Umhlahlandlela Wokugcina Wendwangu Yokuhlunga I-Laser:

Izinhlobo, Izinzuzo, kanye nezicelo

Isingeniso:

Izinto Ezibalulekile Okufanele Uzazi Ngaphambi KokuDibela

Izindwangu zokuhlunga zidlala indima ebalulekile ezimbonini eziningi ezihlukene, kusukela ekuhlungeni kwamanzi nomoya kuya ekwenziweni kwemithi nokudla. Njengoba amabhizinisi efuna ukuthuthukisa ukusebenza kahle, ukunemba, nokwenza ngokwezifiso ekukhiqizeni indwangu yokuhlunga, indwangu yokuhlunga i-laser iye yavela njengesixazululo esithandwayo. Ngokungafani nezindlela zokusika zendabuko, indwangu yokuhlunga ye-laser inikeza izinga eliphezulu lokunemba, isivinini, kanye nemfucuza encane yezinto ezibonakalayo, okwenza kube ukukhetha okuhle kokusika izindwangu zokuhlunga ezenziwe ngezinto ezihlukahlukene ezifanai-polyester, inayiloni, futhiizindwangu ezingalukiwe.

Kulesi sihloko, sizobheka kabanzi izinhlobo ezahlukene zendwangu yokuhlunga nokuthi indwangu yokuhlunga i-laser isebenza kanjani ezintweni ezihlukahlukene. Uzobona ukuthi kungani kubeikhambi lokuya ekukhiqizeni izinga eliphezulu, imikhiqizo yokuhlunga eyenziwe ngezifiso. Sizophinde sabelane ngemininingwane evela ekuhlolweni kwethu kwakamuva ngezinto ezifana negwebu ne-polyester, sikunikeza izibonelo zomhlaba wangempela zokuthi indwangu yokuhlunga i-laser ingathuthukisa kanjani ukusebenza kahle nokuvumelana ekukhiqizeni.

Indlela Yokusika Indwangu Yokuhlunga I-Laser | Laser Cutting Machine for Filtration Industry

Woza kuvidiyo ukuze uhlole inqubo yokusika i-laser yendwangu yokuhlunga. Isidingo esikhulu sokusika ukunemba senza umshini wokusika we-laser embonini yokuhlunga.

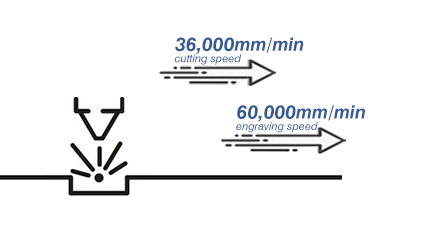

Amakhanda e-laser aphindwe kabili athuthukisa ukukhiqizwa, akhuphule isivinini sokusika ngenkathi eqinisekisa ikhwalithi.

1. Indwangu yesihlungi se-Polyester:

• Ukusetshenziswa:Indwangu yokuhlunga i-polyester ingenye yezinto ezisetshenziswa kakhulu ekuhlungeni ngenxa yokuqina kwayo, ukumelana namakhemikhali, kanye nekhono lokumelana namazinga okushisa aphezulu.

•Izicelo:Ivamise ukusetshenziswa ezinhlelweni zokuhlunga komoya, ukwelashwa kwamanzi, nezinhlelo zokuhlunga zezimboni.

•Izinzuzo zokusika i-Laser:I-polyester iyahambisana kakhululaser cutting isihlungi indwangungoba ikhiqiza imiphetho ehlanzekile, eqondile. Ilaser iphinde ivale imiphetho, ivimbele ukubola futhi ithuthukise amandla endwangu.

2. Indwangu Yesihlungi Inayiloni:

• Ukusetshenziswa:Yaziwa ngokuguquguquka nokuqina kwayo, indwangu yesihlungi senayiloni ilungele ukufunwa izicelo zokuhlunga, njengezimboni zamakhemikhali noma emkhakheni wokudla neziphuzo.

•Izicelo:Okuvame ukusetshenziselwa ukuhlunga kwamakhemikhali, ukwelashwa kwamanzi, nokuhlunga kokucubungula ukudla.

•Izinzuzo zokusika i-Laser:Amandla enayiloni nokumelana nokugqoka kuyenza ibe ikhandidethi elihle kakhulu kuyolaser cutting isihlungi indwangu. I-laser iqinisekisa imiphetho ebushelelezi, evaliwe egcina ukuqina kwempahla kanye nezakhiwo zokuhlunga.

3. Indwangu Yesihlungi Se-Polypropylene:

• Ukusetshenziswa:I-Polypropylene yaziwa ngokumelana kwayo namakhemikhali okuhle kakhulu, okuyenza ilungele ukuhlunga amakhemikhali anolaka noma izinto ezinezinga eliphezulu lokushisa.

•Izicelo:Isetshenziswa ekuhlungeni kwemithi, ekuhlungeni izimboni, nasekuhlungeni uketshezi.

