Umshini Wokusika Igwebu: Kungani Khetha I-Laser?

Uma kukhulunywa ngomshini wokusika igwebu, umshini wekhilikithi, umsiki wommese, noma ijethi lamanzi yizinketho zokuqala ezingena engqondweni. Kodwa i-laser foam cutter, ubuchwepheshe obusha obusetshenziswa ekusikeni izinto zokufakelwa, kancane kancane iba amandla amakhulu emakethe ngenxa yokunemba okuphezulu kanye nezinzuzo zokusika isivinini esikhulu. Uma ufuna umshini wokusika webhodi le-foam, i-foam core, i-eva foam, i-foam mat, lesi sihloko sizoba umsizi wakho ukuze uhlole futhi ukhethe umshini wokusika we-foam ofanelekile.

Umshini weCricut

Indlela Yokucubungula:Imishini ye-Cricut ingamathuluzi okusika edijithali asebenzisa izindwani ukusika igwebu ngokusekelwe kumiklamo eyenziwe ngekhompyutha. Ziyakwazi ukwenza izinto ezihlukahlukene futhi zingakwazi ukuphatha izinhlobo ezihlukahlukene zegwebu nokuqina.

Izinzuzo:Ukusika okunembile kwemiklamo eyinkimbinkimbi, kulula ukuyisebenzisa ngezifanekiso eziklanywe ngaphambili, ezifanele amaphrojekthi amancane okusika amagwebu.

Imikhawulo:Ikhawulelwe kubukhulu obuthile begwebu, ingase ibe nzima ngezinto eziminyene kakhulu zegwebu.

Umsiki Wommese

Indlela Yokucubungula:Abasiki bommese, abaziwa nangokuthi ama-blade noma ama-oscillating cutters, basebenzisa i-blade ebukhali ukusika igwebu ngokusekelwe kumaphethini ahleliwe. Bangakwazi ukusika imigqa eqondile, amajika, namajamo anemininingwane.

Izinzuzo:Isebenza ngezindlela eziningi ukusika izinhlobo ezahlukene zegwebu nogqinsi, ilungele ukudala izimo eziyinkimbinkimbi namaphethini.

Imikhawulo:Kukhawulelwe ekusikeni kwe-2D, kungase kudinge amaphasi amaningi egwebu eliwugqinsi, ukugqokwa kweblade kungase kuthinte ikhwalithi yokusika ngokuhamba kwesikhathi.

Indiza Yamanzi

Indlela Yokucubungula:Ukusika ijethi yamanzi kusebenzisa umfudlana wamanzi anengcindezi ephezulu exutshwe nezinhlayiya ezilumayo ukuze kunqamuke igwebu. Kuyindlela eguquguqukayo enganqamula izinto eziwugqinsi zegwebu futhi ikhiqize imiphetho ehlanzekile.

Izinzuzo:Inganqamula igwebu eliwugqinsi neliminyene, ikhiqize ukusikeka okuhlanzekile nokunembayo, okuguquguqukayo kwezinhlobo ezihlukahlukene zegwebu nogqinsi.

Imikhawulo:Idinga umshini wokusika indiza yamanzi kanye nezinto ezihuquzelayo, izindleko zokusebenza eziphezulu uma ziqhathaniswa nezinye izindlela, zingase zingabi nembayo njengokusika kwe-laser kwemiklamo eyinkimbinkimbi.

I-Laser Cutter

Indlela Yokucubungula:Imishini yokusika i-laser isebenzisa i-laser beam egxilile ukuze inqamule igwebu ngokufaka umhwamuko endaweni enqunywe kusengaphambili. Banikeza ukunemba okuphezulu futhi bangakha imiklamo eyinkimbinkimbi.

Izinzuzo:Ukusika okunembile nokunemininingwane, kulungele izimo eziyinkimbinkimbi kanye nemininingwane emihle, imfucumfucu yezinto ezibonakalayo, eguquguqukayo ezinhlobonhlobo zegwebu nobukhulu.

Imikhawulo:Ukusethwa kwasekuqaleni nokulinganisa kuyadingeka, izindleko zokuqala eziphezulu uma kuqhathaniswa nezinye izindlela, izinyathelo zokuphepha ezidingekayo ngenxa yokusetshenziswa kwe-laser.

Ukuqhathanisa: yikuphi okungcono ukusika igwebu?

Khuluma mayelanaUkunemba:

Imishini yokusika i-laser inikeza ukunemba okuphezulu kakhulu kanye nemininingwane yemiklamo eyinkimbinkimbi, elandelwa ukusika indiza yamanzi, kuyilapho imishini yeCricut kanye nabasiki bezintambo ezishisayo bafanele ukusikeka okulula.

