China Wholesale Fiber Optic Laser Cutter Factories Quotes - Sublimation Polyester Laser Cutter (180L) – MimoWork Laser

China Wholesale Fiber Optic Laser Cutter Factories Quotes - Sublimation Polyester Laser Cutter (180L) – MimoWork Laser Detail:

Laser Cutting Polyester With the Latest Advancements

Technical Data

| Working Area (W *L) | 1800mm * 1300mm (70.87’’ * 51.18’’) |

| Max Material Width | 1800mm / 70.87’’ |

| Laser Power | 100W/ 130W/ 300W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Dual-Laser-Heads option is available for laser cutting sublimation polyester

A Giant Leap For Polyester Laser Cutting

Best Choice for Cutting Large-Format Sublimation Polyester

▶ MimoWork’s Sublimation Polyester Laser Cutter (180L) with a generous working table size of 1800 mm*1300 mm is your ticket to effortless and precise cutting of sublimation fabrics!

▶ Perfectly suited for a range of industries, including digital printing products like advertising banners, clothing, and home textiles, this innovative technology allows for fast and accurate cutting of dye sublimation textiles.

▶ No need to worry about the challenge of cutting stretchy fabrics. Our Advanced Visual Recognition Technology and powerful software recognizes distortions or stretches in the fabric, ensuring the printed pieces are cut to the correct size and shape.

▶ But wait, there’s more! Our Automatic Feeding System and the conveying work platform work together to achieve an automatic roll-to-roll processing process, saving labor and boosting efficiency. And with laser cutting, the edges are sealed directly during the cut, so no additional processing is required.

D&R for Flexible Sublimation Polyester Laser Cutting

Large Working Table

With a larger and longer working table, it is suitable for a variety of industry applications. Whether you want to produce printed banners, flags, or ski-wear, a cycling jersey will be your right-hand man. With the auto-feeding system, it can help your cut out from a printed roll perfectly. And our working table width can be customized and perfectly fit with major printers and heat presses, such as Monti’s Calender for printing.

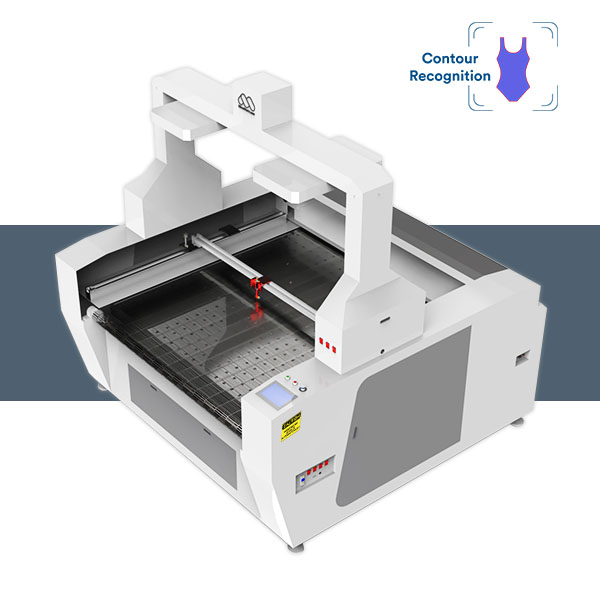

Cannon HD camera

Equipped Cannon HD camera on the top of the machine, this ensures that the Contour Recognition System can accurately identify the graphics that need to be cut. The system does not need to use original patterns or files. After automatic feeding, this is a fully automatic process without manual intervention. In addition, the camera will take pictures after the fabric is fed into the cutting area, and then adjust the cutting contour to eliminate deviation, deformation and rotation, and finally achieve a high-precision cutting effect.

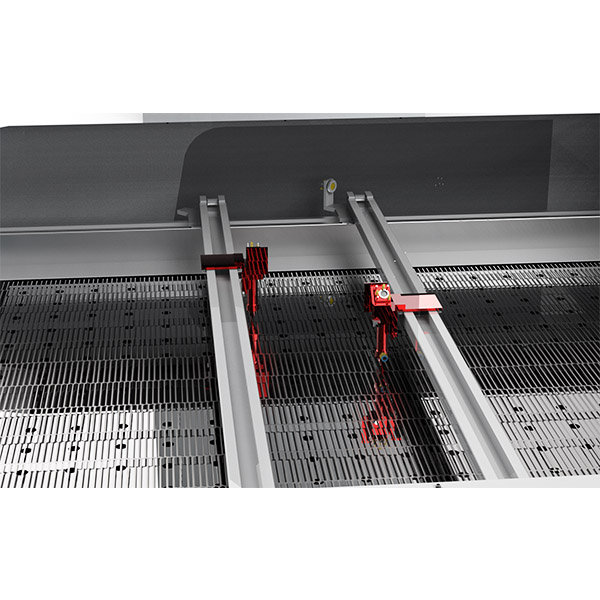

Conveyor Working Table

An increase in productivity thanks to auto-loading and unloading during the cutting process. The conveyor system is made out of stainless steel mesh, suitable for lightweight and stretchy fabrics, such as polyester fabrics and spandex, that’s commonly used in dye-sublimation fabrics. And through the specially set down exhaust system under the Conveyor Working Table, the fabric is fixed on the processing table tamely. Combined with the contact-less laser cutting, no distortion will appear despite the direction that the laser head is cutting.