•Izinzuzo zokusika i-Laser: Indwangu yokuhlunga ye-lasernjenge-polypropylene ivumela ukusikeka okunembile kanye nemiklamo eyinkimbinkimbi ngaphandle kokulimaza impahla. Amaphethelo avaliwe ahlinzeka ngobuqotho obungcono besakhiwo, okuyenza ifaneleke izinhlelo zokusebenza ezibucayi.

4. Indwangu Yesihlungi Engalukiwe:

• Ukusetshenziswa:Indwangu yokuhlunga engalukiwe ayisindi, iyagobeka, futhi iyonga. Isetshenziswa ezinhlelweni lapho ukusetshenziswa kalula nokucindezela okuphansi kubalulekile.

•Izicelo:Isetshenziswa ekuhlungeni izimoto, emoyeni, nasezintulini, kanye nasemikhiqizweni yokuhlunga elahlwayo.

•Izinzuzo zokusika i-Laser:Izindwangu Nonwoven kungabaukusika kwe-laserngokushesha nangempumelelo.Indwangu yokuhlunga ye-laseriguquguquka kakhulu ngezidingo ezahlukahlukene zokuhlunga, okuvumela ukubhoboza okuhle nokusikeka kwendawo enkulu.

Indwangu yesihlungi sokusika i-laser isebenzisa induku ye-laser egxilile, enamandla amakhulu encibilikisa noma ehwamulise indwangu khona kanye lapho kuthintana khona. Iqondiswa uhlelo lwe-CNC (Computer Numerical Control), i-laser ihamba ngokunemba okumangalisayo, okwenza kube nokwenzeka ukusika noma ngisho nokuqopha izinhlobo ezahlukene zendwangu yokuhlunga ngokunemba okuvelele.

Yiqiniso, akuzona zonke izinto zendwangu yokuhlunga ezifanayo. Ngayinye idinga izilungiselelo ezicushwe kahle ukuze kuzuzwe imiphumela engcono kakhulu yokusika. Ake sihlukanise ukuthi indwangu yokuhlunga i-laser isebenza kanjani kwezinye zezinto ezisetshenziswa kakhulu.

I-Laser Cut Polyester:

Indwangu yesihlungi se-polyester iqinile futhi imelana nokunwebeka, okungenza kube nzima ukusika ngamathuluzi endabuko. Ukusika i-laser kunikeza inzuzo ecacile lapha, njengoba iletha imiphetho ebushelelezi, evaliwe evimbela ukubola ngenkathi igcina amandla endwangu. Lokhu kunemba kubaluleke kakhulu ezimbonini ezifana nokuhlanza amanzi noma ukucutshungulwa kokudla, lapho kudingeka khona ukusebenza kwesihlungi okungaguquki.

I-Laser Cut Indwangu Engalukiwe:

Izindwangu ezingalukiwe azisindi futhi zithambile, okuzenza zifanelane kahle kakhulu nokusika i-laser. Ngalobu buchwepheshe, okubalulekile kungacutshungulwa ngokushesha ngaphandle kokuphazamisa ukwakheka kwayo, okuholela ekusikeni okuhlanzekile, okunembayo okubalulekile ekubumbeni izihlungi. Le ndlela ibaluleke kakhulu uma usebenza nezindwangu ezingalukiwe ekuhlungeni kwezokwelapha noma kwezimoto, lapho ukunemba nokuvumelana kuyisihluthulelo.

I-Laser Cut Inayiloni:

Izindwangu zenayiloni zaziwa ngokuguquguquka kwazo nokuqina, kodwa zingaba nzima ukuphatha ngezindlela zokusika ngomshini. Ukucubungula nge-laser kuxazulula le nselele ngokukhiqiza ukusikeka okubukhali, okunembile ngaphandle kokudala ukuhlanekezela. Umphumela uba izihlungi ezibamba umumo wazo futhi zilethe ukusebenza okuthembekile, okubalulekile ezindaweni ezidinga kakhulu ezifana nemikhiqizo yamakhemikhali noma yemithi.

I-Laser Cut Foam:

Igwebu liyinto ethambile futhi enezimbotshana engadabula noma igoqeke kalula uma isikwa ngezindwani. Ubuchwepheshe be-laser bunikeza isisombululo esihlanzekile nesithembekile, njengoba sinqamula igwebu ngokushelela ngaphandle kokuchoboza amaseli noma ukubeka engcupheni ukwakheka kwawo. Lokhu kuqinisekisa ukuthi izihlungi ezenziwe ngegwebu zigcina i-porosity yazo nokusebenza, okuzenza zisebenziseke kakhulu ezinhlelweni ezifana nokuhlanzwa komoya kanye nokufakwa kwe-acoustic.

Kungani Khetha I-Laser Cutting Yokuhlunga Indwangu?

Indwangu yokuhlunga ye-laserinikeza izinzuzo eziningi kuzindlela zokusika zendabuko, ikakhulukazi ezintweni zendwangu yokuhlunga. Nazi ezinye zezinzuzo ezibalulekile:

1. Ukunemba kanye Nomphetho Ohlanzekile

Indwangu yokuhlunga ye-laseriqinisekisa ukusikeka okunembile ngemiphetho ehlanzekile, evalekile, okubalulekile ekugcineni ubuqotho besakhiwo sendwangu yokuhlunga. Lokhu kubaluleke kakhulu ezinhlelweni zokuhlunga lapho okubalulekile kufanele kugcine ikhono lakho lokuhlunga kahle.

