Laser Cutting Burlap Fabric

Introduction

What is Burlap Fabric?

Burlap is a durable, loosely woven fabric derived from natural plant fibers, primarily jute.

Known for its rough texture and earthy appearance, it is widely used in agriculture, packaging, crafts, and sustainable decor.

Its breathability and biodegradability make it a favorite for eco-friendly projects.

Burlap Features

Eco-Friendly: Biodegradable and made from renewable plant fibers.

Texture: Natural rustic feel, ideal for organic-themed designs.

Breathability: Permeable structure suitable for planters and storage.

Heat Tolerance: Withstands moderate laser heat when settings are adjusted.

Versatility: Adaptable for crafts, home decor, and event styling.

Burlap Reusable Bag

History and Innovations

Historical Background

Burlap has been used for centuries, originating in regions where jute and hemp were abundant.

Traditionally employed for sacks, ropes, and agricultural purposes, it gained modern popularity in DIY crafts and sustainable design due to its natural appeal.

Future Trends

Reinforced Blends: Combining jute with cotton or polyester for added durability.

Dyed Variants: Eco-friendly dyes to expand color options while retaining sustainability.

Industrial Applications: Laser-cut burlap in biodegradable packaging and architectural models.

Types

Natural Jute Burlap: Unbleached, coarse texture for rustic projects.

Blended Burlap: Mixed with cotton or synthetic fibers for smoother finishes.

Colored Burlap: Dyed with natural pigments for decorative uses.

Refined Burlap: Softened and tightly woven for apparel accents.

Material Comparison

| Fabric Type | Texture | Durability | Cost |

| Natural Jute | Coarse | Moderate | Low |

| Blended Burlap | Medium | High | Moderate |

| Colored Burlap | Slightly Smooth | Moderate | Moderate |

| Refined Burlap | Soft | Low-Moderate | Premium |

Burlap Applications

Burlap Table Runner

Burlap Wedding Favors

Burlap Gift Wraps

Burlap Plant Pot Cover

Home Decor

Laser-cut table runners, lampshades, and wall art.

Event Styling

Customized banners, wedding favors, and centerpieces.

Eco-Packaging

Precision-cut tags, gift wraps, and reusable bags.

Gardening

Plant pot covers and seed mats with engraved patterns.

Functional Characteristics

Edge Sealing: Laser heat naturally seals edges to minimize fraying.

Design Flexibility: Suitable for bold, geometric cuts due to open weave.

Eco-Compatibility: Ideal for projects emphasizing sustainability.

Mechanical Properties

Tensile Strength: Moderate; varies with fiber blend.

Flexibility: High in natural jute; reduced in refined blends.

Heat Resistance: Requires lower laser power to avoid scorching.

How to Laser Cut Burlap Fabric?

CO₂ lasers are ideal for burlap, offering a balance of speed and detail. They provide a natural edge finish with minimal fraying and sealed edges.

Their efficiency makes them suitable for large-scale projects like event decor, while their precision allows for intricate patterns even on the coarse texture of burlap.

Step-by-Step Process

1. Preparation: Flatten fabric to avoid uneven cuts.

2. Settings: Start with low power to prevent burning.

3. Cutting: Use air assist to remove debris and ensure clean edges.

4. Post-Processing: Brush off loose fibers and inspect edges.

Burlap Lamb Shade

Related Videos

Auto Feeding Laser Cutting Machine

The auto-feeding laser cutting machine offers efficient and precise fabric cutting, unlocking creativity for textile and garment designs.

It handles various fabrics with ease, including long and roll materials.The 1610 CO₂ laser cutter provides straight cutting, automatic feeding, and processing, boosting production efficiency.

Ideal for beginners, fashion designers, and manufacturers, it enables customized designs and flexible production, revolutionizing how you bring your ideas to life.

How to Cut Fabric with a Laser Cutter

Learn how to laser cut fabric in our video, featuring a guide for denim and jeans. The fabric laser cutter is fast and flexible for both custom designs and mass production.

Polyester and denim are ideal for laser cutting—discover more suitable materials!

Any Question to Laser Cutting Burlap Fabric?

Let Us Know and Offer Further Advice and Solutions for You!

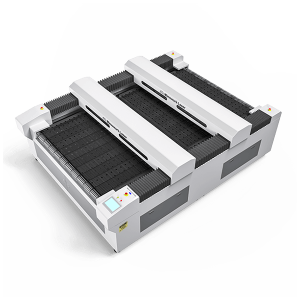

Recommended Burlap Laser Cutting Machine

At MimoWork, we specialize in cutting-edge laser cutting technology for textile production, with a particular focus on pioneering innovations in Burlap solutions.

Our advanced techniques tackle common industry challenges, ensuring impeccable outcomes for clients across the globe.

Laser Power: 100W/150W/300W

Working Area (W * L):1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power: 100W/150W/300W

Working Area (W * L): 1800mm * 1000mm (70.9” * 39.3 ”)

Laser Power: 150W/300W/450W

Working Area (W * L): 1600mm * 3000mm (62.9’’ *118’’)

FAQs

No. Proper settings preserve its structural integrity while sealing edges.

Burlap is commonly used as a backing material for linoleum, carpets, rugs, and in sacks for grains and vegetables.

Historically, it was originally exported from India for many of the same reasons it is valued today.

Despite its coarse texture, burlap is highly practical due to its durability and breathability.

Burlap fabric is generally more affordable than many synthetic fabrics and is among the least expensive textiles globally.

However, artisanal forms of jute can be costly. Typically, burlap costs between $10 and $80 per yard.