Izinketho Ezincane, Ukuthuthukiswa Okukhulu

Isitolo Sempahla Ephelele Yezinketho Zakho Ze-Laser

Ukusebenza okuphezulu kanye nekhwalithi ye-premium ekukhiqizeni kukhathazwa kakhulu ngabakhiqizi. Ngokubambisana nemikhiqizo ethenjwayo ehamba phambili embonini, i-MimoWork iyakwazi ukunikeza izinketho ze-laser ezifanele kakhulu ngokusebenza okungcono kakhulu kwamakhasimende ethu ukuze kuthuthukiswe izimo zokukhiqiza futhi kuzuzwe ukugeleza kokukhiqiza okushelelayo nokuphumelelayo. I-MimoWork inikeza izinketho ezimbalwa ezimboza isofthiwe, i-hardware, kanye namadivayisi emishini ashintshwayo we-laser cutter, i-laser engraver kanye nomshini we-galvo laser. Lezi zinketho ze-laser ezinemisebenzi eminingi zandisa ukunwebeka kanye nokuguquguquka ezindleleni zokucubungula nokusebenza. Benza lula ukulungiselela kusengaphambili, bandise ukugeleza kokusika kanye nokwelashwa kwangemva kokwelashwa.

Ngaphandle kwalokho, ukuphepha kokusebenza kanye nokuphathwa kwemfucuza (ukuvikelwa kwemvelo) yizinto ezivelele okufanele zishiwo. Ukulandela ukulungiswa nokuthuthukiswa kokukhiqiza kwakho, kuyadingeka ukuthi izinketho zibuyekezwe ngesikhathi futhi zishintshwe ngendlela evumelana nezimo, okungenza umehluko omkhulu ekuhambeni komsebenzi wakho wesikhathi esizayo. Okokugcina, izinketho zomshini we-laser ezenziwe ngezifiso zingafezeka ngokuya ngezidingo zakho ezithile.

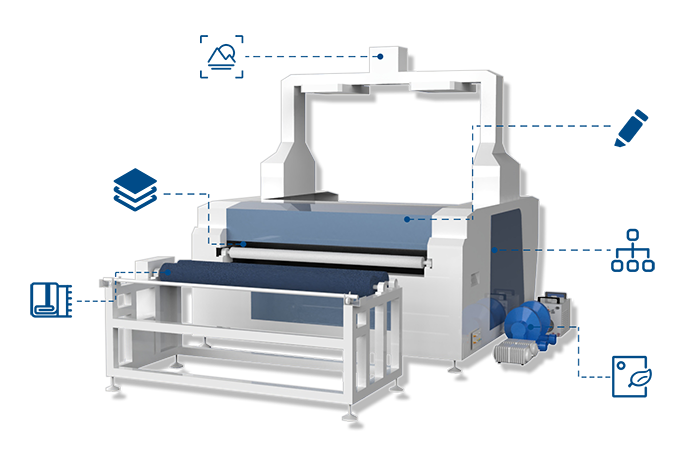

Ukusekelwa kwedijithali kokusika kwe-laser okulula nokunembile

●Yenza kube lula ukusika kwakho kwe-laser nokuqopha ukugeleza

●Isistimu yokulawula idijithali inciphisa iphutha

●Ukusebenza okuzenzakalelayo konga umsebenzi nesikhathi

Ukusika nokuqopha nge-laser okunembile, ukwakheka kwengcaca nokuzalela ngokuzenzakalela, kanye nohlelo olwengeziwe lokubeka i-laser kusekelwa isofthiwe ye-laser emiswe kahle.I-MimoCUT, I-MimoNest, I-MimoPROTOTYPE, I-MimoPROJECTIONikusiza ukuthi ubone ukulawula okudijithali nokuzenzakalelayo ngenkathi uqinisekisa ukusika kwe-laser okulungile nokusebenzayo.

Auto Nesting Software for Laser Cutting

Thola izinto eziyisisekelo zokusebenzisa isofthiwe yokuzalela ukuze uthuthukise izinqubo zakho zokukhiqiza, kungakhathaliseki ukuthi uhileleke endwangu yokusika i-laser, isikhumba, i-acrylic, noma ukhuni. Ividiyo ihlinzeka ngemininingwane ezicini ezishintshayo eziphezulu nezonga izindleko ze-autonest, ikakhulukazi kusofthiwe ye-laser cut nesting.

