Ukwenza ama-Swimsuits nge-Fabric Laser Cutting Machines Ubuhle Nebubi

i-laser cut swimsuit nge-laser cutter yendwangu

Ama-Swimsuits ayingubo ethandwayo edinga ukusika nokuthunga ngokunemba ukuze kuqinisekiswe ukulingana okukhululekile nokuvikelekile. Ngokutholakala okwandayo kwemishini yokusika i-laser yendwangu, abanye bacabanga ukusebenzisa lobu buchwepheshe ukwenza izingubo zokubhukuda. Kulesi sihloko, sizohlola ubuhle nobubi bokusebenzisa abasiki bendwangu ye-laser ukwenza izingubo zokubhukuda.

Izinzuzo

• Ukusika Ngokunemba

Enye yezinzuzo eziyinhloko zokusebenzisa umshini wokusika we-laser wendwangu ukwenza ama-swimsuits ukusika okunembayo okunikezayo. I-laser cutter ingakha imiklamo enembile neyinkimbinkimbi enemiphetho ehlanzekile, ikwenze kube lula ukusika ubujamo obuyinkimbinkimbi namaphethini endwangu ye-swimsuit.

• Ukusebenza Kwesikhathi

Ukusebenzisa i-laser fabric cutter kungasindisa isikhathi enqubweni yokukhiqiza ngokuzenzakalelayo inqubo yokusika. I-laser cutter ingasika izingqimba eziningi zendwangu ngesikhathi esisodwa, inciphise isikhathi esidingekayo sokusika nokwenza ngcono ukukhiqiza okuphelele.

• Ukwenza ngokwezifiso

Imishini yokusika i-laser yendwangu ivumela ukwenza ngokwezifiso imiklamo ye-swimsuit. Umshini ungasika izinhlobonhlobo zamajamo namaphethini, okwenza kube nokwenzeka ukudala imiklamo eyingqayizivele kanye nokulingana ngokwezifiso kumakhasimende.

• Ukusebenza Kwezinto Ezibalulekile

Imishini yokusika i-laser yendwangu ingabuye ithuthukise ukusebenza kahle kwezinto ngokunciphisa imfucuza yendwangu. Umshini ungahlelwa ukuze uthuthukise ukusetshenziswa kwendwangu ngokunciphisa isikhala phakathi kokusikeka, okunganciphisa inani lendwangu ye-scrap ekhiqizwa ngesikhathi sokusika.

Ububi

• Izidingo Zokuqeqesha

Ukusebenzisa i-laser cutting for fabrics kudinga ukuqeqeshwa okukhethekile ukuze kusebenze. Umsebenzisi kufanele abe nokuqonda okuhle kwamakhono nemikhawulo yomshini, kanye nezimiso zokuphepha ukuze kuqinisekiswe ukuphepha komsebenzisi nabanye endaweni yokusebenza.

• Ukuhambisana Kwezinto ezibonakalayo

Akuzona zonke izindwangu ezihambisana nemishini yokusika laser. Izindwangu ezithile, njengalezo ezinendawo ekhanyayo noma izintambo zensimbi, zingase zingafaneleki ukusikwa nge-laser ngenxa yengozi yomlilo noma yokulimala komshini.

• Ukusimama

Ukusebenzisa indwangu laser cutting imishini ukwenza swimsuits kuphakamisa ukukhathazeka mayelana nokusimama. Umshini udinga ugesi ukuze usebenze, futhi inqubo yokukhiqiza ingadala imfucuza ngesimo sentuthu nentuthu. Ukwengeza, ukusetshenziswa kwezindwangu zokwenziwa ezivame ukusetshenziselwa izingubo zokubhukuda kuphakamisa ukukhathazeka mayelana nokungcoliswa kwe-microplastic kanye nomthelela wemvelo wokukhiqiza nokulahlwa.

• Izindleko Zezisetshenziswa

Enye yezingqinamba ezinkulu zokusebenzisa i-Fabric laser cutter ukwenza izingubo zokubhukuda yizindleko zemishini. Imishini yokusika i-laser ingabiza, futhi lezi zindleko zingase zibe nkulu kumabhizinisi amancane noma abantu ngabanye.

Ekuphetheni

Ukusebenzisa indwangu laser cutting imishini ukwenza swimsuits has kokubili okuhle nokubi. Ngenkathi ukusika okunembayo nokusebenza kahle kwesikhathi komshini kungathuthukisa ukukhiqiza kanye nezinketho zokwenza ngokwezifiso, izindleko eziphezulu zemishini, izidingo zokuqeqesha, ukuhambisana kwezinto ezibonakalayo, nokukhathazeka kokusimama kufanele kucatshangelwe. Ekugcineni, isinqumo sokusebenzisa i-laser fabric cutter ukukhiqizwa kwe-swimsuit sizoncika ezidingweni ezithile kanye nezinto eziza kuqala zebhizinisi noma zomuntu ngamunye.

Isibonisi Sevidiyo | Glance for Laser Cutting Swimwear

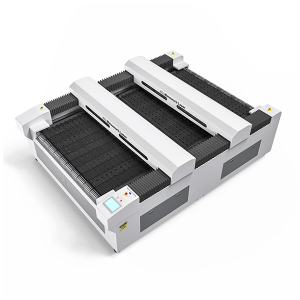

Kunconyiwe Indwangu laser cutter

Noma yimiphi imibuzo mayelana nokusebenza kwe-Fabric Laser Cutter?

Isikhathi sokuthumela: Apr-12-2023