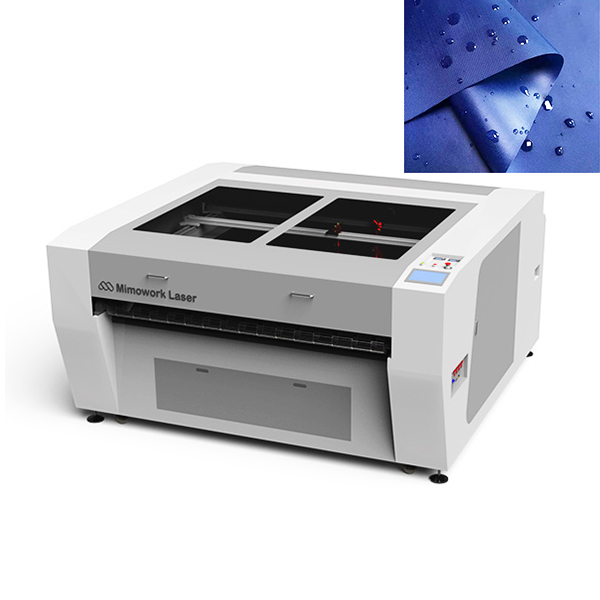

China Wholesale Camera Laser Cutter Manufacturers Suppliers - Flatbed Laser Cutter 160L – MimoWork Laser

China Wholesale Camera Laser Cutter Manufacturers Suppliers - Flatbed Laser Cutter 160L – MimoWork Laser Detail:

Advantages of Industrial Laser Cutter for Fabric

A Giant Leap in Productivity

Technical Data

| Working Area (W * L) | 1600mm * 3000mm (62.9’’ *118’’) |

| Max Material Width | 1600mm (62.9’’) |

| Software | Offline Software |

| Laser Power | 150W/300W/500W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Rack & Pinion Transmission and Servo Motor Driven |

| Working Table | Conveyor Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

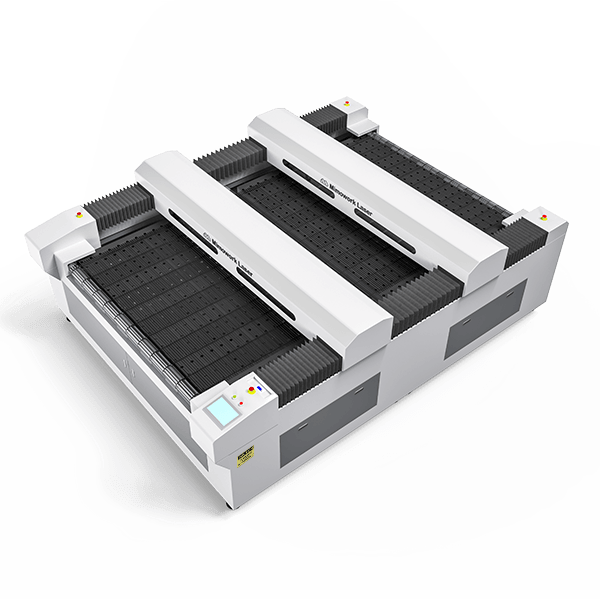

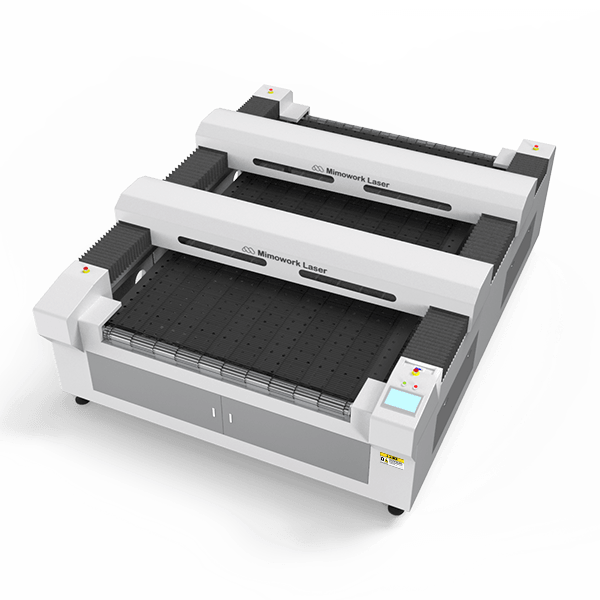

* Two independent laser gantries are available to double your efficiency.

