Okucatshangelwayo Okuphezulu kwe-Laser Cutting Plywood

Umhlahlandlela Wokuqoshwa kwe-Wood Laser

I-Laser cut plywood inikezela ngokunemba okungenakuqhathaniswa nokuguquguquka, okuyenza ilungele yonke into kusukela kwezobuciko kuya kumaphrojekthi amakhulu. Ukuze ufinyelele emaphethelweni ahlanzekile futhi ugweme ukulimala, kubalulekile ukuqonda izilungiselelo ezifanele, ukulungiselela izinto ezibonakalayo, namathiphu okunakekela. Lo mhlahlandlela uhlanganyela ukucatshangelwa okubalulekile ukukusiza ukuthi uthole imiphumela engcono kakhulu uma usebenzisa umshini wokusika izinkuni we-laser ku-plywood.

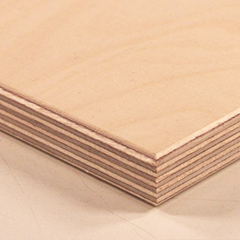

Ukukhetha iPlywood efanele

Izinhlobo Plywood Laser Cutting

Ukukhetha i-plywood efanele kubalulekile ukuze uthole imiphumela ehlanzekile nenembile ngayoi-laser cut plywoodamaphrojekthi. Izinhlobo ezahlukene ze-plywood zinikeza izinzuzo eziyingqayizivele, futhi ukukhetha okulungile kuqinisekisa ukusebenza okungcono kanye nekhwalithi yokuqeda.

I-Laser Cut Plywood

I-Birch plywood

Okuhle, okusanhlamvu okune-voids okuncane, okuhle kakhulu ekuqoshweni okuningiliziwe kanye nemiklamo eyinkimbinkimbi.

I-Popla Plywood

I-lightweight, kulula ukuyisika, ilungele amaphaneli okuhlobisa nemiklamo emikhulu.

I-Plywood ebhekene ne-Veneer

I-decorative wood veneer surface yamaphrojekthi we-premium, inikeza ukuphela kokhuni lwemvelo.

I-Specialty Thin Plywood

Amashidi azacile kakhulu okwenza amamodeli, imisebenzi yezandla, namaphrojekthi adinga ukusikeka okuthambile.

I-MDF-Core Plywood

Imiphetho yokusika ebushelelezi kanye nokuminyana okungaguquki, ilungele ukuqedwa okupendiwe noma okulamiwe.

Iyiphi I-Plywood Okufanele Ngiyikhethe Ngokusekelwe Kuzidingo Zokusika Laser?

| Ukusetshenziswa kwe-Laser Cutting | Uhlobo lwePlywood olunconyiwe | Amanothi |

|---|---|---|

| Ukuqoshwa Okunemininingwane Enhle | I-Birch | Okusanhlamvu okubushelelezi nama-voids amancane emaphethelweni acwebile |

| Ukusika Okusheshayo Ngemininingwane Emaphakathi | Poplar | Ingasindi futhi kulula ukuyisika ukuze isebenze kangcono |

| Indawo Enkulu Ukusika | I-MDF-Core | Ukuminyana okungaguquki kokusikeka okufanayo |

| Kudingeka Ukuqedwa Kwekhwalithi Ephezulu | Ubuso-Veneer | Indawo yokuhlobisa idinga izilungiselelo ezinembile |

| Izacile, Izinhlamvu Ezithambile | Okukhethekile Okuncane | Izacile kakhulu kumamodeli nemisebenzi yezandla eyinkimbinkimbi |

I-Baltic Birch Plywood

Ubukhulu bePlywood

Ukuqina kwe-plywood nakho kungathinta ikhwalithi yokusikwa kwe-laser yokhuni. I-plywood ewugqinsi idinga amandla aphezulu e-laser ukunqamula, okungadala ukuthi izinkuni zishise noma zishise. Kubalulekile ukukhetha amandla e-laser afanele kanye nesivinini sokusika ubukhulu be-plywood.

Amathiphu Okulungiselela Izinto

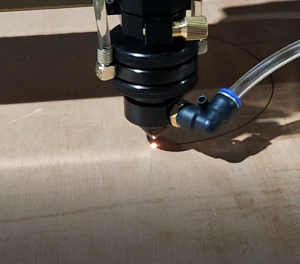

Isivinini sokusika

Ijubane lokusika ukuthi i-laser ihamba ngokushesha kangakanani ku-plywood. Isivinini sokusika esiphezulu singakhuphula ukukhiqiza, kodwa futhi singanciphisa ikhwalithi yokusika. Kubalulekile ukulinganisa isivinini sokusika nekhwalithi yokusika oyifunayo.

