3D Laser Carving

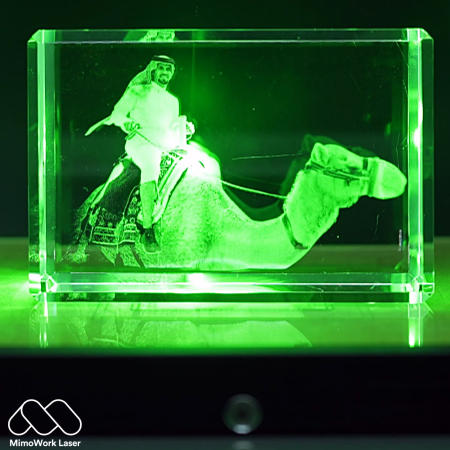

Imagine capturing a complex design, a cherished memory, or a breathtaking landscape within a crystal, forever preserved in its sparkling depths. This is the magic of 3D laser carving, a revolutionary technique that utilizes focused laser beams to etch intricate details from the surface into the crystals, creating stunning three-dimensional masterpieces.

What is 3D Laser Carving

3D laser carving is a sophisticated process that employs a high-powered laser to remove material from a crystal's inside precisely.

The laser beam, guided by a computer program, moves across the crystal, vaporizing tiny portions of the material, creating intricate patterns and designs.

This technique allows for the creation of incredibly detailed and complex 3D sculptures within the crystal itself, revealing its internal beauty and adding depth to the artwork.

What Materials can be 3D Laser Carved?

3D Laser Carving of Tree Painting

While various materials can be laser carved, crystals are particularly well-suited for this technique due to their unique properties:

Transparency: Crystals allow light to pass through them, enhancing the visibility of the carved design and creating captivating optical effects.

Hardness: Crystals are durable and resistant to scratching, ensuring the longevity of the artwork.

Variety: The wide range of crystal types, from clear quartz to vibrant amethyst, offers a diverse palette for artistic expression.

Popular Choices for 3D Laser Carving Include:

Quartz: Known for its clarity and brilliance, quartz is a versatile material for intricate carvings.

Amethyst: With its captivating purple hue, amethyst adds a touch of elegance and mystique to 3D laser carvings.

Citrine: This golden-yellow crystal brings warmth and vibrancy to the artwork, making it a popular choice for decorative pieces.

Want to Know More about 3D Laser Carving?

We can Help!

The Process of 3D Laser Carving

The process of 3D laser carving crystal involves several steps:

Design: The artist creates a digital 3D model of the desired design, carefully considering the crystal's shape and size.

Preparation: The crystal is cleaned and prepared for carving, ensuring a smooth and pristine surface.

Video Demonstration: 3D Laser Carving

How to Choose Glass Engraving Machine

Laser Carving: The crystal is placed on a specialized platform within the laser machine. The laser beam, guided by the computer program, meticulously follows the 3D model, removing material layer by layer to create the desired design.

Polishing: After carving, the crystal is polished to enhance its shine and reveal the intricate details of the artwork.

Finishing: The final step may involve adding a protective coating to the crystal to preserve its beauty and prevent damage.

3D laser carving crystal is a captivating art form that combines advanced technology with artistic vision. It allows for the creation of stunning and unique pieces that capture the beauty of light and the artistry of human creativity.

How to Improve 3D Laser Carving Results

While 3D laser carving technology is impressive, achieving optimal results requires careful attention to detail and a few key considerations:

The Process of 3D Laser Carving

Crystal Quality: Choosing high-quality crystals with minimal inclusions or imperfections will ensure a smoother carving process and a more aesthetically pleasing final product.

Laser Power and Speed: Adjusting the laser power and speed settings based on the crystal type and design complexity is crucial for precise carving and preventing damage to the crystal.

Design Optimization: Simplifying intricate designs and avoiding sharp angles can improve carving accuracy and reduce the risk of breakage.

Post-Processing: Polishing and cleaning the crystal after carving enhances its clarity and reveals the intricate details of the artwork.

Best 3D Laser Carving Machines

The One & Only Solution you will ever need for 3D Laser Carving, packed to the brim with the latest technologies with different combinations to meet your ideal budgets.

The Power of the Laser in the Palm of your Hand.

Supports 6 Different Configurations

From Small Scale Hobbyist to Large Scale Production

Repeated Location Accuracy at <10μm

Surgical Precision for 3D Laser Carving

3D Crystal Laser Engraving Machine (3D Etching inside Glass)

Different from huge laser machines in the traditional perception, the mini 3D laser engraving machine has a compact structure and small size which is like a desktop laser engraver.

Small figure but has a powerful energy.

Compact Laser Body for 3D Laser Carving

Shock-Proof & Safer for Beginners

Fast Crystal Engraving up to 3600 points/second

Great Compatibility in Design

While 3D laser carving technology is impressive, achieving optimal results requires careful attention to detail and a few key considerations:

1. Can you Laser Engrave a Crystal?

Yes, laser engraving is a common technique for crystals. It involves using a laser to mark the surface of the crystal, creating a permanent design. While laser engraving doesn't create the 3D depth of carving, it can still produce beautiful and intricate patterns.

2. Can you Carve Stone with a Laser?

Yes, laser carving is a versatile technique that can be used to carve various types of stone, including crystals. The process involves using a high-powered laser to remove material from the stone's surface, creating intricate designs and sculptures.

3. Can you Laser Engrave Gemstones?

Yes, laser engraving is a popular method for personalizing gemstones. It allows for the creation of intricate designs, logos, or even text on the surface of the gemstone. The process is generally safe for most gemstones, but it's important to choose a reputable engraver who understands the specific properties of each gemstone.

4. How does 3D Laser Crystal Engraving Work?

3D laser crystal engraving utilizes a high-powered laser beam to remove material from the crystal's surface, creating a three-dimensional design. The laser beam is guided by a computer program that translates a 3D model into precise laser movements.

The laser vaporizes tiny portions of the crystal, creating intricate details and depth within the artwork. The process is similar to carving stone, but the laser's precision and control allow for the creation of incredibly detailed and complex 3D sculptures within the crystal itself.