China Wholesale 4×8 Laser Cutter Factories Pricelist - Laser Wire Stripper – MimoWork Laser

China Wholesale 4×8 Laser Cutter Factories Pricelist - Laser Wire Stripper – MimoWork Laser Detail:

Mechanical Support from Laser Wire Stripper

◼ Small Size

The desktop model with compact and small in size.

◼ Automation Working Flow

One-key operation with the automatic computer-control system, saving time and labor.

◼ High-Speed Stripping

Stripping wire simultaneously by up and down dual laser heads brings high efficiency and convenience for stripping.

Technical Data

| Working Area (W * L) | 200mm * 50mm |

| Laser Power | US Synrad 30W RF Metal Laser Tube |

| Cutting Speed | 0-6000mm/s |

| Positioning Precision | within 0.02mm |

| Repeat Precision | within 0.02mm |

| Dimension | 600 * 900 * 700mm |

| Cooling Method | air cooling |

Why choose laser to strip wires?

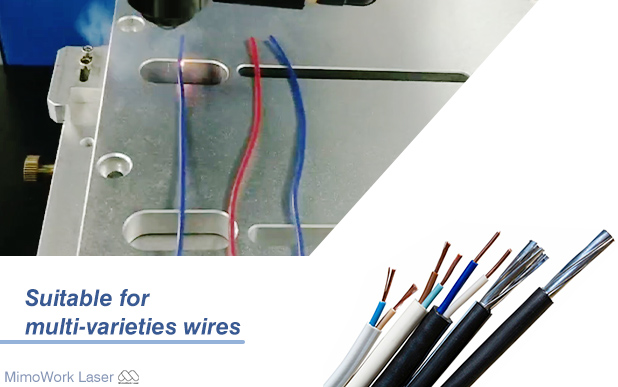

Principle of laser wire stripping

During the laser wire stripping process, the energy of radiation emitted by the laser is absorbed strongly by the insulating material. As the laser penetrates the insulation, it vaporizes the material through to the conductor. However, the conductor strongly reflects the radiation at the CO2 laser wavelength and is therefore unaffected by the laser beam. Because the metallic conductor is essentially a mirror at the wavelength of the laser, the process is effective “self-terminating”, that is the laser vaporizes all of the insulating material down to the conductor and then stops, so no process control is required to prevent damage to the conductor.

Advantages from laser wire stripping

✔ Clean and thorough stripping for insulation

✔ No damage to the core conductor

Comparatively, conventional wire-stripping tools make physical contact with the conductor, which can damage the wire and slow down processing speed.

✔ High repetition – steady quality

Video Glance of laser wire stripping

Suitable materials

Fluoropolymers (PTFE, ETFE, PFA), PTFE /Teflon®, Silicone, PVC, Kapton®, Mylar®, Kynar®, Fiberglass, ML, Nylon, Polyurethane, Formvar®, Polyester, Polyesterimide, Epoxy, Enameled coatings, DVDF, ETFE /Tefzel®, Milene, Polyethylene, Polyimide, PVDF and other hard, soft or high-temperature material…

Fields of Application

Common applications

(medical electronics, aerospace, consumer electronics and automotive)

Learn more about laser wire stripper price, operation guide

Add yourself to the list!

Product detail pictures:

Related Product Guide:

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for China Wholesale 4×8 Laser Cutter Factories Pricelist - Laser Wire Stripper – MimoWork Laser , The product will supply to all over the world, such as: UAE , Madras , Belize , As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.