China Wholesale Fiber Laser Cutters Manufacturers Suppliers - 100W Laser Cutter – MimoWork Laser

China Wholesale Fiber Laser Cutters Manufacturers Suppliers - 100W Laser Cutter – MimoWork Laser Detail:

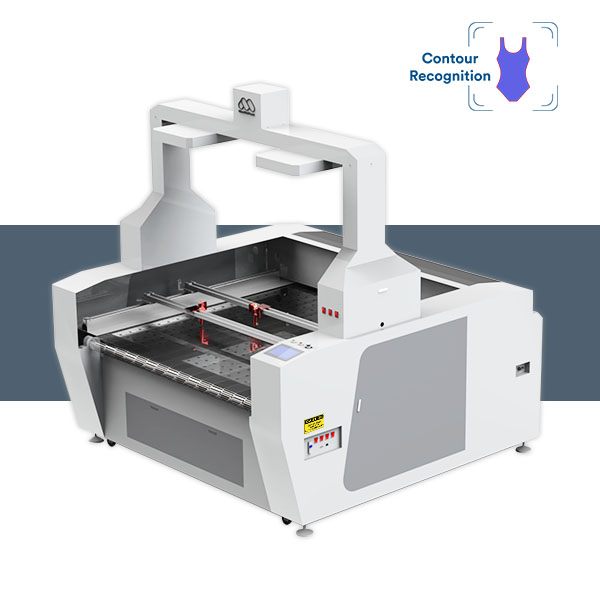

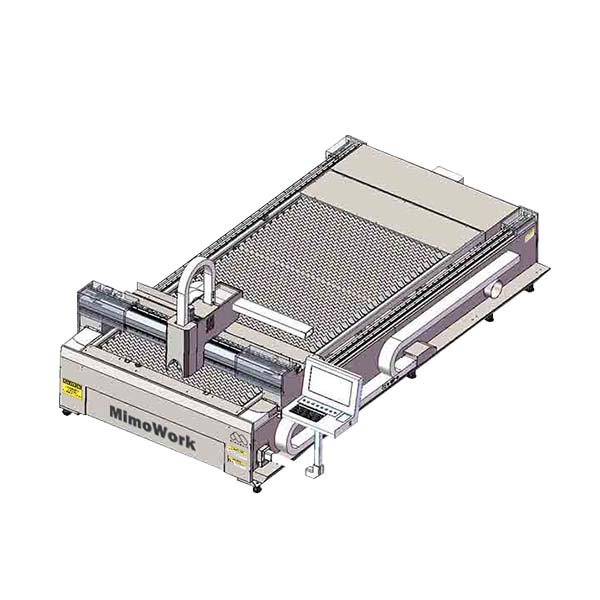

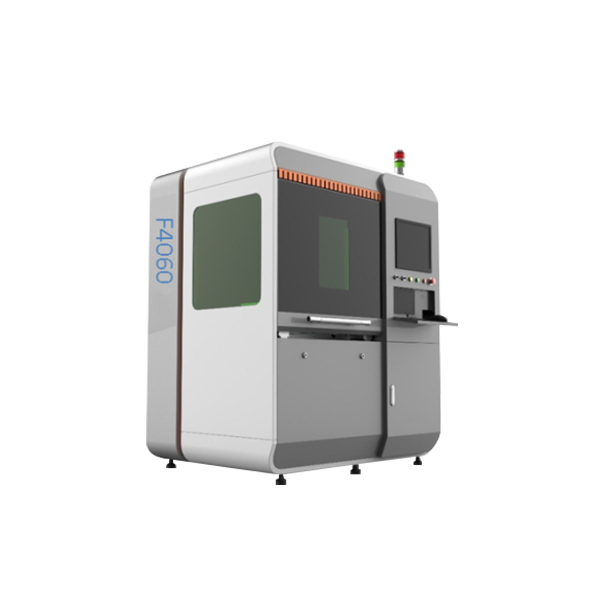

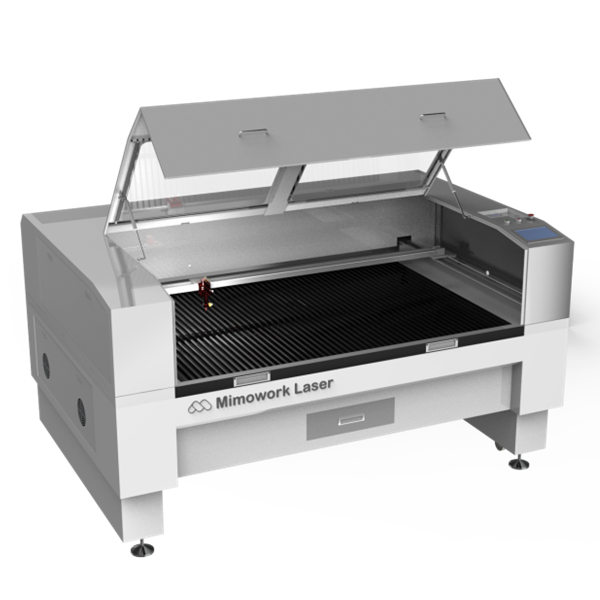

100W Laser Cutter – Solid Performance with Customization Options

Technical Data

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* More sizes of laser working table are customizable

* Higher Power Laser Tube are customizable

▶ FYI: The 100W Laser Cutter is suitable to cut and engrave on solid materials such as acrylic and wood. Honey comb working table and knife strip cutting table can carry the materials and help to reach best the cutting effect without dust and fume that can be sucked into and purified.

<a href="https://www.mimowork.com/working-table/" title=">> Discover laser cutting tables” target=”_blank”>

>> Discover laser cutting tables

<a href="https://www.mimowork.com/fume-extractor/" title=">> Discover laser fume extractor” target=”_blank”>

>> Discover laser fume extractor

100W CO2 Laser Cutter

Multifunction in One Machine

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

Auto Focus

It is mainly used for metal cutting. You may need to set a certain focus distance in the software when the cutting material is not flat or with different thickness. Then the laser head will automatically go up and down, keeping the same height & focus distance to match with what you set inside the software to achieve a consistently high cutting quality.

Ball & Screw

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional lead screws, ball screws tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls. The ball screw ensures high speed and high precision laser cutting.

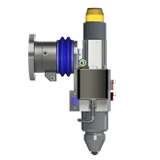

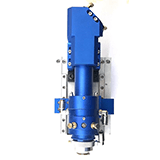

Mixed Laser Head

A mixed laser head, also known as a metal non-metallic laser cutting head, is a very important part of the metal & non-metal combined laser cutting machine. With this professional laser head, you can cut both metal and non-metal materials. There is a Z-Axis transmission part of the laser head that moves up and down to track the focus position. Its double drawer structure enables you to put two different focus lenses to cut the materials of different thicknesses without adjustment of focus distance or beam alignment. It increases cutting flexibility and makes the operation very easy. You can use different assist gas for different cutting jobs.

