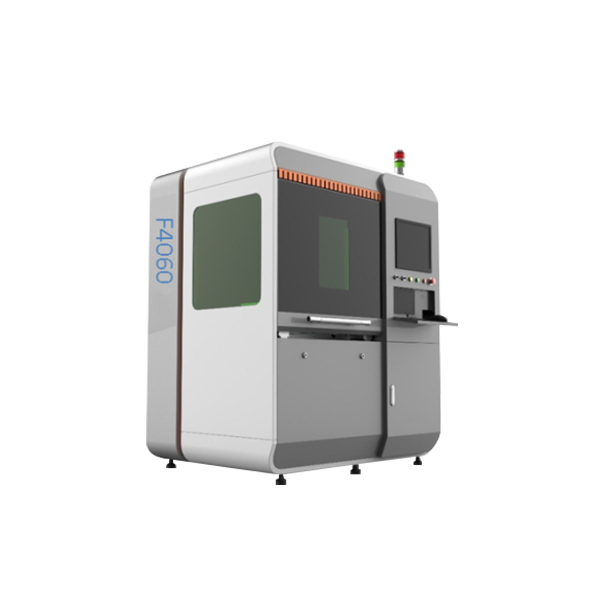

China Wholesale Co2 Laser Marking Machine Factories Pricelist - Flatbed Laser Cutter 250L – MimoWork Laser

China Wholesale Co2 Laser Marking Machine Factories Pricelist - Flatbed Laser Cutter 250L – MimoWork Laser Detail:

Advantages of Commercial Laser Cutter

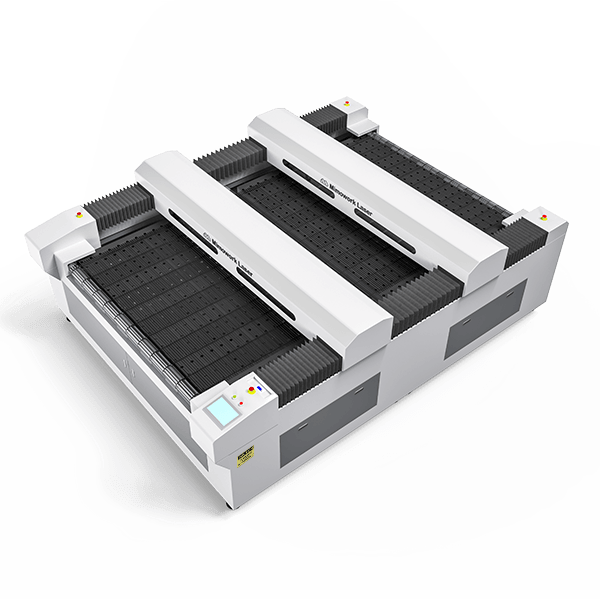

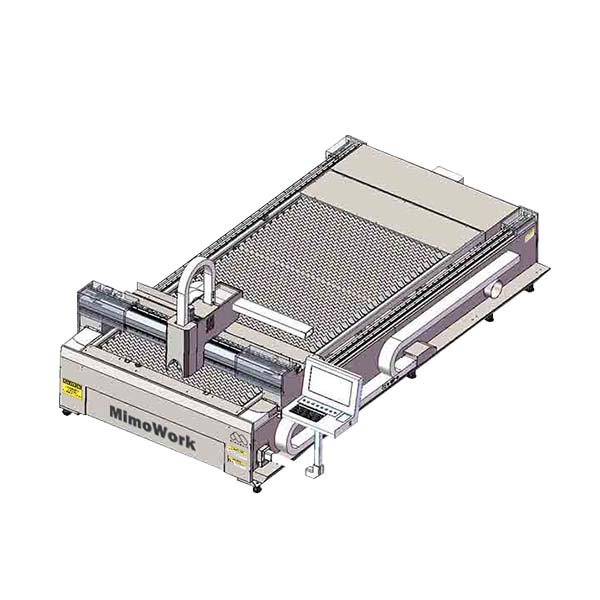

Ultimate Large Fabric Cutter

◉ Wide applications in industries such as outdoor equipment, technical textile, home textile

◉ Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Evolutionary visual recognition technology and powerful software provide higher quality and reliability for your business.

