Unomhlahlandlela Womshini Wokushisela We-Laser Wokuqandisa

Umhlahlandlela Ophelele Wokuqandisa Imishini Yokushisela I-Laser

Ubuchwepheshe bokushisela nge-laser bushintsha ukukhiqiza ngokunemba nokusebenza kahle kwawo.

Kodwa-ke, ukusebenza ezindaweni ezibandayo kungadala izinselele emishinini yokushisela i-laser.

Lo mhlahlandlela uhlinzeka ngolwazi olubalulekile mayelana namazinga okushisa okusebenza, izinyathelo zokuphepha, nezindlela zokunqanda ukuqhwa ukuze ugcine imishini yakho yokushisela i-laser isebenza kahle.

Uhlu Lokuqukethwe:

I-Handheld Laser Welding Operating Temperature Izidingo

Esinye sezici ezibucayi ekusebenzeni kahle komshini wokushisela we-laser ophathwayo yizinga lokushisa elisebenzayo.

Uma i-laser ivezwe ezindaweni ezingezansi5°C, izinkinga eziningi zingavela:

•Ukulimala Emzimbeni: Ezimweni ezimbi kakhulu, amapayipi angaphakathi esistimu yokupholisa amanzi angase akhubazeke noma aqhume, okuholela ekulungiseni okubizayo kanye nesikhathi sokuphumula.

•Ukwehluleka Kokusebenza: Emazingeni okushisa aphansi, amasekhethi amanzi angaphakathi kanye namadivayisi abonakalayo angase ahluleke ukusebenza ngendlela evamile. Lokhu kungaholela ekusebenzeni okungahambisani noma ukuvala shaqa okuphelele.

Ibanga Lezinga Lokushisa Elilungile

Ukuqinisekisa ukusebenza kahle, kubalulekile ukugcina amazinga okushisa alandelayo:

•Indawo yokusebenzaUkushisa: 5°C kuya ku-40°C

•Ukupholisa Amanzi OkushisaUkushisa: 25°C kuya ku-29°C

Ukweqa le mikhawulo yamazinga okushisa kungase kuthinte ukuzinza kokuphuma kwe-laser futhi kungase kulimaze ne-laser ngokwayo.

Ukugcina okokusebenza kwakho ngaphakathi kwale mingcele kubalulekile empilweni ende nokusebenza.

Ngifuna Ukwazi Uma Ezinye Izimo Zezulu

Ithinta Imishini Ye-Laser?

Izinyathelo zokuphepha zomshini wokushisisa we-Laser Weld Anti-freeze

Ukuze uvikele umshini wakho wokushisela we-laser ezindabeni ezihlobene nokubanda, cabanga ukusebenzisa lezi zinyathelo zokuphepha ezilandelayo:

1. Ukulawula izinga lokushisa

•Faka Izinhlelo Zokulawula Isimo Sezulu: Sebenzisa isimo somoya noma indawo yokushisisa ukuze ugcine indawo yokusebenza ingaphezu kuka-5°C. Lokhu kuqinisekisa ukuthi okokusebenza kwe-laser kungasebenza ngokujwayelekile ngaphandle kokudinga izinyathelo ezikhethekile zokunqanda ukuqhwa.

2. Ukuphathwa Kwe-Chiller

•Ukusebenza Okuqhubekayo: Gcina i-chiller isebenza 24/7. Isistimu yokupholisa ejikelezayo ivimbela amanzi ukuthi angaqhwa, ngisho noma izinga lokushisa langaphakathi lehla.

•Gada Izimo Zangaphakathi: Uma izinga lokushisa langaphakathi liphansi, qinisekisa ukuthi izinyathelo eziyisisekelo zokunqanda ukuqhwa zisendaweni. Ukugcina amanzi okupholisa egeleza kubalulekile.

3. Isitoreji Sesikhathi Eside

•Khipha Amanzi Ngesikhathi Sokuphumula: Uma okokusebenza kwe-laser kungeke kusetshenziselwe isikhathi eside noma phakathi nokuphela kukagesi, kubalulekile ukukhipha amanzi ku-chiller. Gcina iyunithi endaweni engaphezu kuka-5°C ukuze uvimbele noma yiziphi izinkinga ezibanda.