Khuluma mayelanaUkuhlukahluka:

Imishini yokusika i-laser, ukusika indiza yamanzi, kanye nabasiki bezintambo ezishisayo basebenza ngezindlela eziningi ekuphatheni izinhlobo ezihlukahlukene zegwebu nobukhulu uma kuqhathaniswa nemishini yeCricut.

Khuluma mayelanaUbunkimbinkimbi:

Imishini ye-Cricut ilula ukuyisebenzisa ngezifanekiso eziklanywe ngaphambili, kuyilapho izinqamuli zezintambo ezishisayo zifaneleka ekubunjweni okuyisisekelo, ukusika i-laser, nokusika ijethi yamanzi ukuze kube nokubunjwa okuyinkimbinkimbi nemiklamo.

Khuluma mayelanaIzindleko:

Imishini yeCricut ngokuvamile iyathengeka, kuyilapho imishini yokusika i-laser kanye nokusika indiza yamanzi kudinga ukutshalwa kwezimali okuphezulu kokuqala nokugcinwa njalo.

Khuluma mayelanaUkuphepha:

Imishini yokusika i-laser, ukusika indiza yamanzi, kanye nabasiki bezintambo ezishisayo kudinga izinyathelo zokuphepha ngenxa yokushisa, amanzi anomfutho ophezulu, noma ukusetshenziswa kwe-laser, kuyilapho imishini ye-Cricut ngokuvamile iphephile ukusebenza.

Kafushane, uma unohlelo lwesikhathi eside lokukhiqiza igwebu, futhi ungathanda imikhiqizo eyengeziwe yangokwezifiso nesici, ukuze uthole inani elengeziwe elingeziwe kulokho, isisiki se-laser foam sizoba yisinqumo sakho esifanele. I-foam laser cutter inikeza ukukhiqizwa okunemba okuphezulu ngenkathi ithuthukisa ukusika ukusebenza kahle. Kukhona inzuzo ephakeme futhi engaguquki evela ku-laser cutting foam noma ngabe udinga ukutshala imali emshinini kusenesikhathi. Ukucubungula okuzenzakalelayo kunenzuzo ukuze kunwetshwe isikali sokukhiqiza. Kokunye, uma unezidingo zokucutshungulwa ngokwezifiso nokuguquguqukayo, umsiki we-laser we-foam uyakufanelekela.

▽

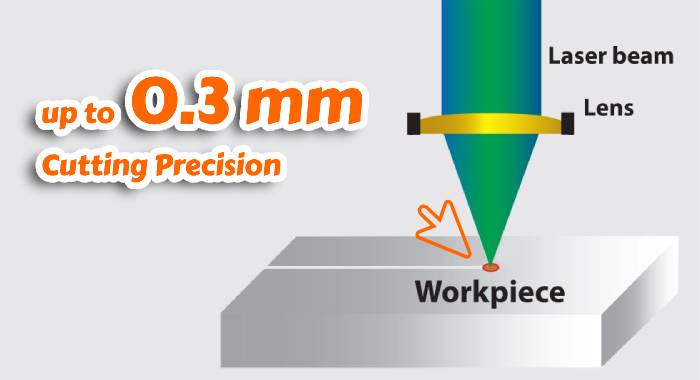

✦ High Cutting Precision

Ngenxa yesistimu yokulawula yedijithali kanye ne-laser beam emihle, abasiki be-laser be-foam banikeza ukunemba okuphezulu nokunemba ekusikeni izinto zegwebu. I-laser beam egxilile ingakha imiklamo eyinkimbinkimbi, imiphetho ebukhali, nemininingwane emihle ngokunemba okukhethekile. Uhlelo lwe-CNC luqinisekisa ukuthembeka kokucubungula ngaphandle kwephutha lezandla.

✦ I-Wide Materials Ukuhlukahluka

Abasiki be-laser be-Foam banemisebenzi eminingi futhi bangakwazi ukuphatha izinhlobo eziningi zegwebu, ukuminyana, nogqinsi. Bangakwazi ukusika amashidi egwebu, amabhlogo, kanye nezakhiwo zegwebu le-3D kalula. Ngaphandle kwezinto zegwebu, i-laser cutter ingakwazi ukuphatha ezinye izinto ezifana nomzwelo, isikhumba, nendwangu. Lokho kuzokunikeza lula kakhulu uma ufuna ukwandisa imboni yakho.

