China Wholesale Co2 Laser Marking Machine Factories Pricelist - Galvo Laser Engraver & Marker 40 – MimoWork Laser

China Wholesale Co2 Laser Marking Machine Factories Pricelist - Galvo Laser Engraver & Marker 40 – MimoWork Laser Detail:

Advantages from Galvo Laser Engraver

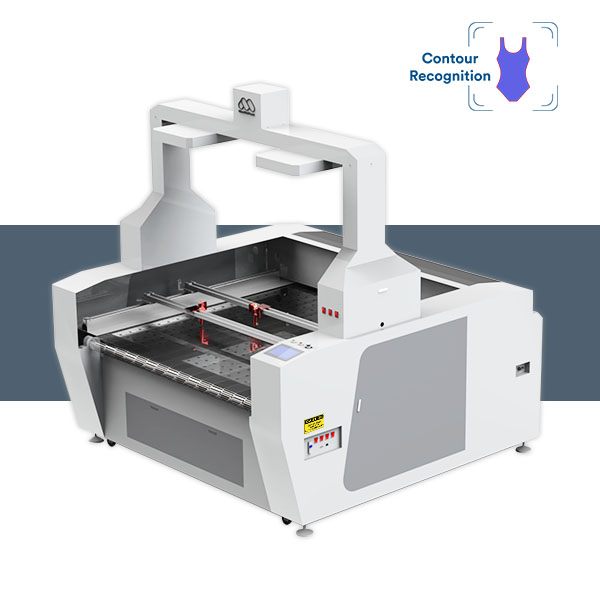

Best Entry-level GALVO Laser Machine

◉ Ultra-speed & high efficiency

Small deflection, but large action area. Flying laser marking from 3D dynamic focus declination quickly shoot the laser beam to the material, eliminating flatbed gantry moving time. Fast production timely responses the market requirements whether for customization or mass batch.

◉ Rich effect from versatile galvo laser

Besides laser engraving and marking, galvo laser can achieve cutting materials, cooperating with galvo laser engraving, to build coherent production assembly line. A multi-layered crafts from kiss-cutting is easy to realize on the paper, heat transfer film and foil.

◉ Fine details with high quality

Benefiting from deft laser path and applicable laser power, fine laser beam draw the artworks on the surface with high precision. Different diameters and heights of lens impact the ultimate effect.

◉ Safe & advanced laser structure

Enclosed laser structure provides a safe functioning space for work pieces and operator. Also, upgrade laser options are available to expand more production varieties.

(Superior Specifications for your fabric laser engraving machine, leather laser engraving machine, paper laser cutter)

Technical Data

| Working Area (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Beam Delivery | 3D Galvanometer |

| Laser Power | 180W/250W/500W |

| Laser Source | CO2 RF Metal Laser Tube |

| Mechanical System | Servo Driven, Belt Driven |

| Working Table | Honey Comb Working Table |

| Max Cutting Speed | 1~1000mm/s |

| Max Marking Speed | 1~10,000mm/s |

Highlight of GALVO Laser Engraver & Marker 40

GALVO Head

GALVO laser uses high-speed, motor-driven mirrors to steer the laser beam through the lens. Aiming at the material in the laser marking and laser engraving field, the beam impacts the material at a greater or lesser inclination angle. The marking field size is defined by the deflection angle and the focal length of the optics. As there is no mechanical movement during galvo laser functioning (with the exception of the mirrors), the laser beam can be guided over the workpiece at an extremely high speed. High efficiency and at the same time, high precision, make GALVO Laser Engraver & Marker 40 an ideal marking machine when it comes to short cycle times or high-quality markings.

For other GALVO views, diverse GALVO lenses are available. The biggest GALVO laser lens for this model is up to 800mm.

▶ Faster Speed

Improve your production efficiency

Rotary Device

Rotary Plate

X-Y Moving Table

Fields of Application

Glavo CO2 Laser for Your Industry

Kiss Cutting

(A laser tech that is widely used in laser cutting film, laser cutting foil, laser engraving leather patches)

✔ Fine incision and clean surface without materials damage due to contact-less processing

✔ Minimal defective rate with digital control system

✔ Consistent processing and high repeating ensure high efficiency and quality

Common materials and applications

of GALVO Laser Engraver & Marker 40

Materials: Film, Foil, Paper, Fleece, Denim, Leather, Acrylic(PMMA), Plastic, Wood,and other Non-metal Materials

Applications: Footwear, Invitation Card, Perforated Cloth, Car Seat Perforation, Garments Accessories, Bags, Labels, Packing, Puzzles, Sportswear, Jeans, Carpets, Curtains, Technical Textiles, Air Dispersion Ducts

View more materials

View more applications

Learn more about what is a galvo, galvo laser engraving denim

Add yourself to the list!

Product detail pictures:

Related Product Guide:

Just about every member from our large efficiency income crew values customers' wants and enterprise communication for China Wholesale Co2 Laser Marking Machine Factories Pricelist - Galvo Laser Engraver & Marker 40 – MimoWork Laser , The product will supply to all over the world, such as: Uruguay , Amman, Benin , We are eager to cooperate with foreign companies which care much on the real quality, stable supply, strong capability and good service. We can offer the most competitive price with high quality,because we are much MORE PROFESSIONAL. You are welcomed to visit our company at any time.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!