•Izixwayiso Zeholide: Ngamaholide noma lapho uhlelo lokupholisa lungakwazi ukusebenza ngokuqhubekayo, khumbula ukukhipha amanzi ohlelweni lokupholisa. Lesi sinyathelo esilula singakusindisa ekulimaleni okukhulu.

Thola Ukuthi I-Laser Welding

Ifanele Isifunda Sakho Nemboni

Izinto Ezisetshenziswayo Zisebenzisa I-Antifrize Njengokupholisa

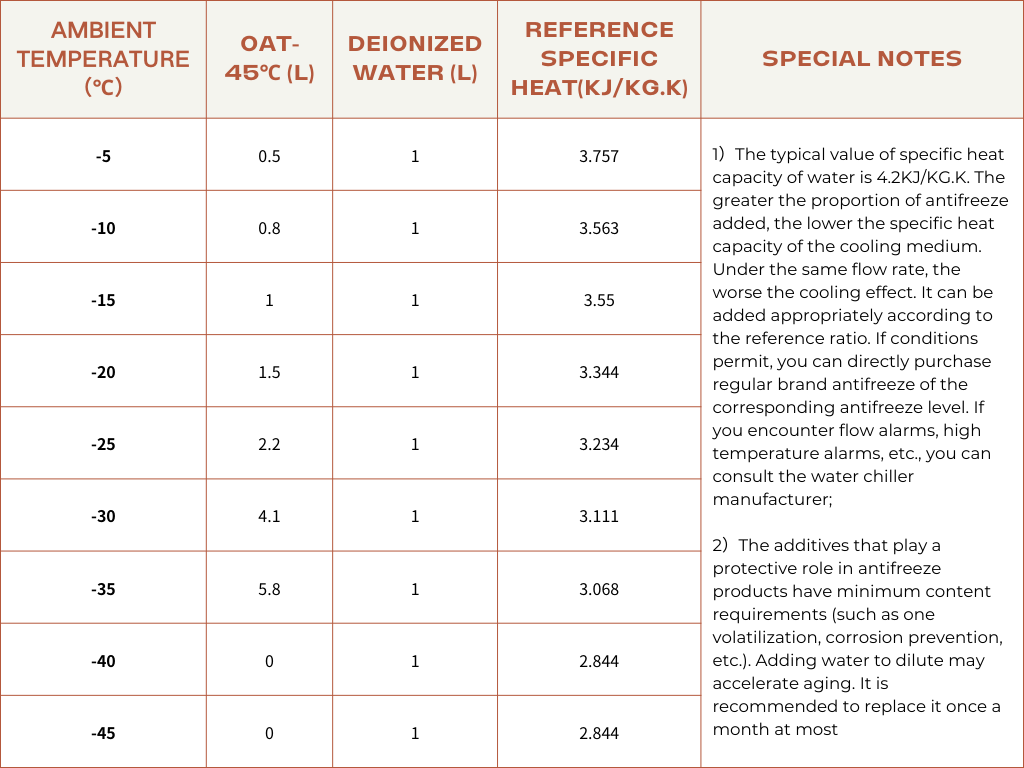

Ithebula lomhlahlandlela we-Coolant Addition Ratio:

AMACEBISO:I-OAT-45 ℃isho isipholile se-Organic Acid Technology esakhelwe ukusebenza ngempumelelo emazingeni okushisa aphansi, ehle aze afike ku-45 degrees Celsius.

Lolu hlobo lokupholisa luhlinzeka ngokuvikeleka okuphezulu emakhazeni, ekugqwaleni, nasekukaleni kumasistimu okupholisa ezimoto nawemboni.

Noma iyiphi i-antifreeze ayikwazi ukufaka esikhundleni samanzi akhishwe ngokuphelele futhi ayikwazi ukusetshenziswa isikhathi eside unyaka wonke.