Zitholele ukuthi isofthiwe yokuzenzela isidleke ingathuthukisa kanjani ngokuphawulekayo ukusebenza kahle nokukhishwayo kokukhiqiza, ikwenze kube utshalomali olubalulekile nolungabizi kakhulu lokukhiqiza ngobuningi. Funda izimfihlo zokukhulisa ukonga okubalulekile nge-software ye-laser enesting futhi ukhuphule amandla akho okukhiqiza.

Umsizi wezinto ezinembile zokusika amaphethini we-laser

●Ukuqashelwa okunembile kusho ukusika okunembile

●I-automation ephezulu yokulungiswa okulula nokuhlolwa

●Ifanele izinto ezinephethini

●Iphutha elincane ngokuchibiyela amaphutha okuphrinta

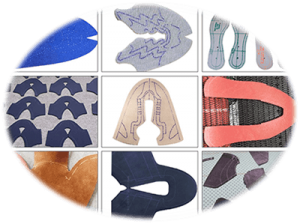

Iyini isistimu ye-optical recognitiong? Kuzinto ezinephethini, ama-Optical Recognition Systems avela ku-MimoWork ayadingeka ukuze ubone ukuqashelwa okunembile kanye nokuma kokusika okunembile kohlaka lwempahla. Imikhiqizo ye-dayi-sublimation efana nejezi, izingubo zezemidlalo, izingubo zokubhukuda, izesekeli zezingubo ezifana ne-embroidery patch, isichibi sokuphrinta, inombolo ye-tackle twill, ilebula, nezinye izinhlelo zokusebenza ezidinga ukuqashelwa ngokuvamile zisikwa i-contour nge-laser cutter nge.Ukuqashelwa kwe-Coutour, Ukuma kwekhamera ye-CCD, futhiUkufanisa Isifanekiso.

Ikhamera Laser Cutting Machine

Ikhamera ye-laser cutter, umngane wakho ofanele wokusika ngokunemba kwezingubo zemidlalo ezingaphansi kwe-sublimated. Lo mshini we-Cutting-Edge udlula izindwangu eziphrintiwe ezisika i-laser kanye nezingubo ezisebenzayo ngezindlela ezithuthukile nezizenzakalelayo. Ifakwe ikhamera nesithwebuli, umshini wethu wokusika i-laser unikeza ukusebenza kahle okungenakuqhathaniswa kanye nesivuno esikhulu. Ividiyo ehambisana naso ikhombisa amandla alesi sisiki se-laser esizenzakalelayo esidizayinelwe isembatho.

Ngamakhanda e-laser e-Y-axis amabili, ifinyelela ukusebenza kahle okungenakuqhathaniswa, okuyenza ibe yisixazululo sezindwangu zokusika i-laser sublimation, okuhlanganisa namajezi okusika i-laser. Phakamisa amakhono akho okusika ngokusebenza kahle nangokunemba kwesisiki sekhamera yethu yakamuva ye-laser.

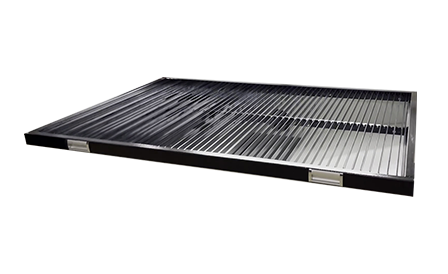

●Isiqinisekiso sokucubungula esiqinile esinetafula le-laser elilinganayo neliqinile

●I-modular futhi ingathatha indawo yezinto ezihlukahlukene

●Imisebenzi enwetshiwe ukuze kuthuthukiswe ukusebenza kahle

●Ilondoloza isikhala ngefomethi eyenziwe ngokwezifiso

Amafomethi wezinto ezihlukile, isisindo segremu, ukujiya, kanye nokuminyana, kanye nokuthi iyagobeka noma iqinile, lezi zimo zezinto ezibonakalayo zinquma ukukhetha okuhlukile kwetafula lokusika i-laser. Ngaphandle kwalokho, ihlose ukusebenza kahle okuphezulu kanye nokwelashwa kwempahla okusesimweni esihle, iMimoWork isungule i-Working Table eminingana ukuze ithuthukise ukusika nokuqopha nge-laser kanye nokugeleza okuphelele kokusebenza kwezidingo zamakhasimende ahlukahlukene.

