Laser Amathebula

Amatafula okusebenza nge-laser aklanyelwe izinto ezikahle zokondla nokuthutha ngesikhathi sokusika, ukuqopha, ukubhoboza nokumaka nge-laser. I-MimoWork inikeza amatafula alandelayo we-cnc laser ukuthuthukisa ukukhiqiza kwakho. Khetha isudi ngokuya ngesidingo sakho, isicelo, impahla kanye nendawo yokusebenza.

Inqubo yokulayisha kanye nokukhipha izinto ezivela etafuleni lokusika i-laser ingaba umsebenzi ongasebenzi kahle.

Njengoba kunikezwe itafula elilodwa lokusika, umshini kufanele ume ngokuphelele kuze kube yilapho lezi zinqubo seziqediwe. Ngalesi sikhathi sokungenzi lutho, uchitha isikhathi esiningi nemali. Ukuze kuxazululwe le nkinga futhi kwandiswe umkhiqizo jikelele, i-MimoWork incoma ithebula le-shuttle ukususa isikhathi sokuphumula phakathi kokuphakela nokusika, kusheshiswe yonke inqubo yokusika i-laser.

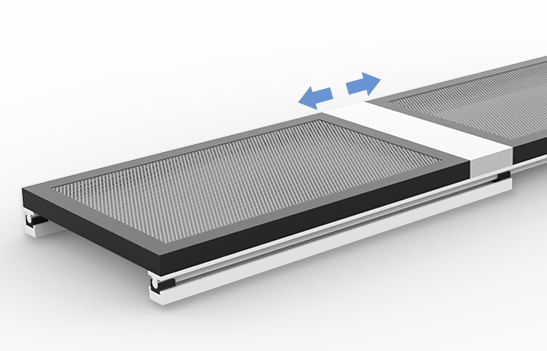

Ithebula le-shuttle, elibizwa nangokuthi i-pallet changer, lakhiwe ngomklamo wokudlula ukuze lithuthwe ngezindlela ezimbili. Ukuze kube lula ukulayishwa nokukhishwa kwezinto ezinganciphisa noma ziqede ukuphumula futhi zihlangabezane nokusika kwakho kwezinto ezithile, siklame osayizi abahlukahlukene ukuze bafanele wonke usayizi owodwa wemishini yokusika i-MimoWork laser.

Izici Eziyinhloko:

Ifanele izinto zeshidi eziguqukayo neziqinile

| Izinzuzo zamathebula e-pass-through shuttle | Ukungalungi kwamatafula wokudlula |

| Zonke izindawo zokusebenza zimi ngobude obufanayo, ngakho-ke akukho ukulungisa okudingekayo ku-axis ye-Z | Yengeza endaweni yonyawo lwesistimu ye-laser jikelele ngenxa yesikhala esengeziwe esidingekayo ezinhlangothini zombili zomshini |

| Isakhiwo esizinzile, esihlala isikhathi eside futhi sithembekile, amaphutha ambalwa kunamanye amatafula e-shuttle | |

| Ukukhiqiza okufanayo ngentengo ethengekayo | |

| Ezokuthutha ezizinzile nezingadlidlizi | |

| Ukulayisha nokucubungula kungenziwa kanyekanye |

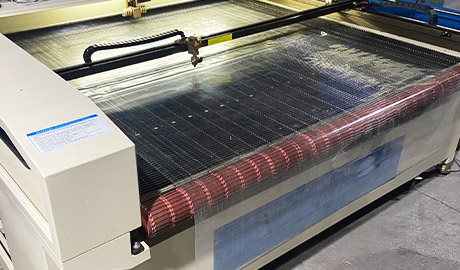

Ithebula le-Conveyor for Laser Cutting Machine

Izici Eziyinhloko:

• Akukho ukwelula indwangu

• Ukulawula unqenqema okuzenzakalelayo

• Osayizi abenziwe ngokwezifiso ukuze bahlangabezane nazo zonke izidingo, basekele ifomethi enkulu

Izinzuzo Zohlelo Lwethebula Le-Conveyor:

• Ukwehliswa kwezindleko

Ngosizo lwesistimu yokuthutha, ukusika okuzenzakalelayo nokuqhubekayo kuthuthukisa kakhulu ukusebenza kahle kokukhiqiza. Ngaleso sikhathi, kusetshenziswa isikhathi esincane nomsebenzi, kunciphisa izindleko zokukhiqiza.

• Ukukhiqiza okuphezulu

Ukukhiqiza komuntu kunomkhawulo, ngakho ukwethula ithebula le-conveyor esikhundleni sezinga elilandelayo lakho ekukhuliseni amavolumu okukhiqiza. Ihambisana nei-auto-feeder, Ithebula le-MimoWork conveyor linika amandla ukuphakela nokusika ukuxhumana okungenamthungo nokuzishintshanisa ukuze kusebenze kahle kakhulu.

• Ukunemba nokuphindaphinda

Njengoba isici esiyinhloko sokwehluleka ekukhiqizeni futhi siyisici somuntu - ukufaka esikhundleni somsebenzi wezandla ngomshini ozenzakalelayo onembile, ohleliwe onethebula lokudlulisa kuzonikeza imiphumela enembe kakhudlwana.

• Ukwanda kokuphepha

Ukuze wakhe indawo yokusebenza ephephile, ithebula lokuthutha linweba indawo yokusebenza engaphandle lapho ukubhekwa noma ukuqapha kuphephe ngokuphelele.