Izinhlobo Zegwebu

Ungakwazi ukusika i-laser

• I-Polyurethane Foam (PU):Lokhu ukukhetha okuvamile kokusikwa kwe-laser ngenxa yokuguquguquka kwayo kanye nokusetshenziswa ezinhlelweni ezifana nokupakishwa, ukufakwa kwe-cushioning, kanye ne-upholstery.

• I-Polystyrene Foam (PS):Amagwebu e-polystyrene anwetshiwe futhi anwetshiwe afanele ukusika i-laser. Zisetshenziswa ekwakhiweni kwe-insulation, ukumodela, nokwenza ubuciko.

• I-Polyethylene Foam (PE):Leli gwebu lisetshenziselwa ukupakisha, ukuguqa, kanye nezinsiza zokuvuselela.

• Igwebu le-Polypropylene (PP):Ivamise ukusetshenziswa embonini yezimoto ukulawula umsindo nokudlidliza.

• Igwebu le-Ethylene-Vinyl Acetate (EVA):Igwebu le-EVA lisetshenziswa kakhulu ukwenza ubuciko, ukupheda, nezicathulo, futhi liyahambisana nokusika nokuqoshwa kwe-laser.

• Igwebu le-Polyvinyl Chloride (PVC):Igwebu le-PVC lisetshenziselwa izimpawu, izibonisi, nokwenza amamodeli futhi lingasikwa nge-laser.

Ubukhulu begwebu

Ungakwazi ukusika i-laser

* Ngogodo lwe-laser olunamandla nolucolisekileyo, umsiki we-laser wegwebu ungadabula igwebu eliwugqinsi kuze kufike ku-30mm.

✦ Imiphetho ehlanzekile futhi evaliwe

Ukusika okuhlanzekile nokushelelayo kuyisici esibalulekile abakhiqizi abahlale bekhathalela ngaso. Ngenxa yamandla okushisa, igwebu lingavalwa ngesikhathi onqenqemeni, okuqinisekisa ukuthi unqenqema aluguquki ngenkathi kugcinwa ukuhlephuka kwe-scrip ekundizeni yonke indawo. Igwebu lokusika i-laser likhiqiza imiphetho ehlanzekile futhi evalekile ngaphandle kokubola noma ukuncibilika, okuholela ekusikekeni okubukeka njengochwepheshe. Lokhu kuqeda isidingo sezinqubo zokuqedela ezengeziwe futhi kuqinisekisa umkhiqizo wokugcina wekhwalithi ephezulu. Lokhu kubalulekile kwezinye izinhlelo zokusebenza ezinezindinganiso eziphakeme ekusikeni ukunemba, njengamathuluzi ezokwelapha, izingxenye zezimboni, ama-gaskets, namadivayisi okuvikela.

✦ Ukusebenza Okuphezulu

Igwebu lokusika i-laser kuyinqubo esheshayo nephumelelayo. I-laser beam inqamula izinto zegwebu ngokushesha futhi ngokunembile, okuvumela ukukhiqizwa okusheshayo kanye nezikhathi zokuguqula. I-MimoWork iklame izinketho zemishini ye-laser ehlukahlukene futhi inokucushwa okuhlukile ongakwazi ukukuthuthukisa, njengamakhanda e-laser akabili, amakhanda e-laser amane, ne-servo motor. Ungakhetha ukucushwa kwe-laser okufanele kanye nezinketho ukuze uthuthukise ukusebenza kahle kwakho kokukhiqiza. Noma yimiphi imibuzo ongayithinta uchwepheshe wethu we-laser ngesikhathi sakho samahhala. Ngaphandle kwalokho, i-foam laser cutter kulula ukuyisebenzisa, ikakhulukazi koqalayo, idinga izindleko zokufunda ezincane. Sizohlinzeka ngezixazululo ezifanele zomshini we-laser kanye nokufakwa okuhambisanayo nokusekelwa komhlahlandlela.>> Khuluma nathi

✦ Ukulahlwa Kwezinto Ezincane

Ngosizo eziphambiliisoftware yokusika i-laser (MIMOCut), yonke inqubo ye-foam yokusika i-laser izothola ilungiselelo lokusika elilungile. Abasiki be-laser be-Foam banciphisa imfucuza ngokuthuthukisa indlela yokusika futhi banciphise ukukhishwa kwempahla eyengeziwe. Lokhu kusebenza kahle kusiza ukonga izindleko nezinsiza, okwenza igwebu lokusika i-laser libe inketho eqhubekayo. Uma unesidingo sokuzalela, sikhonaisofthiwe yokufaka isidleke ngokuzenzakalelayoungakhetha, ukusiza ukwenza lula inqubo yokuzalela, uthuthukise ukusebenza kahle kokucubungula kwakho.

