I-Laser Welding Secrets: Lungisa Izinkinga Ezivamile Manje!

Isingeniso:

Umhlahlandlela Ophelele Wokuxazulula Inkinga

Ephathwayo Laser Welding Machines

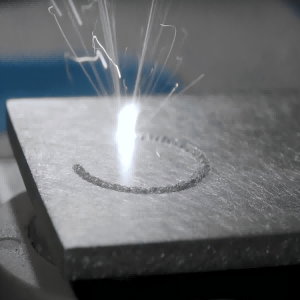

Umshini wokushisela i-laser we-handheld fiber usuzuze ukuthandwa okukhulu ezimbonini ezahlukahlukene ngenxa yokunemba nokusebenza kahle kwawo.

Kodwa-ke, njenganoma iyiphi enye indlela yokushisela, ayivikelekile ezinseleleni nasezinkingeni ezingase ziphakame phakathi nenqubo yokushisela.

Lokhu okuphelelelaser Welding ukuxazulula izinkingaihlose ukubhekana nezinkinga ezivamile okuhlangatshezwana nazo ngemishini yokushisela i-laser ephathwayo, izinkinga ezihlobene nokushisela, kanye nezindaba eziphathelene nekhwalithi yokushisela.

Amaphutha Nezixazululo Zomshini Wokushisela we-Laser

1. Izisetshenziswa azikwazi ukuqala (Amandla)

Isixazululo: Hlola ukuthi iswishi yentambo yamandla iyasebenza yini.

2. Izibani azikwazi ukukhanyiswa

Isixazululo: Hlola ibhodi langaphambi komlilo noma ngaphandle kwe-voltage engu-220V, hlola ibhodi elikhanyayo; 3 I-fuse, isibani se-xenon.

3. Ukukhanya Kukhanyisiwe, Akukho Laser

Isixazululo: Qaphela umshini wokushisela we-laser ophethwe ngesandla ingxenye yesibonisi esiphuma ekukhanyeni ijwayelekile. Okokuqala, hlola ukuthi ingxenye ye-CNC yenkinobho ye-laser ivaliwe, uma ivaliwe, bese uvula inkinobho ye-laser. Uma inkinobho ye-laser ijwayelekile, vula isixhumi esibonakalayo sokulawula izinombolo ukuze ubone ukuthi ukulungiselelwa kokukhanya okuqhubekayo, uma kungenjalo, bese ushintshela ekukhanyeni okuqhubekayo.

Izinkinga ze-Welding Phase Laser Welder & Fixes

I-Weld Seam Imnyama

Igesi yokuvikela ayivuliwe, inqobo nje uma igesi ye-nitrogen ivuliwe, ingaxazululwa.

Isiqondiso sokugeleza komoya kwegesi evikelayo akulungile, isiqondiso sokuhamba komoya segesi elivikelayo kufanele senziwe ngokuphambene nokuqondisa kokunyakaza komsebenzi.

Ukuntuleka Kokungena Ekushiseleni

Ukungabi namandla kwe-laser kungathuthukisa ububanzi be-pulse kanye namanje.

Ilensi yokugxila ayilona inani elilungile, ukulungisa inani lokugxila eduze nendawo yokugxila.

Ukuncipha Kwe-Laser Beam

Uma amanzi okupholisa engcolile noma engazange ashintshwe isikhathi eside, angaxazululwa ngokufaka amanzi okupholisa nokuhlanza ishubhu lengilazi le-UV nesibani se-xenon.

Ilensi egxilile noma i-diaphragm ye-resonant cavity ye-laser yonakalisiwe noma ingcolile, kufanele ishintshwe noma ihlanzwe ngesikhathi.

Hambisa i-laser endleleni enkulu yokubona, lungisa isamba sokubonisa kanye ne-semi-reflection diaphragm kumzila oyinhloko wokubona, hlola futhi uzungelezele indawo ngephepha lesithombe.

I-laser ayikhiphi kumbhobho wethusi ngaphansi kwekhanda eligxilile. Lungisa i-diaphragm engu-45-degree reflective ukuze i-laser iphume phakathi nendawo yomlomo wegesi.

I-Laser Welding Quality Troubleshooting

1.I-Spatter

Ngemva kokuqedwa kwe-laser welding, izinhlayiya eziningi zensimbi zivela ebusweni bento noma ucezu lomsebenzi, olunamathiselwe ebusweni bento noma ucezu lomsebenzi.

