Ceramic Insulator (Laser Cleaning)

Cleaning ceramic insulators with a handheld laser cleaner can be an effective method, especially for removing stubborn contaminants without damaging the surface. However, If you are cleaning ceramic insulators on a smaller scale, we will also provide some recommendations and tips.

How to Clean Ceramic Insulator?

With a Laser Cleaner & some Traditional Cleaning Methods

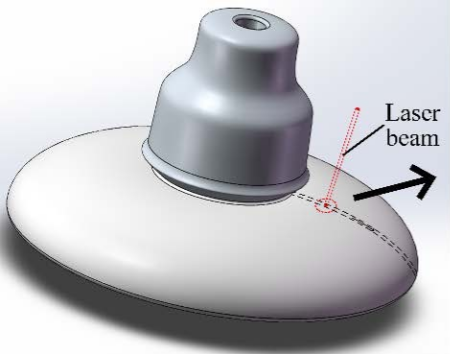

The Laser Cleaning Process of Ceramic Insulators

If you are cleaning ceramic insulation with pulse laser cleaning, here are the steps and some tips:

Before Pulse Laser Cleaning:

Ensure that the laser cleaner is set up in a safe environment, wear safety goggles, gloves, and a face shield to protect against laser exposure and debris. Check for any cracks or damage in the ceramic. Do not proceed if the insulator is compromised.

Set the laser cleaner to the appropriate settings for ceramic materials. (A laser power of 90-100 W and a scanning speed in the range of 6000-12000 mm/s can effectively remove substrate surface contamination and will not cause damage to the substrate.)

During Pulse Laser Cleaning:

Before cleaning the entire insulator, perform a test on a small, inconspicuous area to ensure that the settings are suitable and effective.

Hold the laser cleaner at the recommended distance from the surface. Move the laser in a controlled manner across the area, keeping it steady and at the proper speed to avoid overheating the ceramic.

Continuously check the surface as you clean it to ensure no damage is occurring. Adjust settings if necessary based on the cleaning effectiveness.

Do not overlap the laser path too much to prevent excessive heat buildup.

After Pulse Laser Cleaning:

Once cleaning is complete, inspect the insulator for cleanliness and any signs of damage.

Allow the insulator to cool down if it is heated during the cleaning process. Ensure the insulator is dry and free of debris before placing it back in service.

Regular cleaning can help maintain the insulator’s performance and extend its lifespan.

For Traditional Cleaning Methods:

Ensure the insulator is NOT connected to any electrical source. Wear safety goggles and gloves if necessary.

Check for cracks or damage. Do not attempt to clean if the insulator is compromised.

Mix a few drops of mild detergent with warm water in a bucket.

Use a soft brush or cloth to gently remove loose dust and debris from the surface.

Soak a soft sponge in the soapy water, wring it out, and gently wipe the insulator. Avoid excessive scrubbing.

For stubborn dirt, use a soft toothbrush dipped in the soapy solution to gently scrub the affected areas.

Rinse the insulator with clean water to remove any soap residue. Ensure no water enters any crevices.

Allow the insulator to air dry completely before reconnecting it or placing it back in service.

Do NOT use abrasive materials that could scratch the ceramic.

Avoid extreme temperatures when cleaning, as this can crack the ceramic.

Can you Use Rubbing Alcohol to Clean Ceramic?

Yes, you Can Use Rubbing Alcohol to Clean Ceramic Insulators

Same as the steps provided above, using rubbing alcohol to clean ceramic insulators can be counted as a traditional cleaning method.

Additionally, using rubbing alcohol to clean ceramic-based surfaces effectively removes oils and contaminants. Rubbing alcohol can help eliminate bacteria and other microorganisms.

It dries quickly, reducing moisture exposure, compared to other cleaning solutions

Are Laser Cleaners Worth it?

If you Frequently Clean Ceramic Insulators at a Large Scale, then yes

Laser cleaners can be a viable option for cleaning ceramic insulators, Laser cleaning allows for targeted removal of contaminants without damaging the underlying material.

This method requires NO chemicals, making it a more sustainable choice. Lasers can clean surfaces quickly, reducing downtime compared to traditional methods.

The process generates less waste, as materials are vaporized rather than scraped off. Suitable for various contaminants, including dust, grime, and oxidation.

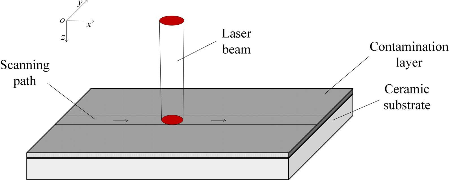

The Process for Laser Cleaning Ceramic Insulator

Does Laser Cleaning Remove Material?

No, when Performed in a Controlled Manner

The laser energy is absorbed by contaminants on the surface, which can include rust, paint, or dirt. This energy causes the contaminants to vaporize.

The intensity and focus of the laser can be adjusted to minimize the impact on the underlying material.

The goal is to preserve the integrity of the substrate, such as ceramic.

Operators can control the depth of cleaning by adjusting the laser's settings, ensuring that only the unwanted material is removed.

Laser cleaning is designed to selectively remove contaminants without significantly affecting the base material.

With proper technique and equipment settings, damage to the underlying surface can be minimized.

A Batch of Ceramic Surface Before Laser Cleaning

Want to Know about How to Clean Ceramic Insulator

The Right Way?

Is Laser Cleaning Safe?

What is Laser Cleaning & How it Works?

Just like any other tools, Laser cleaning can be safe when proper precautions and protocols are followed.

Operator Safety

Operators should wear appropriate safety gear, including laser safety goggles, gloves, and protective clothing.

Proper training is essential for operators to understand how to use the equipment safely.

Environmental Safety

Laser cleaning does NOT use harmful chemicals, making it more environmentally friendly.

The process generates less waste, reducing environmental impact.

Workplace Safety

Ensure the cleaning area is secured to prevent unauthorized access during operation.

Adequate ventilation is important to remove any fumes or particles generated during the cleaning process.

Equipment Safety

Regular maintenance of the laser equipment is necessary to ensure safe operation.

Have clear emergency procedures in place in case of accidents or equipment malfunction.

What is the Best Thing to Clean Ceramic with?

Pulsed Laser Cleaner (100W, 200W, 300W, 400W)

Pulsed fiber laser cleaners are particularly well-suited for cleaning delicate, sensitive, or thermally vulnerable surfaces, where the precise and controlled nature of the pulsed laser is essential for effective and damage-free cleaning.

Laser Power: 100-500W

Pulse Length Modulation: 10-350ns

Fiber Cable Length: 3-10m

Wavelength: 1064nm

Laser Source: Pulsed Fiber Laser