Looking for the latest upgrades for your 100W Laser Cutter?

Video of Laser Cutting Basswood Board

Turning Basswood into 3D Eiffel Tower Model

This 100W Laser Cutter can cut out complex, detailed shapes with clean and burn-free results. The keyword here is precision, accompanied by great cutting speed. When cutting wood boards as we showed in the video, you can’t go wrong with a laser cutter like this.

Field of Applications

Puzzles & Gifts

Unique advantages of laser cutting

✔ Clean and smooth edges with thermal sealing when processing

✔ No limitation on shape, size, and pattern realizes flexible customization

✔ Customized laser tables meet requirements for varieties of materials formats

Want to learn more about Laser Cutting Wood?

Decorations & Ornaments

Tips and Tricks to achieve Prefection

1. Higher purity acrylic sheet can achieve better cutting effect.

2. The edges of your pattern should not be too narrow.

3. Select the laser cutter with the right power for flame-polished edges.

4. The blowing should be as slight as possible to avoid heat diffusion which could also lead to burning edge.

Want to learn more about Laser Cutting Acrylic?

Common materials and applications

of 100W CO2 Laser Cutter

Materials: Acrylic, Wood, Paper, Plastic, Glass, MDF, Plywood, Laminates, Leather, and other Non-metal Materials

Applications: Signs(signage), Crafts, Jewelry, Key chains, Arts, Awards, Trophies, Gifts, etc.

View more materials

View more applications

Suitable Cutting Speed For 100W Laser Cutter

For your Reference

✔ Different Power output leads to Different Cutting Speed

✔ Choose the suitable and correct parameters for the best possible result

✔ Feel free to experiment, every project requires unique solution

Want to know what Cutting Speed suits your project?

Dozens of clients are Choosing US for the Latest Laser Solution

Add yourself to the list!

Product detail pictures:

Related Product Guide:

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers' demands for China Wholesale Fiber Laser Cutters Manufacturers Suppliers - 100W Laser Cutter – MimoWork Laser , The product will supply to all over the world, such as: Finland , Singapore , Portland , Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!