Isizathu sokufafaza: ubuso bezinto ezicutshunguliwe noma ucezu lomsebenzi aluhlanzekile, kunamafutha noma ukungcola, kungase futhi kubangelwe ukuguquguquka kongqimba lwama-galvanized.

1) Naka ukuhlanza impahla noma ucezu umsebenzi ngaphambi laser Welding;

2) I-Spatter ihlobene ngokuqondile nokuminyana kwamandla. Ukwehliswa okufanele kwamandla okushisela kunganciphisa i-spatter.

2. Imifantu

Uma isivinini sokupholisa se-workpiece sishesha kakhulu, izinga lokushisa lamanzi okupholisa kufanele lilungiswe ku-fixture ukuze kwandiswe izinga lokushisa lamanzi.

Uma igebe lokulingana kwe-workpiece likhulu kakhulu noma kune-burr, ukunemba komshini we-workpiece kufanele kuthuthukiswe.

I-workpiece ayizange ihlanzwe. Kulokhu, i-workpiece idinga ukuhlanzwa futhi.

Izinga lokugeleza kwegesi elivikelayo likhulu kakhulu, elingaxazululwa ngokunciphisa izinga lokugeleza kwegesi elivikelayo.

3. Imbobo Ku-Weld Surface

Izizathu zokwakhiwa kwe-porosity:

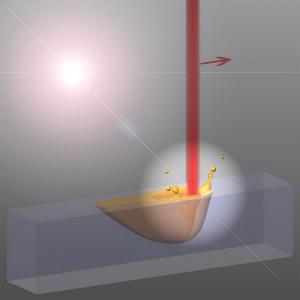

1) I-laser welding pool encibilikisiwe ijulile futhi incane, futhi izinga lokupholisa liyashesha kakhulu. Igesi ekhiqizwe echibini elincibilikisiwe seliphuze kakhulu ukuthi lingachichima, okungaholela ekwakhekeni kwe-porosity.

2) Ubuso be-weld abuhlanzwa, noma umhwamuko we-zinc weshidi eliphehliwe uvuthwa.

Hlanza ingaphezulu le-workpiece kanye nobuso be-weld ngaphambi kokushisela ukuze uthuthukise ukuvuthwa kwe-zinc lapho kushisa.

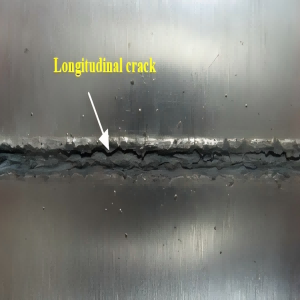

4. Ukuphambuka kokushisela

Insimbi yokushisela ngeke iqine phakathi nendawo yesakhiwo esihlangene.

Isizathu sokuphambuka: Ukuma okungalungile ngesikhathi sokushisela, noma isikhathi sokugcwalisa esingalungile nokuqondisa kwezintambo.

Isixazululo: Lungisa indawo yokushisela, noma isikhathi sokugcwalisa nendawo yocingo, kanye nendawo yesibani, ucingo kanye ne-weld.

5. I-Slag Entrapment, Evela Ngokuyinhloko Phakathi Kwezendlalelo

Ukufakwa kwe-slag ebusweni kubangela:

1) Lapho multi-layer multi-pass Welding, enamathela phakathi izingqimba akuhlanzekile; noma ingaphezulu le-weld yangaphambilini ayisicaba noma ingaphezulu le-weld alihlangabezani nezidingo.

I-2) Amasu okusebenza okushisela okungalungile, njengamandla okufakwayo okushisela okuphansi, isivinini sokushisela siyashesha kakhulu.

Isixazululo: Khetha ijubane lokushisela lamanje kanye nesivinini sokushisela, futhi ukufakwa kwe-interlayer kufanele kuhlanzwe uma ukufakwa kwe-multi-layer multi-pass welding. Gaya futhi ususe i-weld nge-slag ebusweni, futhi wenze i-weld uma kunesidingo.

Ezinye Izesekeli - I-Handheld Laser Welder Izinkinga Ezivamile Nezixazululo

1. Ukwehluleka Kwedivayisi Yokuvikela Ukuphepha

Imishini yokuvikela ukuphepha yomshini wokushisela i-laser, njengomnyango wegumbi lokushisela, inzwa yokugeleza kwegesi, nenzwa yokushisa, ibalulekile ekusebenzeni kwayo ngendlela efanele. Ukuhluleka kwalezi zisetshenziswa akukwazi nje ukuphazamisa ukusebenza okuvamile kwesisetshenziswa kodwa futhi kubangela ingozi yokulimala ku-opharetha.