Izinyosi Laser Umbhede for Laser Machine

Ithebula lokusebenza liqanjwe ngesakhiwo salo esifana nekhekheba lezinyosi. Iklanyelwe ukuhambisana nawo wonke usayizi wemishini yokusika i-MimoWork laser.Ikhekheba lezinyosi lokusika nokuqopha nge-laser liyatholakala.

I-aluminium foil ivumela i-laser beam ukuthi idlule ngokuhlanzekile ezintweni ozicubungulayo futhi inciphisa ukubonakaliswa okungaphansi ekushiseni ingemuva lento futhi ivikela ngokuphawulekayo ikhanda le-laser ekubeni lonakaliswe.

Umbhede we-laser wezinyosi uvumela ukungena komoya okulula kokushisa, uthuli, nentuthu ngesikhathi senqubo yokusika i-laser.

Izici Eziyinhloko:

• Ifanele izinhlelo zokusebenza ezidinga ukuboniswa kwengemuva okuncane kanye nokucaba okuphezulu

• Ithebula elisebenzayo lekhekheba lezinyosi eliqinile, elizinzile, neliqinile lingasekela izinto ezisindayo

• Umzimba wensimbi osezingeni eliphezulu ukusiza ukuthi ulungise izinto zakho ngozibuthe

Ithebula le-Knife Strip for Laser Cutting Machine

Ithebula le-Cnife strip, elibizwa nangokuthi ithebula lokusika le-aluminium slat yakhelwe ukusekela izinto kanye nokugcina indawo eyisicaba. Leli thebula le-laser cutter lilungele ukusika izinto ezijiyile (ugqinsi lwama-8 mm) kanye nezingxenye ezibanzi kuno-100 mm.

Ikakhulukazi okokusika ezintweni eziwugqinsi lapho ungathanda ukugwema ukubhampa kwe-laser. Amabha aqondile nawo avumela ukugeleza kwe-exhaust engcono kakhulu ngenkathi usika. I-Lamellas ingafakwa ngabanye, ngenxa yalokho, ithebula le-laser lingalungiswa ngokuvumelana nesicelo ngasinye ngasinye.

Izici Eziyinhloko:

• Ukucushwa okulula, uhla olubanzi lwezinhlelo zokusebenza, ukusebenza okulula

• Ifanele i-laser cut substrates njenge-acrylic, ukhuni, ipulasitiki, nokunye okuqinile

Noma yimiphi imibuzo mayelana nosayizi wombhede we-laser cutter, izinto ezihambisana namatafula we-laser nokunye

Silapha ngenxa yakho!

Amanye amathebula eLaser ajwayelekile okusika nokuqopha nge-Laser

Ithebula le-Laser Vacuum

Ithebula le-laser cutter vacuum lilungisa izinto ezahlukahlukene etafuleni lokusebenza lisebenzisa i-vacuum elula. Lokhu kuqinisekisa ukugxila okulungile phezu kwendawo yonke futhi ngenxa yalokho imiphumela engcono yokuqoshwa iqinisekisiwe. Kuhlanganiswe nefeni yokukhipha umoya, ukusakazwa komoya okumunca kungaphephula insalela kanye nesiqephu sento engashintshi. Ngaphezu kwalokho, kunciphisa umzamo wokubamba ohambisana nokunyuswa kwemishini.

Ithebula le-vacuum liyithebula elilungile lezinto ezilula nezilula, njengephepha, ama-foil, namafilimu ngokuvamile angalali phansi.

Ithebula le-Ferromagnetic

Ukwakhiwa kwe-ferromagnetic kuvumela ukukhuphuka kwezinto ezincanyana njengephepha, amafilimu noma ama-foil anamagnets ukuqinisekisa indawo elinganayo futhi eyisicaba. Ngisho nokusebenza kubalulekile ukuze kuzuzwe imiphumela emihle yokuqoshwa kwe-laser nokumaka izinhlelo zokusebenza.

Ithebula le-Acrylic Cutting Grid

Kubandakanya ithebula lokusika le-laser elinegridi, igridi ekhethekile ye-laser engraver ivimbela ukubuyiswa emuva. Ngakho-ke ilungele ukusika ama-acrylic, ama-laminates, noma amafilimu epulasitiki anezingxenye ezincane kuno-100 mm, njengoba lezi zihlala endaweni eyisicaba ngemva kokusikwa.

Ithebula le-Acrylic Slat Cutting

Ithebula le-laser slats elinama-acrylic lamellas livimbela ukubukeka ngesikhathi sokusika. Leli thebula lisetshenziselwa ikakhulukazi ukusika izinto eziwugqinsi (ubukhulu obuyi-8 mm) kanye nezingxenye ezibanzi kuno-100 mm. Inombolo yamaphuzu asekelayo ingancishiswa ngokususa amanye ama-lamellas ngabanye, kuye ngomsebenzi.

Imfundo Eyengeziwe

I-MimoWork iphakamisa ukuthi ⇨

Ukuze uqaphele umoya omncane kanye nemfucuza eqeda amandla, phansi noma ohlangothinii-exhaust blowerafakwe ukuze enze igesi, intuthu kanye nezinsalela kudlule etafuleni lokusebenza, ukuvikela izinto zokwenziwa ekulimaleni. Ngezinhlobo ezahlukene zomshini we-laser, ukucushwa nokuhlangana kwe-itafula lokusebenza, idivayisi yokungenisa umoyafuthii-fume extractorzihlukile. Isiphakamiso se-laser sochwepheshe sizokunikeza isiqinisekiso esithembekile ekukhiqizeni. I-MimoWork ilapha ukuze ilinde uphenyo lwakho!