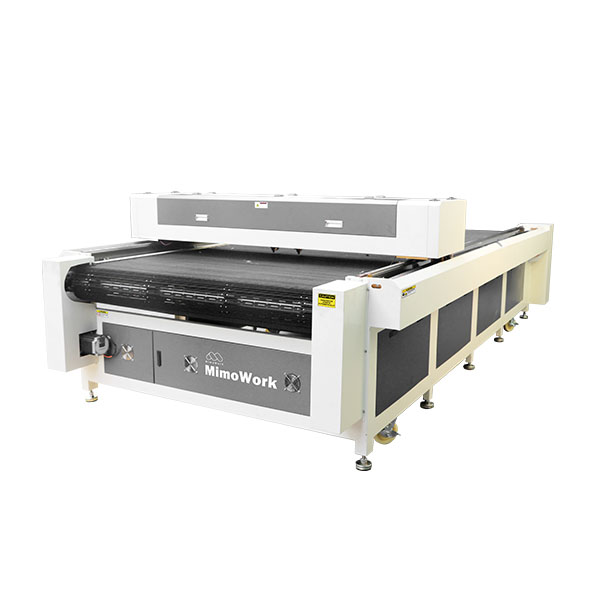

China Wholesale Fabric Cutter Laser Factories Quotes - Flatbed Laser Cutter 130L – MimoWork Laser

China Wholesale Fabric Cutter Laser Factories Quotes - Flatbed Laser Cutter 130L – MimoWork Laser Detail:

Advantages of Flatbed Laser Cutter

A Giant Leap in Productivity

Technical Data

| Working Area (W * L) | 1300mm * 2500mm (51” * 98.4”) |

| Software | Offline Software |

| Laser Power | 150W/300W |

| Laser Source | CO2 Glass Laser Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Knife Strip Working Table |

| Max Speed | 1~300mm/s |

| Acceleration Speed | 1000~3000mm/s2 |

R&D for Processing Acrylic And Wood

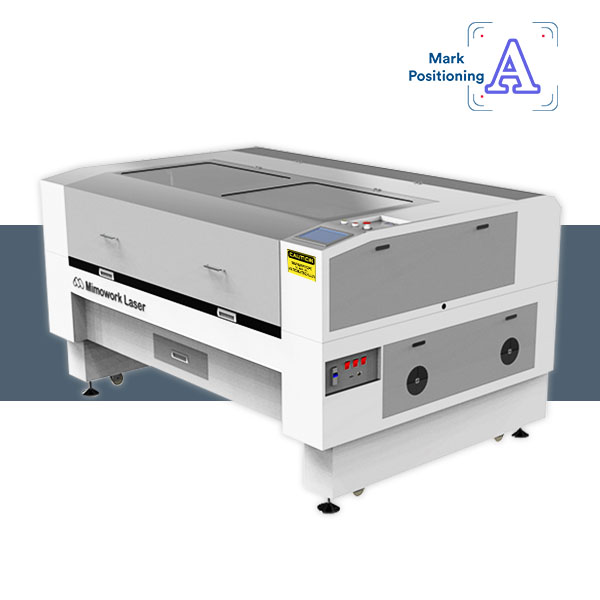

Belt Drive

A belt is a looped strip of flexible material used to mechanically link two or more rotating shafts. A belt drive offers smooth transmission of power between shafts at a considerable distance. Belt drives are used as the source of motion to transfer to efficiently transmit power or to track relative movement. In the motion of belt drive, power transmission results make one side of the pulley more tightened compared to the other side. In horizontal drives, the tightened side is always kept on the lower side of two pulleys because the sag of the upper side slightly increases the angle of the folding of the belt on the two pulleys. Belt drives are simple and economical.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

Video Demonstration of Laser Cutting Christmas Ornaments

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Advertising & Gifts

A clear and smooth edge without chipping

Digital Printing

Clean and smooth edge with thermal treatment

Common materials and applications

of Flatbed Laser Cutter 130L

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for China Wholesale Fabric Cutter Laser Factories Quotes - Flatbed Laser Cutter 130L – MimoWork Laser , The product will supply to all over the world, such as: Georgia , venezuela , Curacao , We are proud to supply our products to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.