Auto Feeder

Auto Feeder is a feeding unit that runs synchronously with the laser cutting machine. The feeder will convey the roll materials to the cutting table after you put the rolls on the feeder. Feeding speed can be set according to your cutting speed. A sensor is equipped to ensure perfect material positioning and minimize errors. The feeder is able to attach different shaft diameters of rolls. The pneumatic roller can adapt textiles with various tension and thickness. This unit helps you to realize a completely automatic cutting process. Using it with a conveyor table is a great choice.

Video Display

<a href="https://www.mimowork.com/laser-cutting-polyester/" title="<

<< Laser Cutting Sublimation Pillowcase

Looking to streamline your sublimation printing process? Look no further than our sublimation laser cutter with camera recognition technology! With automatic pattern positioning and contour cutting, this innovative machine eliminates the need for manual intervention and post-trimming. Say goodbye to lengthy workflows and hello to improved production efficiency!

Whether for sublimation printed fabric or solid fabric, contactless laser cutting ensures textiles are fixed and not damaged.

>” target=”_self”>

How to Laser Cut Sublimation Flag >>

To meet the demands of accurate cutting along the contour in printed advertising field, MimoWork recommends the laser cutter for sublimation textiles like teardrop flag, banner, signage, etc.

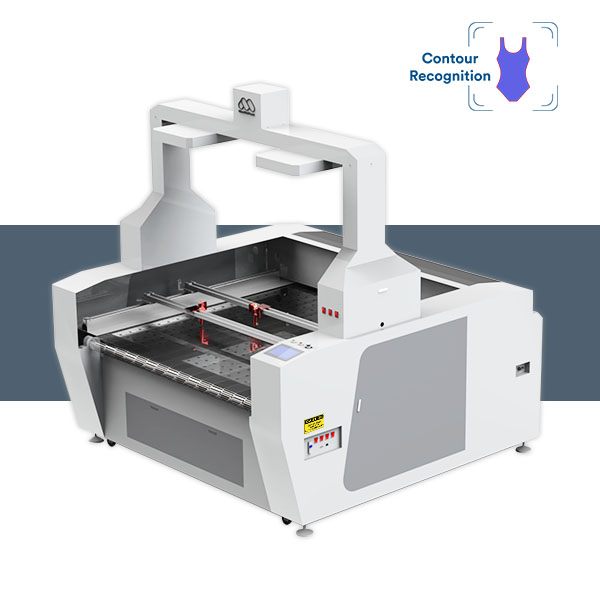

Besides for the smart camera recognition system, the contour laser cutter features large format working table and dual laser heads, facilitating flexible and quick production as different market needs.

<a href="https://www.mimowork.com/sublimation-fabrics-laser-cutter/" title=" >> Discover Sublimation Textile Laser Cutting” target=”_blank”>

>> Discover Sublimation Textile Laser Cutting

<a href="https://www.mimowork.com/laser-cutting-sublimation-fabrics-sportswear/" title="<

<< Laser Cutting Sublimation Sportswear

CO2 laser cutting is a highly versatile and efficient method for precision cutting of polyester sportswear fabrics. Using a focused CO2 laser beam, this technology offers clean and precise cuts, ensuring intricate designs and seamless edges without fraying or distortion. With the help of the camera, the sublimation polyester laser cutter can cut customized sportswear garments, including jerseys, shorts, and activewear. This innovative cutting process not only enhances design flexibility but also reduces production time and material waste, making it a preferred choice for high-quality and customized sportswear manufacturing.

<a href="https://www.mimowork.com/laser-cutting-sublimation-fabrics-sportswear/" title=" >> Explore Laser Cutting Sublimation Sportswear” target=”_blank”>

>> Explore Laser Cutting Sublimation Sportswear

Find more videos about our laser cutters at our Video Gallery

Having Doubts About Sublimation Polyester Laser Cutting?

Fields of Application

The Bright Future of Laser Cutting Polyester

<a href="https://www.mimowork.com/laser-cutting-sublimation-fabrics-sportswear/" title="Dye-Sublimation Sportswear