◉ Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional)

◉ Advanced mechanical structure allows laser options and customized working table

Technical Data

| Working Area (W * L) | 2500mm * 3000mm (98.4’’ *118’’) |

| Max Material Width | 98.4’’ |

| Software | Offline Software |

| Laser Power | 150W/300W/500W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Rack and Pinion Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

(Upgrade for your industrial fabric laser cutting machine, textile laser cutter)

Ideal for Technical Textile Laser Cutting

Auto Feeder

Auto Feeder is a feeding unit that runs synchronously with the laser cutting machine. The feeder will convey the roll materials to the cutting table after you put the rolls on the feeder. Feeding speed can be set according to your cutting speed. A sensor is equipped to ensure perfect material positioning and minimize errors. The feeder is able to attach different shaft diameters of rolls. The pneumatic roller can adapt textiles with various tension and thickness. This unit helps you to realize a completely automatic cutting process.

![]()

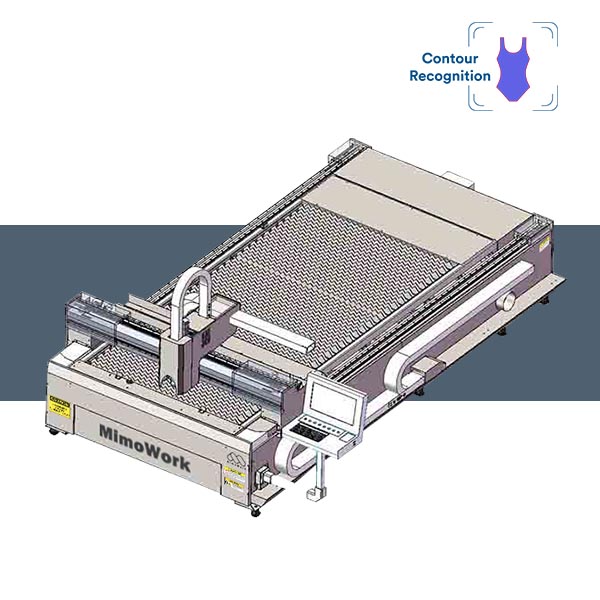

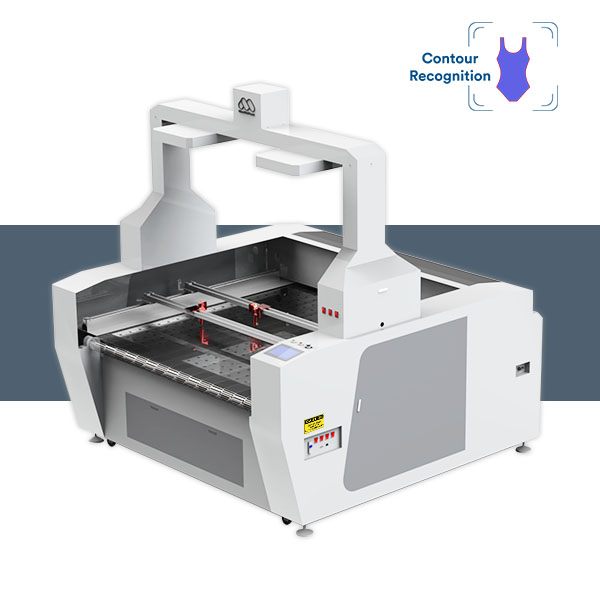

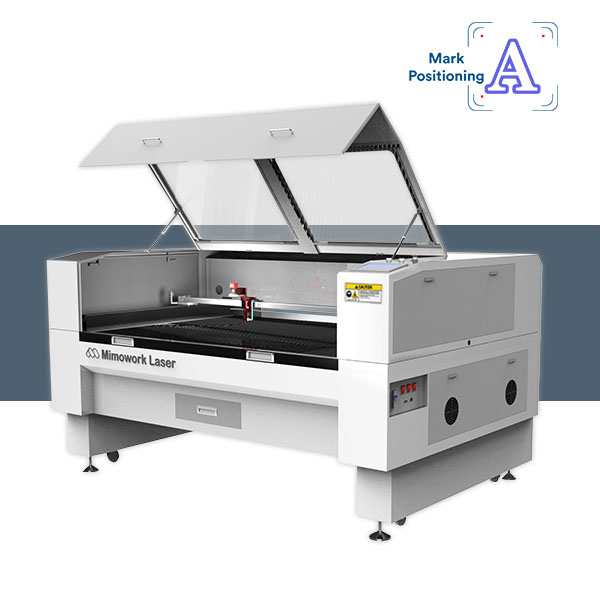

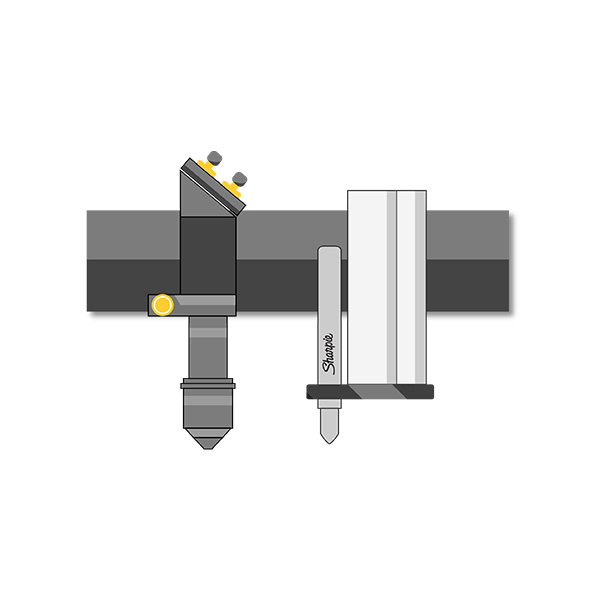

Vision System

When you are trying to cut out the contours, no matter printing contour or embroidery contour, you may need the Vision System to read the contour or special data for positioning and cutting. Varied options have been designed in our software packages such as contour scanning and marks scanning, serving diverse applications and requirements.

Ink-Jet Printing

Ink-Jet Printing is widely used for marking and coding products and packages. A high-pressure pump directs liquid ink from a reservoir through a gun-body and a microscopic nozzle, creating a continuous stream of ink droplets via the Plateau-Rayleigh instability. The ink-jet printing technology is a non-contact process and has a wider application in terms of different types of materials. Moreover, inks are also options, like volatile ink or non-volatile ink, MimoWork loves to help to choose according to your needs.

Video Glance | How to Laser Cut Fabric Duct

<a href="https://www.mimowork.com/video-gallery/" title="Source from: Video Gallery” target=”_blank”>

Source from: Video Gallery