✦ Izimo Eziyinkimbinkimbi Nemiklamo

Abasiki be-laser yegwebu bangakha ubujamo obuyinkimbinkimbi, amaphethini ayinkimbinkimbi, nemiklamo enemininingwane okungaba nzima noma okungenzeki ukuyifeza ngezindlela zokusika zendabuko. Leli khono livula amathuba amasha amaphrojekthi wokudala nezinhlelo zokusebenza.

✦ Non-Contact Cutting

Igwebu lokusika i-laser yinqubo engathinteki, okusho ukuthi isigxobo se-laser asithinti ngokoqobo indawo yegwebu. Lokhu kunciphisa ubungozi bokuguqulwa kwezinto futhi kuqinisekisa ikhwalithi yokusika engaguquki.

✦ Ukwenza ngokwezifiso kanye nokwenza kube ngokwakho

Abasiki be-laser be-Foam bavumela ukwenza ngokwezifiso kanye nokwenza kube ngokwakho imikhiqizo yegwebu. Bangakwazi ukusika amajamo angokwezifiso, amalogo, umbhalo, nezithombe, okuzenze zilungele ukufaka uphawu, izimpawu, ukupakishwa, nezinto zokuphromotha.

I-Foam Laser Cutter edumile

Lapho usunqume ukutshala imali emshinini wokusika we-laser wokukhiqiza igwebu lakho, udinga ukucabangela izinhlobo zezinto zegwebu, usayizi, ukujiya nokunye ukuze uthole umsiki we-laser we-foam onokucushwa okufanele. Isisiki se-laser esiyi-flatbed segwebu sinendawo yokusebenza engu-1300mm * 900mm, siyisisiki se-laser yegwebu lokungena. Emikhiqizweni evamile yegwebu njengamabhokisi amathuluzi, imihlobiso, nemisebenzi yezandla, i-Flatbed Laser Cutter 130 iyisinqumo esidume kakhulu sokusika nokuqoshwa kwegwebu. Usayizi namandla anelisa izidingo eziningi, futhi intengo iyathengeka. Dlula ekwakhiweni, isistimu yekhamera ethuthukisiwe, ithebula lokusebenza ozikhethela lona, nokunye ukulungiselelwa komshini ongazikhetha.

Ukucaciswa komshini

| Indawo yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Isinyathelo Motor Belt Control |

| Ithebula Lokusebenza | I-Honey Comb Working Table noma I-Knife Strip Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Izinketho: Thuthukisa Ukukhiqizwa Kwegwebu

I-Auto Focus

Kungase kudingeke ukuthi usethe ibanga elithile lokugxila kusofthiwe lapho izinto zokusika zingekho flat noma ezinobukhulu obuhlukile. Bese ikhanda le-laser lizokwehla liye phezulu ngokuzenzakalelayo, ligcine ibanga elifanelekile lokugxila endaweni ebonakalayo.

I-Servo Motor

I-servomotor iyi-servomotor evaliwe esebenzisa impendulo yendawo ukuze ilawule ukunyakaza kwayo kanye nendawo yokugcina.

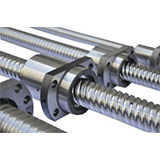

I-Ball Screw

Ngokuphambene nezikulufu zokuhola ezivamile, izikulufu zebhola zivamise ukuba nkulu, ngenxa yesidingo sokuba nendlela yokuzungeza kabusha amabhola. Isikulufu sebhola siqinisekisa isivinini esikhulu kanye nokusikwa kwe-laser ngokunemba okuphezulu.

Izicelo Ezibanzi

Funda kabanzi mayelana ne-Foam Laser Cutter

Uma unamapheshana amakhulu okusika noma igwebu eligoqekayo, umshini wokusika we-foam laser 160 ukufanele. I-Flatbed Laser Cutter 160 ingumshini onefomethi enkulu. Nge-auto feeder kanye nethebula le-conveyor, ungakwazi ukufeza izinto zokugoqa zokuzicubungula ngokuzenzakalela. 1600mm *1000mm yendawo yokusebenza ifanele iningi le-yoga mat, umata wasolwandle, umcamelo wezihlalo, i-gasket yezimboni nokunye. Amakhanda e-laser amaningi ayakhethwa ukuze kuthuthukiswe ukukhiqiza. Umklamo ovaliwe ovela emshinini wokusika we-laser wendwangu uqinisekisa ukuphepha kokusetshenziswa kwe-laser. Inkinobho yokumisa izimo eziphuthumayo, ukukhanya kwesignali yezimo eziphuthumayo, nazo zonke izingxenye zikagesi zifakwe ngokuqinile ngokuvumelana nezindinganiso ze-CE.