& Polyester Laser Cutter” target=”_blank”>

Dye-Sublimation Sportswear

& Polyester Laser Cutter

Cutting From The Printed Roll Directly

✔ The contour recognition system allows the exact cut along the printed contours

✔ Fusion of cutting edges – no need for trimming

✔ Ideal for processing stretchy and easily distorted materials

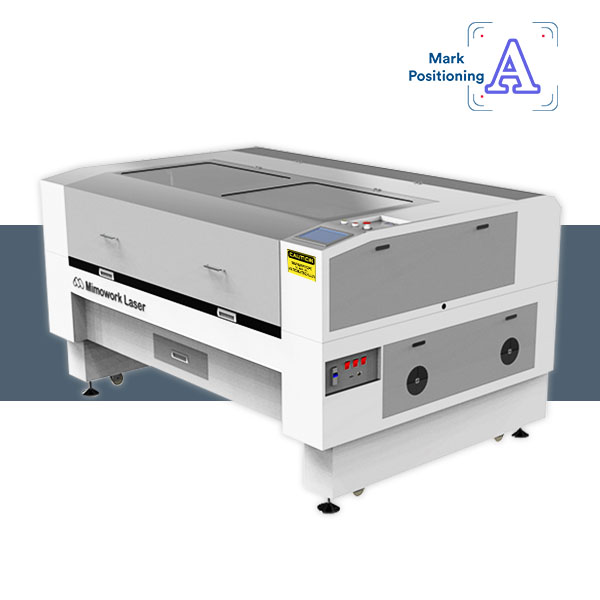

Banners & Displays

Looking to broaden the breadth of your business?

Our versatile and flexible laser treatments can help! With mark point positioning technology, our laser cutter can cut along pressure contours with pinpoint accuracy. But that’s not all – our laser also offers value-added abilities like engraving, perforating, and marking, making it the perfect fit for entrepreneurs and small businesses looking to up their game.

Other Materials & Applications

of Sublimation Polyester Laser Cutter 180L

Materials: Spandex, Lycra, Silk, Nylon, Cotton, and other sublimation fabrics

Applications: Rally Pennants, Flag, Signage, Billboard, Swimwear, Leggings, Sportswear, Uniforms

FAQ of Laser Cutting Sublimation Polyester

# Can you laser cut polyester?

Polyester fabric can indeed be laser cut, and the choice of the ideal laser type depends on several factors such as fabric thickness, desired cutting speed, and level of detail needed. Among the options, CO2 lasers stand out as a versatile and widely used choice for cutting polyester. Their precision and ability to cut through various materials make them suitable for intricate designs on polyester sportswear.

<a href="https://www.mimowork.com/laser-cutting-polyester/" title=">> Learn more about laser cutting polyester” target=”_blank”>

>> Learn more about laser cutting polyester

# What laser setting is needed to cut sublimation polyester?

For laser cutting sublimation fabrics like polyester, the laser speed and laser power are significant in the laser parameters setting. Usually we suggest using 100W or 150W to cut polyester fabric due to the material thickness and density. The cutting speed is usually set between 500 mm/s to 1000 mm/s for polyester fabric. Adjust the cutting speed based on the material thickness and desired cutting quality. Besides that, our laser machine is equipped with an air blower to assist in removing smoke and heat. If you are gonna purchasing sublimation polyester laser cutter, our laser expert will guide you in installation and machine debugging. No worry about that laser machine setting.

# Why laser is suitable to cut sublimation polyster?

The laser cutter with camera is the ideal choice to cut sublimation fabrics like polyester sportswear, signage, banner and others. Thanks to the high-precision laser cutting and accurate recognition for printed pattern, the sublimation laser cutter can quickly and accurately cut through the printed polyester fabrics without any distortion and error.

Related Laser Cutter

<a href="https://www.mimowork.com/contour-laser-cutting-machine/sublimation-polyester-laser-cutter-160l.html" title="Sublimation Polyester Laser Cutter

(160L)” target=”_blank”>

Sublimation Polyester Laser Cutter

(160L)

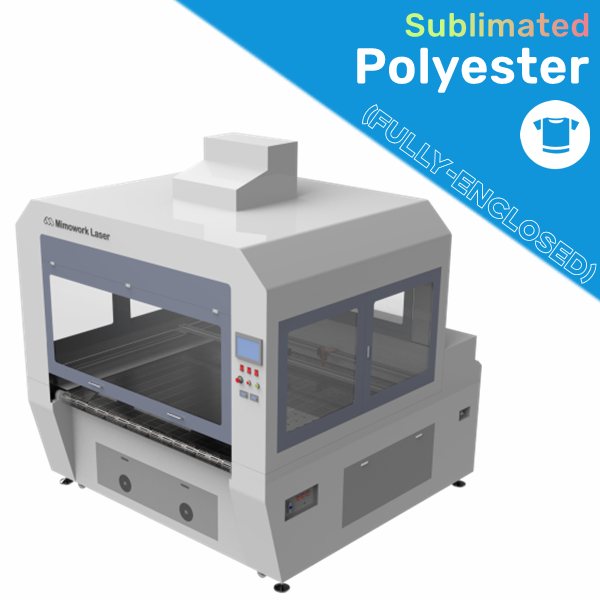

<a href="https://www.mimowork.com/contour-laser-cutting-machine/sublimation-polyester-laser-cutter-fully-enclosed.html" title="Sublimation Polyester Laser Cutter

(Fully-Enclosed)” target=”_blank”>

Sublimation Polyester Laser Cutter

(Fully-Enclosed)

We Don’t Settle for Mediocre Results, Our Aim is Higher

We Accept Perfections

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our improvement strategy for China Wholesale Fiber Optic Laser Cutter Factories Quotes - Sublimation Polyester Laser Cutter (180L) – MimoWork Laser , The product will supply to all over the world, such as: Singapore , Kyrgyzstan , Jamaica , We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.