Laser Amandla

Amandla e-laser anquma ukuthi i-laser inganqamula ngokushesha kangakanani i-plywood. Amandla e-laser aphakeme angasika i-plywood ewugqinsi ngokushesha kunamandla aphansi, kodwa futhi angabangela ukhuni ukuba lushise noma lushise. Kubalulekile ukukhetha amandla e-laser afanele ubukhulu beplywood.

I-Laser Cutting Die Board Izinyathelo2

Laser Cutting Wood Die Board

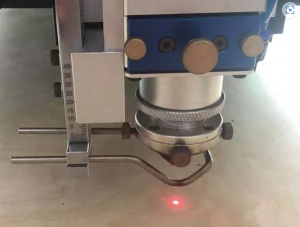

Ilensi yokugxila

Ilensi yokugxila inquma usayizi we-laser beam kanye nokujula kokusikwa. Usayizi omncane we-beam uvumela ukusikeka okunembe kakhudlwana, kuyilapho usayizi we-beam omkhulu ungasika izinto ezijiyile. Kubalulekile ukukhetha i-lens efanele yokugxilisa ubukhulu beplywood.

Usizo Lomoya

I-air assist ivuthela umoya ku-laser cutting plywood, esiza ukususa imfucumfucu futhi ivimbele ukuhangula noma ukusha. Kubaluleke kakhulu ukusika i-plywood ngoba izinkuni zingakhiqiza imfucumfucu eminingi ngesikhathi sokusika.

Usizo Lomoya

Cutting Direction

Isiqondiso lapho imishini yokusika izinkuni ze-laser i-plywood ingathinta ikhwalithi yokusika. Ukusika ngokuphambene nokusanhlamvu kungabangela ukhuni ukuba luhlakazeke noma ludabuke, kuyilapho ukusika ngokusanhlamvu kungaveza ukusika okuhlanzekile. Kubalulekile ukucabangela isiqondiso sokusanhlamvu kwezinkuni lapho uklama ukusika.

I-Laser Cutting Wood Die Doard 3

Ukubuka kwevidiyo kwe-Laser Wood Cutter

Ukucatshangelwa kokuklama

Lapho uklama ukusika kwe-laser, kubalulekile ukucabangela ukushuba kweplywood, ukuxaka komklamo, kanye nohlobo lokuhlangana olusetshenziswayo. Eminye imiklamo ingase idinge izisekelo ezengeziwe noma amathebhu ukuze ubambe i-plywood endaweni ngesikhathi sokusika, kanti ezinye zingadinga ukucatshangelwa okukhethekile kohlobo lokuhlangana olusetshenzisiwe.

Izinkinga Ezivamile & Ukuxazulula Izinkinga

Yehlisa amandla e-laser noma ukhuphule isivinini sokusika; sebenzisa i-masking tape ukuvikela ubuso.

Khulisa amandla e-laser noma unciphise isivinini; qiniseka ukuthi indawo okugxilwe kuyo imiswe kahle.

Khetha i-plywood enomswakama ophansi futhi uyivikele ngokuqinile embhedeni we-laser.

Sebenzisa amandla aphansi ngamaphasi amaningi, noma lungisa izilungiselelo zokusikeka okuhlanzekile.

Ukuze uthole i-laser cut plywood, khetha i-birch, i-basswood, noma i-maple enendawo ebushelelezi, i-low-resin glue, ne-voids encane. Amashidi azacile ahambisana nokuqoshwa, kuyilapho amashidi aminyene adinga amandla engeziwe.

Ekuphetheni

Ukusika i-laser ku-plywood kungaveza ukusikeka kwekhwalithi ephezulu ngokunemba nangesivinini. Kodwa-ke, kunezici ezimbalwa ezibalulekile okufanele zicatshangelwe lapho usebenzisa ukusika i-laser ku-plywood, okuhlanganisa uhlobo lwe-plywood, ubukhulu bezinto ezibonakalayo, isivinini sokusika namandla we-laser, i-lens yokugxila, usizo lomoya, isiqondiso sokusika, nokucatshangelwa komklamo. Ngokucabangela lezi zici, ungafinyelela imiphumela engcono kakhulu ngokusika i-laser ku-plywood.

Kunconywe umshini wokusika i-Wood Laser

| Indawo yokusebenza (W *L) | 80mm * 80mm (3.15'' * 3.15'') |

| Umthombo we-Laser | I-Fiber Laser |

| Laser Amandla | 20W |

| Indawo yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| Laser Amandla | 100W/150W/300W |

| Indawo yokusebenza (W *L) | 1300mm * 2500mm (51” * 98.4”) |

| Umthombo we-Laser | CO2 Glass Laser Tube |

| Laser Amandla | 150W/300W/450W |

Ufuna Ukutshala Imali Emshinini We-Wood Laser?

Isikhathi sokuthumela: Mar-17-2023