●Ukondla okuqhubekayo nokusika kwe-laser

●Ukuguquguquka kwezinto ezihlukahlukene

●Ukonga izindleko zabasebenzi kanye nesikhathi

●Kwengezwe amadivayisi azenzakalelayo

●Okukhiphayo okulungisekayo kokuphakelayo

Ifanele izinto zokugoqa ezinesisindo esihlukahlukene, ukujiya, idigri ebushelelezi, ukunwebeka, kanye nefomethi, Amasistimu Okondla anezilungiselelo ezihlukene ahlinzeka ngokusekela nokondla okuqhubekayo kwezinto ngesivinini esinikeziwe, okuqinisekisa ukusika kahle ngokuthambile, ukushelela, nokushuba okumaphakathi. Futhi isebenza kahle kakhulu futhi yonga isikhathi kuma-Feeding Systems axhumene neIthebula le-Conveyor.

I-Laser Cutter enethebula lesandiso

Yembula indlela esebenza kahle kakhulu neyonga isikhathi yokusika indwangu ngesisiki se-CO2 laser esinethebula lesandiso. Ithebula lesandiso lisiza ukuqoqwa kwezingcezu eziqediwe, okuthuthukisa kakhulu izindlela zokonga isikhathi. Uma ubheke ukuthuthukisa i-textile laser cutter yakho futhi wandise umbhede we-laser ngaphandle kokwelula isabelomali sakho, ividiyo iphakamisa ukuhlola isisiki se-laser esinamakhanda amabili ngethebula lesandiso.

Ngale kokusebenza kahle, lesi sisiki se-laser sendwangu yezimboni sihamba phambili ekuphatheni izindwangu ezinde kakhulu, sisenze silungele amaphethini amade kunetafula elisebenzayo. Phakamisa amakhono akho okusika indwangu ngokusebenza kahle okuphezulu kanye namathuba andiwe.

●Izinto ezinembile zilebula ngokulawula kwedijithali

●Ilungele ukufinyeza ukuthunga okulandelayo noma ukuqondanisa

●Izinto ezihlukahlukene zingamakwa kuzo

●Itholakala ngemibala ehlukene kanye nokwakheka

Usebenzisa amapeni omaka nezinketho ze-inkjet, ungamaka izingcezu zokusebenza ukuze wenze ukukhiqizwa okulandelayo kube lula. Ikakhulukazi endabeni yokuthunga amamaki (ukusika) emkhakheni wokukhiqiza izindwangu. Isibonelo, ekusetshenzisweni kwendwangu yokusika yokuhlunga, ukukhetha ipeni lokumaka noma i-ink-jet ukumaka imigqa yokuqondanisa ngqo esiqeshini, konga isikhathi nobunzima ekusebenzeni okulandelayo.

I-CO2 Laser Cut & Mark Fabric

Izwa amakhono athuthukile we-1810 fabric laser cutter, umshini wokusika indwangu yemboni ye-laser osezingeni eliphezulu oklanyelwe ukuguqula inqubo yokuthunga indwangu.

Lo mshini omusha ufakwe idivayisi ye-inkjet elandela ngaphandle komthungo inhloko yokusika i-laser, ukumaka nokusika izingcezu zendwangu ngephasi eyodwa. Ividiyo ibonisa ubulula obulethwa yilokhu kunqubo yokuthunga indwangu, enikeza ukusebenza kahle nokunemba.

●Isiqinisekiso sendawo yokusebenza ephephile

●Vikela izinto ekungcolisweni nasekulinyazweni

Isixazululo esisebenzayo sokungenisa umoya singasiza umuntu axazulule uthuli nentuthu ekhathazayo kuyilapho kunciphisa ukuphazamiseka ekukhiqizeni. Ihlanganiswe ne-laser enhaust blower, i-laser fume Extraction emiswe eceleni noma phansi kwesisiki se-laser iqinisekisa ukwelashwa kwegesi engcolile futhi ikusiza ukuthi wakhe indawo yokusebenza ephephile nehlanzekile.