2. Isivinini Esisheshayo & Ukusebenza Okuphakeme

Indwangu yokuhlunga ye-laserliyashesha futhi lisebenza ngempumelelo kunezindlela eziwumshini noma zokusika, ikakhulukazi imiklamo eyinkimbinkimbi noma engokwezifiso. Iisihlungi indwangu laser cutting uhleloingabuye izenzekele, inciphise isidingo sokungenelela mathupha futhi isheshise izikhathi zokukhiqiza.

3. Ukulahlwa Kwezinto Ezincane

Izindlela zokusika zendabuko zivame ukudala imfucuza yezinto ezibonakalayo, ikakhulukazi lapho usika izimo eziyinkimbinkimbi.Indwangu yokuhlunga ye-laserinikeza ukunemba okuphezulu nokumoshwa kwezinto ezincane, okwenza kube inketho engabizi kakhulu kukho kokubili ukukhiqizwa okuncane nokukhulu.

4. Ukwenza ngokwezifiso kanye nokuvumelana nezimo

Indwangu yokuhlunga ye-laserivumela ukwenziwa ngokwezifiso okuphelele kwezindwangu zokuhlunga. Kungakhathaliseki ukuthi udinga ama-perforations amancane, izimo ezithile, noma imiklamo enemininingwane,laser cutting isihlungi indwanguingakwazi ukubhekana nezidingo zakho kalula, ikunikeze ukuguquguquka kokukhiqiza imikhiqizo eminingi yendwangu yokuhlunga.

5. Akukho Ukugqoka Kwamathuluzi

Ngokungafani nokusika ukufa noma ukusika ngomshini,laser cutting isihlungi indwanguakubandakanyi ukuthintana ngokomzimba nempahla, okusho ukuthi akukho ukuguga kwezindwani noma amathuluzi. Lokhu kunciphisa izindleko zokunakekelwa kanye nesikhathi sokuphumula, okwenza kube yisixazululo sesikhathi eside esithembekile.

• Indawo yokusebenza (W *L): 1000mm * 600mm

• Amandla eLaser: 60W/80W/100W

• Indawo yokusebenza (W *L): 1300mm * 900mm

• Amandla eLaser: 100W/150W/300W

• Indawo yokusebenza (W *L): 1800mm * 1000mm

• Amandla eLaser: 100W/150W/300W

Ekuphetheni

Indwangu yokuhlunga ye-laserkubonakale kuyindlela enhle kakhulu yokusika izindwangu zokuhlunga, enikeza izinzuzo eziningi njengokunemba, isivinini, kanye nokumosha okuncane. Noma ngabe usika i-polyester, igwebu, inayiloni, noma izindwangu ezingalukiwe, indwangu yokuhlunga nge-laser iqinisekisa imiphumela yekhwalithi ephezulu enemiphetho evaliwe kanye nemiklamo eyenziwe ngokwezifiso. I-MimoWork Laser yezinhlelo zokusika indwangu ye-laser ye-MimoWork inikeza isisombululo esiphelele samabhizinisi abo bonke osayizi abafuna ukuthuthukisa inqubo yabo yokukhiqiza indwangu yokuhlunga.

Xhumana nathi namuhla ukuze ufunde kabanzi mayelana nendlela yethuimishini yokusika indwangu ye-laser yokuhlungaingathuthukisa imisebenzi yakho yokusika indwangu yokuhlunga futhi ithuthukise ikhwalithi yemikhiqizo yakho.

Uma kuziwa ekukhetheni aumshini wokusika we-laser wendwangu yokuhlunga, cabangela lokhu okulandelayo:

Izinhlobo zemishini:

I-CO2 laser cutters ngokuvamile inconywa ukusika indwangu yokuhlunga ngoba i-laser ingasika ubujamo nobukhulu obuhlukahlukene. Udinga ukukhetha usayizi ofanele womshini we-laser namandla ngokuya ngezinhlobo zakho zezinto ezibonakalayo nezici. Xhumana nochwepheshe be-laser ukuze uthole iseluleko se-laser professional.

Ukuhlola Okokuqala:

Ngaphambi kokutshala imali emshinini wokusika we-laser, indlela engcono kakhulu ukwenza ukuhlolwa kwezinto ezibonakalayo usebenzisa i-laser. Ungasebenzisa isicucu sendwangu yokuhlunga bese uzama amandla ahlukene e-laser nesivinini ukuze uhlole umphumela wokusika.

Noma yimiphi Imibono mayelana Nendwangu Yokuhlunga I-Laser, Siyakwamukela Engxoxweni Nathi!

Noma yimiphi Imibuzo Ngomshini Wokusika I-Laser Wendwangu Yokuhlunga?

Kugcine ukubuyekezwa: Septhemba 9, 2025

Isikhathi sokuthumela: Nov-14-2024