Ukucaciswa komshini

| Indawo yokusebenza (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Ukudlulisa Ibhande & Isinyathelo Motor Drive |

| Ithebula Lokusebenza | I-Honey Comb Working Table / I-Cnife Strip Ithebula Lokusebenza / Ithebula Lokusebenza Lokuthutha |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

Izinketho: Thuthukisa Ukukhiqizwa Kwegwebu

Amakhanda we-Laser Dual

Ngendlela elula neyomnotho kakhulu yokusheshisa ukusebenza kahle kwakho kokukhiqiza ukukhweza amakhanda e-laser amaningi endaweni eyodwa bese usike iphethini efanayo ngesikhathi esisodwa. Lokhu akuthathi indawo eyengeziwe noma umsebenzi.

Uma uzama ukusika imiklamo eminingi ehlukene futhi ufuna ukonga impahla ngezinga elikhulu, iI-Nesting Softwarekuzoba yisinqumo esihle kuwe.

II-Auto feederkuhlanganiswe ne-Conveyor Table yisisombululo esifanele sochungechunge nokukhiqizwa ngobuningi. Ithutha izinto eziguquguqukayo (indwangu isikhathi esiningi) ukusuka kumqulu kuya kunqubo yokusika ohlelweni lwe-laser.

Izicelo Ezibanzi

Qala Ukukhiqiza Kwakho Kwegwebu nge-Flatbed Laser Cutter 160!

• Ungakwazi yini ukusika igwebu nge-laser cutter?

Yebo, igwebu lingasikwa nge-laser cutter. Igwebu lokusika i-laser kuyinqubo evamile futhi ephumelelayo enikeza izinzuzo ezimbalwa, okuhlanganisa ukunemba, ukuguquguquka, nokusebenza kahle. I-laser egxilile ishunqisa noma incibilikise impahla yegwebu ngendlela enqunywe kusengaphambili, okuholela ekusikeni okuhlanzekile nokunembayo okunamaphethelo avaliwe.

• Ungakwazi yini ukusika i-eva foam nge-laser?

Yebo, igwebu le-EVA (ethylene-vinyl acetate) lingasikwa nge-laser ngempumelelo. Igwebu le-EVA liyinto eguquguqukayo evame ukusetshenziswa ezimbonini ezahlukahlukene ezifana nezicathulo, ukupakisha, imisebenzi yezandla, kanye ne-cosplay. Igwebu le-Laser lokusika i-EVA linikeza izinzuzo ezimbalwa, okuhlanganisa ukusikeka okunembile, imiphetho ehlanzekile, kanye nekhono lokudala imiklamo nemilo eyinkimbinkimbi. I-laser egxilile ishisa igwebu ngendlela enqunywe kusengaphambili, okuholela ekusikeni okunembile nokunemininingwane ngaphandle kokubola noma ukuncibilika.

• Indlela yokusika igwebu nge-laser?

1. Lungiselela umshini wokusika i-Laser:

Qinisekisa ukuthi umshini wokusika we-laser usethelwe kahle futhi ulinganiselwe ukusika igwebu. Hlola ukugxila kwe-laser beam futhi ukulungise uma kunesidingo ukuze uthole ukusebenza okuhle kokusika.

2. Khetha Izilungiselelo Ezilungile:

Khetha amandla e-laser afanele, isivinini sokusika, nezilungiselelo zokuvama okusekelwe ohlotsheni nogqinsi lwento yegwebu oyisikayo. Bheka imanuwali yomshini noma thintana nomkhiqizi ukuze uthole izilungiselelo ezinconyiwe.

3. Lungiselela I-Foam Material:

Beka impahla yegwebu phezu kombhede wokusika nge-laser futhi uyivikele endaweni usebenzisa izinsimbi noma itafula le-vacuum ukuvimbela ukunyakaza ngesikhathi sokusika.

4. Qala Inqubo Yokusika I-Laser:

Layisha ifayela lokusika ku-software yomshini wokusika we-laser bese ubeka isigxobo se-laser lapho uqala khona indlela yokusika.

Qalisa inqubo yokusika, futhi ugongolo lwe-laser luzolandela indlela enqunywe kusengaphambili, ukusika izinto zegwebu endleleni.

Thola Izinzuzo Nezinzuzo Ku-Foam Laser Cutter, Khuluma nathi ukuze ufunde kabanzi

Izindaba Ezihlobene

Noma yimiphi imibuzo mayelana ne-Laser Cutting Foam?

Isikhathi sokuthumela: May-09-2024