(Upgrade Power for your industrial fabric laser cutting machine, garment laser cutting machine)

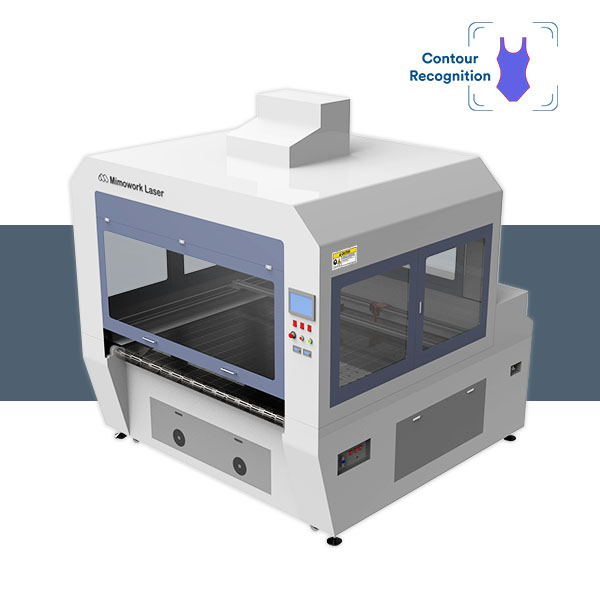

R&D for Fabric Laser Cutting

Auto Feeder

Auto Feeder is a feeding unit that runs synchronously with the laser cutting machine. The feeder will convey the roll materials to the cutting table after you put the rolls on the feeder. Feeding speed can be set according to your cutting speed. A sensor is equipped to ensure perfect material positioning and minimize errors. The feeder is able to attach different shaft diameters of rolls. The pneumatic roller can adapt textiles with various tension and thickness. This unit helps you to realize a completely automatic cutting process.

Vacuum Suction

The Vacuum Suction lies under the cutting table. Through the small and intensive holes on the surface of the cutting table, the air ‘fastens’ the material on the table. The vacuum table does not get in the way of the laser beam while cutting. On the contrary, together with the powerful exhaust fan, it enhances the effect of smoke & dust prevention during cutting.

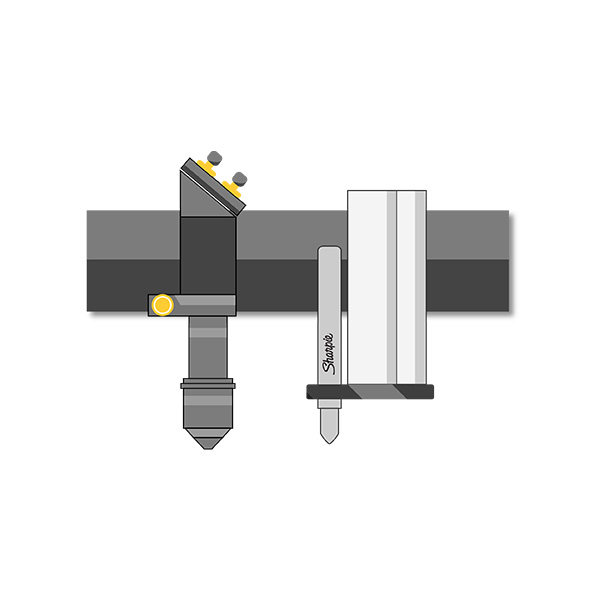

Marker Pen – Option

For most manufacturers, especially for processing technical textiles, pieces need to be sewn right after the cutting process. Thanks to the Marker Pen, you can make marks such as the serial number of the product, the size of the product, the manufacture date of the product, etc to increase overall efficiency. You can choose different colors as per your needs.

CO2 RF Laser Source – Option

Combines power, excellent beam quality, and nearly square wave pulses (9.2 / 10.4 / 10.6μm) for high processing efficiency and speed. With small heat-affected zone, plus compact, fully sealed, slab discharge construction for enhanced reliability. For some special industrial fabrics, RF Metal Laser Tube will be a better option.

Video Demonstration of Laser Cutting Cordura® Vest

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting Non-Metal Applications

Clothing & Home Textiles

Clean and smooth edge with thermal treatment

Filtration Industry

The secret of exquisite pattern cutting

The selection of appropriate filter media decides the quality and economy of an entire filtration process, including solid-liquid separation and air filtration. Laser has been considered as the best technology for cutting filter media (Filter Cloth, Filter Foam, Fleece, Filter Bag, Filter Mesh, and other filtration applications)

Composite Materials

High Power Laser Cutting

Laser cutting can deliver high precision and constant quality results with fine laser beam. Inherent thermal processing guarantees sealed and smooth edges without fray and breakage on composite materials.

Outdoor Upholstery & Gear

Seamless laser cutting laminated fabric

The performance requirements are much higher for outdoor fabric. Sun protection, breathability, waterproof, wear resistance, all these functions usually require multiple layers of materials. Our industrial laser cutter is the most suitable tool for cutting such fabrics.

Common materials and applications

of Flatbed Laser Cutter 160L

Commercial laser cutter, industrial fabric cutting machine for sale

Add yourself to the list!

Product detail pictures:

Related Product Guide:

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for China Wholesale Camera Laser Cutter Manufacturers Suppliers - Flatbed Laser Cutter 160L – MimoWork Laser , The product will supply to all over the world, such as: Gabon , UK , Cologne , Our company's main items are widely used all over the world; 80% of our products and solutions exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.