Ngemuva kobusika, amapayipi kufanele ahlanzwe ngamanzi akhishwe i-deionized noma amanzi ahlanzekile, futhi amanzi ahlanzekile noma amanzi ahlanzekile kufanele asetshenziswe futhi njengesipholisa.

Ngesikhathi esifanayo, ngamaholide afana neholide Lomkhosi Wasentwasahlobo noma phakathi nokunqamuka kukagesi isikhathi eside, sicela ukhiphe amanzi kumapayipi ahlobene ne-laser kanye nomshini wokupholisa amanzi bese ufaka amanzi okupholisa esikhundleni sawo; uma i-antifreeze isetshenziselwa ukupholisa isikhathi eside, ingabangela umonakalo wokugqwala ohlelweni lokupholisa nge-laser.

04 Khipha okokupholisa okokusebenza Esimweni sezulu esibanda kakhulu ebusika, wonke amanzi okupholisa ku-laser, ekhanda elikhipha i-laser nomshini wokupholisa amanzi kufanele akhishwe ahlanzeke ukuze kuvikelwe ngempumelelo isethi yamapayipi okupholisa amanzi nezinye izingxenye ezihlobene.

I-Handheld Laser Weld: Yini Ongayilindela ngo-2024

I-laser welding ephathwa ngesandla inikeza ukunemba nokuphatheka kokujoyina okubalulekile.

Ilungele izindawo eziqinile futhi inciphisa ukuhlanekezela okushisayo.

Zitholele amathiphu namasu emiphumela emihle esihlokweni sethu sakamuva!

Izinto Ezi-5 Mayelana Ne-Laser Welding (Okuphuthele)

I-laser welding iyindlela enembile futhi esheshayo enezinzuzo ezimbalwa ezibalulekile:

Inciphisa izindawo ezithinteke ukushisa, isebenza ngezinto ezihlukahlukene, idinga ukuhlanzwa okuncane, futhi ikhuphule umkhiqizo.

Thola ukuthi lezi zinzuzo ziguqula kanjani ukukhiqiza!

I-High-Capacity & Wattage yezinhlelo zokusebenza zokushisela ezihlukahlukene

Umshini wokushisela we-laser ongu-2000W ubonakala ngosayizi womshini omncane kodwa ikhwalithi yokushisela ekhazimulayo.

Umthombo we-fiber laser ezinzile kanye nekhebula lefayibha exhunyiwe inikeza ukulethwa kwe-laser beam ephephile futhi engaguquki.

Ngamandla aphezulu, i-laser welding keyhole iphelele futhi yenza i-welding joint firmer iqine ngisho nangensimbi ewugqinsi.

Ukuphatheka kokuvumelana nezimo

Ngokubukeka komshini ohlangene futhi omncane, umshini we-laser welder ophathwayo ufakwe isibhamu se-laser esiphathwayo esinyakazayo esingasindi futhi esilungele ukusetshenziswa kwe-multi-laser welding kunoma iyiphi i-engeli nangaphezulu.

Izinhlobo ezihlukahlukene zokuzikhethela ze-laser welder nozzle kanye nezinhlelo zokuphakela izintambo ezizenzakalelayo zenza ukusebenza kwe-laser welding kube lula futhi lokho kube nobungane kwabaqalayo.

I-high-speed laser welding kukhulisa kakhulu ukusebenza kahle kwakho kokukhiqiza kanye nokuphumayo kuyilapho kunika amandla umphumela omuhle kakhulu we-laser welding.

Ukuhlukahluka kwe-laser welding?

Umshini Wokushisela we-Laser ophathwa ngesandla kusuka ku-1000w kuya ku-3000w

Uma uyijabulele le vidiyo, kungani ungacabangiubhalisela Isiteshi sethu se-YouTube?

Izicelo Ezihlobene Ongase Uzithande:

Konke Okuthengiwe Kufanele Kwaziswe Kahle

Singasiza Ngolwazi Oluningiliziwe kanye Nokubonisana!

Isikhathi sokuthumela: Jan-03-2025