-Laser kunikeza ukucutshungulwa kwephethini enembile futhi eyinkimbinkimbi, okwenza kube yisixazululo sokumisa okukodwa ngaphandle kwesidingo sokucutshungulwa kwesibili.

Ukusika iphepha nge-laser kusebenzisa imishayo ye-laser enamandla amakhulu ukusika ngokuhlanzekile nokudala amaphethini angenalutho ayinkimbinkimbi ephepheni. Ngokudlulisela ihluzo ozifisayo kukhompuyutha, ukufeza umphumela oyifunayo kuba lula. Imishini yokusika nokuqopha i-laser, enomklamo wayo oyingqayizivele kanye nokucushwa okusebenza kahle kakhulu, ithuthukisa kakhulu ukusebenza kahle komsebenzi, ibenze imishini ebalulekile embonini yomkhiqizo wephepha.

Isibonisi Sevidiyo | indlela yokusika i-laser nokuqopha iphepha

ongakufunda kule vidiyo:

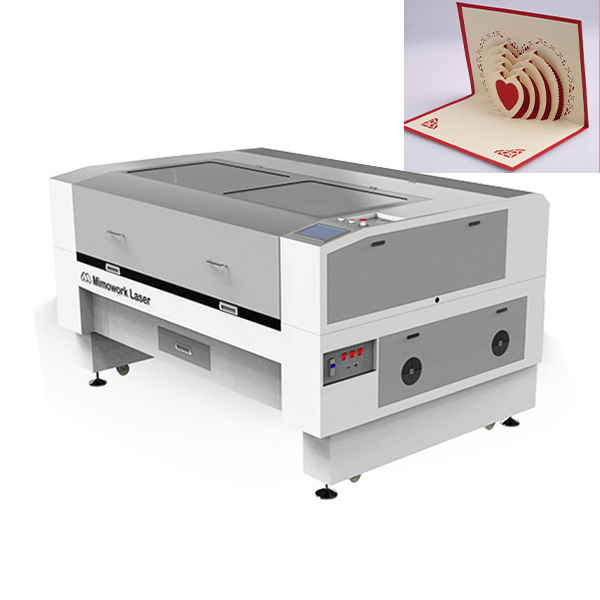

Kule vidiyo, uzophenya ekusethweni kwe-CO2 laser eqoshiwe kanye nokusika kwe-laser ebhodini lephepha, uthole izici zayo ezimangalisayo namandla. Udume ngesivinini nokunemba kwawo, lo mshini wokumaka we-laser uletha imiphumela emihle yephephabhodi eqoshwe nge-laser futhi unikeza ukuguquguquka ekusikeni iphepha elinobumo obuhlukahlukene. Ukusebenza kwayo okusebenziseka kalula kwenza ifinyeleleke ngisho nakubaqalayo, kuyilapho ukusika nokuqopha nge-laser okuzenzakalelayo kwenza yonke inqubo ibe lula futhi isebenziseke kalula.

▶ Izinzuzo Ezihlukile Zephepha Lokusika I-Laser Uma liqhathaniswa Nokuphrinta Uyinki noma Ukusika I-Die:

1.Indawo yokusebenza eguquguqukayo ifanele amahhovisi, izitolo, noma izitolo zokuphrinta.

2. Ubuchwepheshe obuhlanzekile nobuphephile obudinga ukuhlanzwa kwamalensi kuphela.

3. Ezomnotho ngezindleko eziphansi zokunakekela, azikho izinto ezisetshenziswayo, futhi asikho isidingo sokukhunta.

4. Ukucubungula okunembile kwemiklamo eyinkimbinkimbi.

5. Ukusebenza okuningi:ukumakwa kwendawo, ukubhobozwa okuncane, ukusika, ukufaka amagoli, amaphethini, umbhalo, amalogo, nokunye ngenqubo eyodwa.

6.Inobungani bemvelo ngaphandle kwezithasiselo zamakhemikhali.

I-7.Ukukhiqiza okuguquguqukayo kwamasampuli angashadile noma ukucubungula kwe-batch encane.

8. Xhuma futhi udlale ngaphandle kokucubungula okwengeziwe okudingekayo.

▶Izicelo ezifanele:

Amakhadi ebhizinisi omuntu siqu, amakhadi okubingelela, ama-scrapbook, izibonisi zokuphromotha, ukupakishwa, imisebenzi yezandla, amakhava namajenali, amabhukumaka, nemikhiqizo yephepha ehlukahlukene, okuthuthukisa ikhwalithi yomkhiqizo.

Imishini yokusika i-laser ingakwazi ukusika ngokushesha izinhlobo ezahlukene zephepha ngaphandle kwemiphumela emibi esekelwe ekugqileni kwephepha, okuhlanganisa ukusika iphepha, amabhokisi ephepha, kanye nemikhiqizo yephepha ehlukahlukene. Iphepha lokusika i-laser linamandla amakhulu ngenxa yemvelo yalo yokungabi nasikhunta, livumela noma yisiphi isitayela sokusika, ngaleyo ndlela linikeze ukuguquguquka okuphezulu. Ngaphezu kwalokho, imishini yokusika iphepha le-laser inikeza ukunemba okuyingqayizivele, enye yezinzuzo zayo ezibalulekile, ngaphandle kwamandla angaphandle acindezelayo noma abangela ukubola ngesikhathi sokusika.

