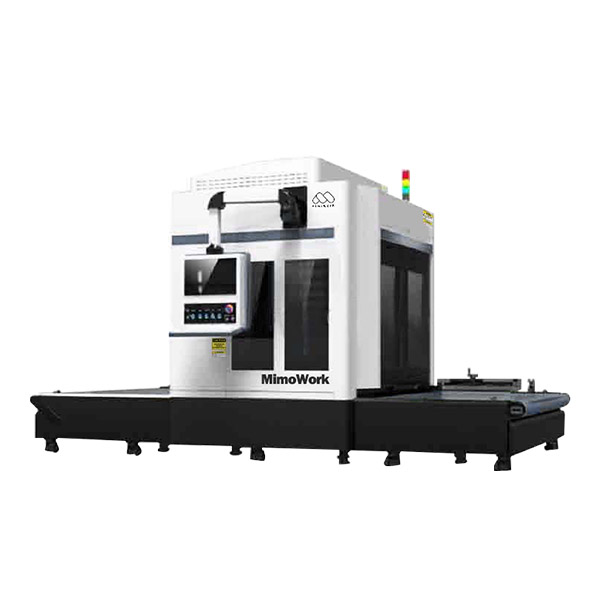

China Wholesale 4×4 Fiber Laser Cutter Factories Pricelist - 200W Laser Cutter – MimoWork Laser

China Wholesale 4×4 Fiber Laser Cutter Factories Pricelist - 200W Laser Cutter – MimoWork Laser Detail:

The 200W Laser Cutter – Cutting, Engraving, Everything

Technical Data

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 200W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* More sizes of laser working table are customized

* Higher Laser Power Output Upgrades Available

We Don’t Settle for Mediocre Results, Neither Should You

Versatility Packed with Possibilities

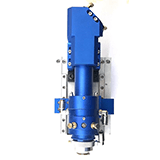

Ball & Screw

The ball screw is a highly precise mechanical linear actuator that smoothly converts rotational motion into linear motion with minimal friction. It consists of a threaded shaft with a helical raceway that guides ball bearings, which act as a precise screw. Its exceptional ability to handle high thrust loads with minimal internal friction makes it an ideal choice for high-precision applications. The ball assembly serves as the nut, while the threaded shaft serves as the screw. Unlike traditional lead screws, ball screws tend to be bulkier due to the need for a mechanism to recirculate the balls. With the ball screw technology, you can achieve high-speed and high-precision laser cutting, ensuring that your production output is of the highest quality.

Servo Motors

A servomotor is a precise and responsive closed-loop servomechanism that relies on position feedback to control its motion and final position. The servomotor is paired with a position encoder, providing accurate and responsive position and speed feedback. The motor is controlled by an input signal that represents the commanded position for the output shaft. By comparing the measured position to the command position, the controller generates an error signal that causes the motor to rotate and move the output shaft into the correct position. As the positions converge, the error signal decreases until the motor stops. By utilizing servomotors, laser cutting and engraving are enhanced with higher speeds and greater precision, resulting in remarkable cuts and engravings.

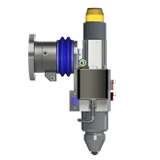

Mixed Laser Head

The mixed laser head, or metal non-metallic laser cutting head, is a crucial component of any metal and non-metal combined laser cutting machine. It allows for the cutting of both metal and non-metal materials, offering unparalleled versatility. This laser head is equipped with a Z-Axis transmission part that tracks the focus position by moving up and down. Thanks to its double drawer structure, it’s possible to use two different focus lenses for cutting materials of varying thicknesses without the need for any focus distance or beam alignment adjustments. This makes it incredibly easy to use and enhances cutting flexibility. Plus, you can use different assist gas to tailor it to different cutting jobs, making it a highly adaptable tool for any production environment.

Upgradable Laser Tube

With this cutting-edge upgrade, you can boost your machine’s laser power output up to an impressive 300W, allowing you to cut even thicker and tougher materials with ease. Our Upgradable Laser Tube is designed to be easy to install, meaning you can quickly and easily upgrade your existing laser cutting machine without the need for complicated and time-consuming modifications. This makes it an ideal solution for businesses that are looking to increase their production capabilities and expand their range of services. By upgrading to our Upgradable Laser Tube, you’ll be able to cut through a wide variety of materials with precision and accuracy. Whether you’re working with wood, acrylic, metal, or other solid materials, our laser tube is up to the task. The high power output means that even the thickest materials can be cut with ease, giving you greater flexibility and versatility in your work.

Auto Focus

This laser head is specially designed for metal cutting, but can also be used for other materials. With its advanced software, you can set a precise focus distance to ensure consistent cutting quality, even when dealing with non-flat or differently sized materials. The laser head features an automated Z-axis transmission that enables it to move up and down, maintaining the same height and focus distance you’ve set in the software. This technology ensures that every cut is made with precision and accuracy, regardless of the material’s thickness or shape. Say goodbye to inconsistent cutting and hello to the perfect results every time!

Need More Information about this Machine’s Extensive Upgrade Options?

▶ FYI: This 200W Laser Cutter is suitable to cut and engrave on solid materials such as acrylic and wood. Honeycomb working table and knife strip cutting table can carry the materials and help to reach best the cutting effect without dust and fume that can be sucked into and purified.

<a href="https://www.mimowork.com/working-table/" title=">> Discover laser cutting tables” target=”_blank”>

>> Discover laser cutting tables

<a href="https://www.mimowork.com/fume-extractor/" title=">> Discover laser fume extractor” target=”_blank”>

>> Discover laser fume extractor

Video of Laser Cutting & Engraving Acylic (PMMA)

Acrylic materials require precise and uniform heat energy to be melted correctly, and that’s where laser power comes into play. The right laser power can guarantee that heat energy penetrates uniformly through the material, resulting in precise cuts and unique artwork with a beautifully polished edge. Experience the incredible results of laser cutting and engraving on acrylic and see your creations come to life with unparalleled precision and finesse.

Fields of Application

Laser Cutting for Your Industry

Laser Photo Engraving

Crystal surface and exquisite engraving details

✔ Bringing about more economical and environment-friendly manufacturing process

✔ Customized patterns can be engraved whether for pixel and vector graphic files

✔ Quick response to market from samples to large-lot production

Advertising & Gifts

Unique advantages of laser cutting signs & decorations

✔ Clean and smooth edges with thermal melting when processing

✔ No limitation on shape, size, and pattern realizes flexible customization

✔ Customized laser tables meet requirements for varieties of materials formats

Common Materials and Applications

Materials: Acrylic, Wood, Paper, Plastic, Glass, MDF, Plywood, Laminates, Leather, and other Non-metal Materials

Applications: Signs(signage), Crafts, Jewelry, Key chains, Arts, Awards, Trophies, Gifts, etc.

View more materials

View more applications

Experience Precision Cutting and Intricate Designs

At the Push of a Button

Product detail pictures:

Related Product Guide:

Our goal is to satisfy our customers by offering golden service, good price and high quality for China Wholesale 4×4 Fiber Laser Cutter Factories Pricelist - 200W Laser Cutter – MimoWork Laser , The product will supply to all over the world, such as: Estonia , Swansea , Morocco , Our staffs are adhering to the Integrity-based and Interactive Development spirit, and the tenet of First-class Quality with Excellent Service. According to the needs of every customer, we give customized & personalised services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

We have been looking for a professional and responsible supplier, and now we find it.