Uma kwenzeka ukungasebenzi kahle kwemishini yokuvikela ukuphepha, kubalulekile ukumisa ukusebenza ngesikhathi esisodwa bese uthintana nochwepheshe ukuze balungiswe futhi bashintshwe.

2. I-wire feeder Jamming

Uma kukhona i-wire feeder jam kulesi simo, into yokuqala okudingeka siyenze ukuhlola ukuthi isibhamu sesibhamu sivalekile yini, isinyathelo sesibili ukuhlola ukuthi i-wire feeder ivalekile futhi kukhona ukujikeleza kwediski kasilika kuyinto evamile.

Fingqa

Ngokunemba okungenakuqhathaniswa, isivinini nokuguquguquka, i-laser welding iwubuchwepheshe obubalulekile ezimbonini ezinjengezezimoto, i-aerospace kanye ne-electronics.

Kodwa-ke, ukukhubazeka okuhlukahlukene kungase kwenzeke ngesikhathi senqubo yokushisela, okuhlanganisa i-porosity, ukuqhekeka, ukuqhuma, ubuhlalu obungavamile, ukushiswa, ukuguqulwa, kanye ne-oxidation.

Isici ngasinye sinembangela ethile, njengezilungiselelo ze-laser ezingafanele, ukungcola okubonakalayo, amagesi okuvikela anganele, noma amalunga angahambi kahle.

Ngokuqonda lezi zinkinga nezimbangela zazo, abakhiqizi bangasebenzisa izixazululo eziqondiwe, ezifana nokwenza kahle imingcele ye-laser, ukuqinisekisa ukuhlangana okufanele kwamalunga, ukusebenzisa amagesi okuvikela ekhwalithi ephezulu, nokusebenzisa ukwelashwa kwangaphambili nangemuva kokushisela.

Ukuqeqeshwa okufanele komsebenzisi, ukugcinwa kwemishini yansuku zonke kanye nokuqapha inqubo yesikhathi sangempela kuqhubekisela phambili ukuthuthukisa ikhwalithi yokushisela futhi kunciphise amaphutha.

Ngendlela ebanzi yokuvimbela amaphutha kanye nokwenza ngcono inqubo, i-laser welding iletha ngokungaguquki ama-welds aqinile, athembekile futhi aphezulu ahlangabezana nezindinganiso eziqinile zemboni.

Angazi ukuthi yiluphi uhlobo lomshini wokushisela we-laser ongawukhetha?

Udinga ukwazi: Ungakhetha kanjani umshini we-laser ophethwe ngesandla

I-High-Capacity & Wattage yezinhlelo zokusebenza zokushisela ezihlukahlukene

Umshini wokushisela we-laser ongu-2000W ubonakala ngosayizi womshini omncane kodwa ikhwalithi yokushisela ekhazimulayo.

Umthombo we-fiber laser ezinzile kanye nekhebula lefayibha exhunyiwe inikeza ukulethwa kwe-laser beam ephephile futhi engaguquki.

Ngamandla aphezulu, i-laser welding keyhole iphelele futhi yenza i-welding joint firmer iqine ngisho nangensimbi ewugqinsi.

Ukuphatheka kokuvumelana nezimo

Ngokubukeka komshini ohlangene futhi omncane, umshini we-laser welder ophathwayo ufakwe isibhamu se-laser esiphathwayo esinyakazayo esingasindi futhi esilungele ukusetshenziswa kwe-multi-laser welding kunoma iyiphi i-engeli nangaphezulu.

Izinhlobo ezihlukahlukene zokuzikhethela ze-laser welder nozzle kanye nezinhlelo zokuphakela izintambo ezizenzakalelayo zenza ukusebenza kwe-laser welding kube lula futhi lokho kube nobungane kwabaqalayo.

I-high-speed laser welding kukhulisa kakhulu ukusebenza kahle kwakho kokukhiqiza kanye nokuphumayo kuyilapho kunika amandla umphumela omuhle kakhulu we-laser welding.

Izinto Odinga Ukuzazi mayelana: Handheld Laser Welding

Uma uyijabulele le vidiyo, kungani ungacabangiubhalisela Isiteshi sethu se-YouTube?

Konke Okuthengiwe Kufanele Kwaziswe Kahle

Singasiza Ngolwazi Oluningiliziwe kanye Nokubonisana!

Isikhathi sokuthumela: Jan-16-2025