<a href="https://www.mimowork.com/laser-cutting-fabric-duct-and-laser-perforating/" title="Click here to learn more [ laser cutting fabric duct ]” target=”_blank”>

Click here to learn more [ laser cutting fabric duct ]

Fields of Application

Laser Cutting for Your Industry

Composite Material

Engraving, marking, and cutting can be realized in single process

✔ High precision in cutting, marking, and perforating with fine laser beam

✔ Fewer material waste, no tool wear, better control of production costs

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

✔ Ensures a safe working environment during operation

Clothing & Home Textiles

Clean and smooth edge with thermal treatment

✔ Bringing about more economical and environment-friendly manufacturing process

✔ Customized working tables meet requirements for varieties of materials formats

✔ Quick response to market from samples to large-lot production

Outdoor Equipment

Your popular and wise manufacturing direction

✔ Smooth and lint-free edge through heat treatment

✔ High precision in cutting, marking, and perforating with fine laser beam

✔ Greatly saving cost in materials waste

Automotive & Aviation

The secret of exquisite pattern cutting

✔ Realize unattended cutting process, reduce manual workload

✔ High-quality value-added laser treatments like engraving, perforating, marking, etc Mimowork adaptable laser ability, suitable to cut diverse materials

✔ Customized tables meet requirements for varieties of materials formats

Common materials and applications

of Flatbed Laser Cutter 250L

Materials: Fabric, Leather, Nylon, Kevlar, Cordura, Coated Fabric, Polyester, EVA, Foam, Industrial Materials, Synthetic Fabric, and other Non-metal Materials

Applications: Functional Garment, Carpet, Automotive interior, Car Seat, Airbags, Filters, Air Dispersion Ducts, Home Textile (Mattress, Curtains, Sofas, Armchairs, Textile Wallpaper), Outdoor (Parachutes, Tents, Sports Equipment)

Material overview

Application overview

Learn more industrial fabric laser cutter price

Let’s know your requirements!

Product detail pictures:

Related Product Guide:

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for China Wholesale Co2 Laser Marking Machine Factories Pricelist - Flatbed Laser Cutter 250L – MimoWork Laser , The product will supply to all over the world, such as: Vietnam , Danish , Georgia , Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!