Ukubuka Kwevidiyo | ukusika iphepha

Izici Ezibalulekile Zomshini Othembekile Wokusika I-Laser:

1. Indawo yokusika ebushelelezi engenawo ama-burrs.

2. Imithungo yokusika izacile, ngokuvamile esukela ku-0.01 kuya ku-0.20 amasentimitha.

3. Ifanele ukucubungula imikhiqizo emikhulu, igwema izindleko eziphezulu zokukhiqiza isikhunta.

4. Ukuguqulwa kwe-thermal okuncane ngenxa yamandla agxilile kanye nemvelo yesivinini esikhulu sokusika kwe-laser.

5. Ilungele ukwenza i-prototyping esheshayo, ifinyeze umjikelezo wokuthuthukiswa komkhiqizo.

6. Amakhono okonga impahla ngohlelo lwekhompuyutha, ukwandisa ukusetshenziswa kwezinto ezibonakalayo.

▶ Amathiphu okusika i-Laser Paper:

- Sebenzisa ilensi enobude bokugxila obufushane kakhulu ukuze uthole indawo ye-laser ecolekile kanye nokunemba okwandisiwe.

- Ukuze uvimbele ukushisa ngokweqile kwephepha, sebenzisa okungenani u-50% wesivinini esiphezulu se-laser.

- Imishayo ye-laser ekhanyayo eshaya itafula lensimbi ngesikhathi sokusikwa ingashiya amamaki ngemuva kwephepha, ngakho-ke kutuswa ukusebenzisa Umbhede We-Laser Wezinyosi noma Ithebula Lommese.

- Ukusika i-laser kukhiqiza intuthu nothuli olungahlala futhi lungcolise iphepha, ngakho-ke kuyatuseka ukusebenzisa isikhipha intuthu.

Umhlahlandlela Wevidiyo | Hlola Ngaphambi Kokwenza I-Multilayer Laser Cutting

ongakufunda kule vidiyo:

Ividiyo ithatha i-multilayer laser cutting paper njengesibonelo, inselele umkhawulo womshini wokusika we-CO2 laser futhi ibonise ikhwalithi enhle kakhulu yokusika lapho i-galvo laser iqopha iphepha. zingaki izingqimba laser ezingasika ucezu lwephepha? Njengoba ukuhlolwa kubonisiwe, kungenzeka kusukela ekusikeni kwe-laser izingqimba ezi-2 zephepha kuya ekusikeni kwe-laser izingqimba zephepha eziyi-10, kodwa izendlalelo eziyi-10 zingase zibe sengcupheni yokushiswa kwephepha. Kuthiwani nge-laser ukusika izingqimba ezi-2 zendwangu? Kuthiwani ngendwangu ehlanganisiwe ye-laser yokusika isangweji? Sihlola i-laser cutting Velcro, izingqimba ezi-2 zendwangu kanye ne-laser yokusika izendlalelo ezi-3 zendwangu.

Uyafuna Ukuqala Ekhanda?

Kuthiwani Ngalezi Zikhetho Ezinhle?

Ufuna Ukuqalisa Nge-Laser Cutter & Engraver Khona Khona?

Xhumana Nathi Ukuze Ubuze Ukuze Uqalise Ngokushesha!

▶ Mayelana Nathi - I-MimoWork Laser

Asiyikhokhi imiphumela Emaphakathi

I-Mimowork ingumkhiqizi we-laser ogxile emiphumeleni, ozinze e-Shanghai nase-Dongguan China, iletha ubuchwepheshe bokusebenza obujulile beminyaka engu-20 ukukhiqiza izinhlelo ze-laser futhi inikeze izixazululo eziphelele zokucubungula nokukhiqiza kuma-SME (amabhizinisi amancane naphakathi) ezimbonini eziningi eziningi.

Umuzwa wethu ocebile wezixazululo ze-laser zokucubungula izinto zensimbi nezingezona ezensimbi ugxile kakhulu ekukhangiseni komhlaba wonke, ezezimoto & ezondiza, i-metalware, izinhlelo zokusebenza ze-sublimation kadayi, imboni yendwangu kanye nezindwangu.

Kunokuba inikeze isixazululo esingaqinisekile esidinga ukuthengwa kubakhiqizi abangafanelekile, iMimoWork ilawula yonke ingxenye yochungechunge lokukhiqiza ukuze iqinisekise ukuthi imikhiqizo yethu isebenza kahle kakhulu.

I-MimoWork izibophezele ekudaleni nasekuthuthukiseni ukukhiqizwa kwe-laser futhi yathuthukisa inqwaba yobuchwepheshe be-laser obuthuthukisiwe ukuze ithuthukise umthamo wokukhiqiza wamakhasimende kanye nokusebenza kahle okukhulu. Ukuthola amalungelo obunikazi amaningi obuchwepheshe be-laser, sihlala sigxile kwikhwalithi nokuphepha kwezinhlelo zemishini ye-laser ukuze siqinisekise ukukhiqizwa kokucubungula okungaguquki nokuthembekile. Ikhwalithi yomshini we-laser iqinisekiswe yi-CE kanye ne-FDA.

I-MimoWork Laser System ingakwazi ukusika i-Acrylic ne-laser eqoshwe i-Acrylic, ekuvumela ukuthi uqalise imikhiqizo emisha yezimboni ezihlukahlukene. Ngokungafani nabasiki bokugaya, ukuqopha njengento yokuhlobisa kungafinyelelwa ngemizuzwana ngokusebenzisa umqophi we-laser. Kuphinde kukunike ithuba lokuthatha ama-oda abe mancane njengomkhiqizo owenziwe ngezifiso weyunithi eyodwa, futhi amakhulu njengezinkulungwane zemikhiqizo esheshayo ngamaqoqo, konke ngaphakathi kwamanani okutshala imali athengekayo.

Thola Imibono Eminye Esiteshini Sethu Se-YouTube

Isikhathi sokuthumela: Jul-18-2023