China Wholesale Flatbed Co2 Laser Cutting Machine Factories Pricelist - MDF Laser Cutter – MimoWork Laser

China Wholesale Flatbed Co2 Laser Cutting Machine Factories Pricelist - MDF Laser Cutter – MimoWork Laser Detail:

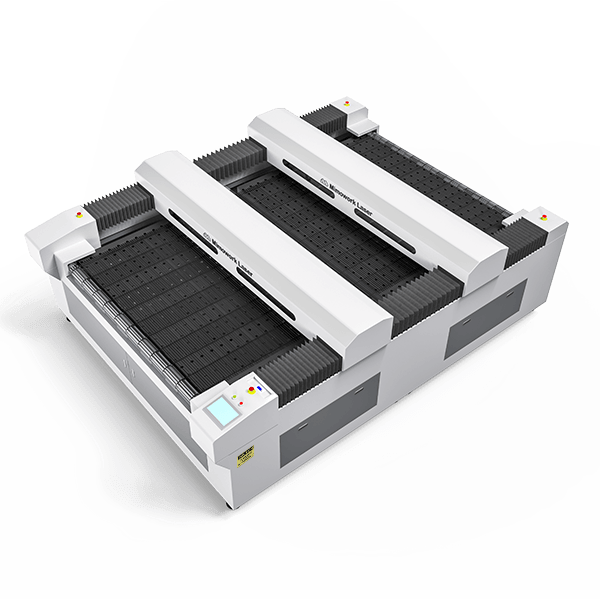

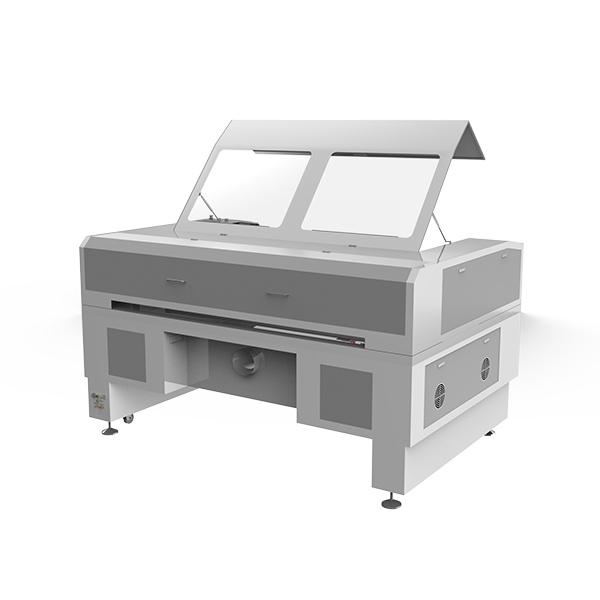

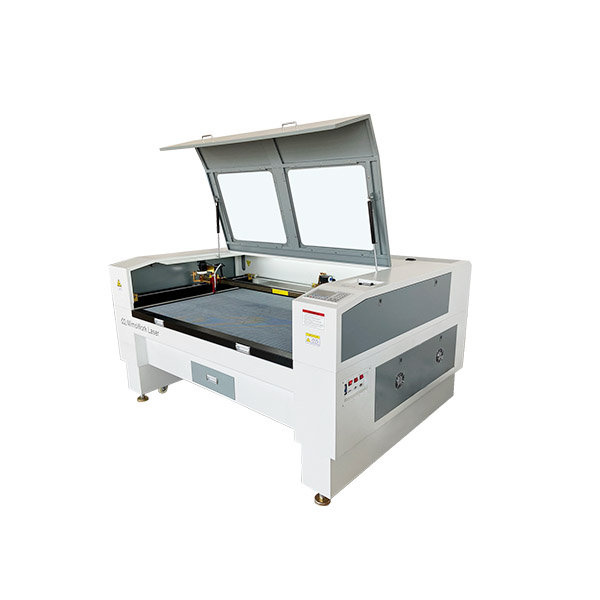

▶ MDF wood laser cutter and laser engraver

Technical Data

|

Working Area (W *L) |

1300mm * 900mm (51.2” * 35.4 ”) |

|

Software |

Offline Software |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

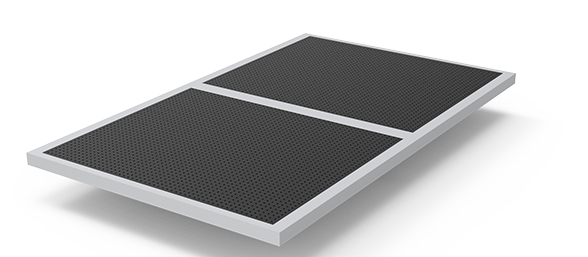

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

2050mm * 1650mm * 1270mm (80.7” * 64.9” * 50.0”) |

|

Weight |

620kg |

Multifunction in One Machine

Vacuum Table

With the aid of the vacuum table, the fume and waste gas can be timely dispelled and sucked into an exhaust fan for being further dealing. The strong suction not only fixes the MDF but protects the wood surface and back from scorching.

Two-way Penetration Design

Laser cutting and engraving on the large format MDF wood can be realized easily thanks to the two-way penetration design, which allows wood board placed through the whole width machine, even beyond the table area. Your production, whether cutting and engraving, will be flexible and efficient.

Stable and Safe Structure

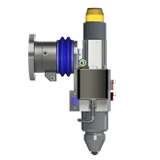

◾ Adjustable Air Assist

Air assist can blow the debris and chippings from the surface of wood, and protect the MDF from scorching during laser cutting and engraving. Compressed air from the air pump is delivered into the carved lines and incision through the nozzle, clearing the extra heat gathered on the depth. If you want to achieve burning and darkness vision, adjust the pressure and size of airflow for your desire. Any questions to consult us if you are confused about that.

◾ Exhaust Fan

The lingering gas can be absorbed into the exhaust fan to eliminate the smoke bothering the MDF and laser cutting. Downdraft ventilation system cooperated with fume filter can bring out the waste gas and clean the processing environment.

◾ Emergency Button

Happen to some sudden and unexpected condition, the emergency button will be your safety guarantee by stopping the machine at once.

◾ Safe Circuit

Smooth operation makes a requirement for the function-well circuit, whose safety is the premise of safety production.

◾ CE Certification

Owning the legal right of marketing and distributing, MimoWork Laser Machine has been proud of the solid and reliable quality.

▶ MimoWork Laser options contributes to your mdf laser cut projects

Upgrade options for you to choose

>> More Laser Options

Auto Focus

For some materials with uneven surfaces, you need the auto-focus device that controls the laser head to go up and down to realize a consistently high cutting quality. Different focus distances will affect the cutting depth, so the auto-focus is convenient to process these materials (like wood and metal) with varied thicknesses.

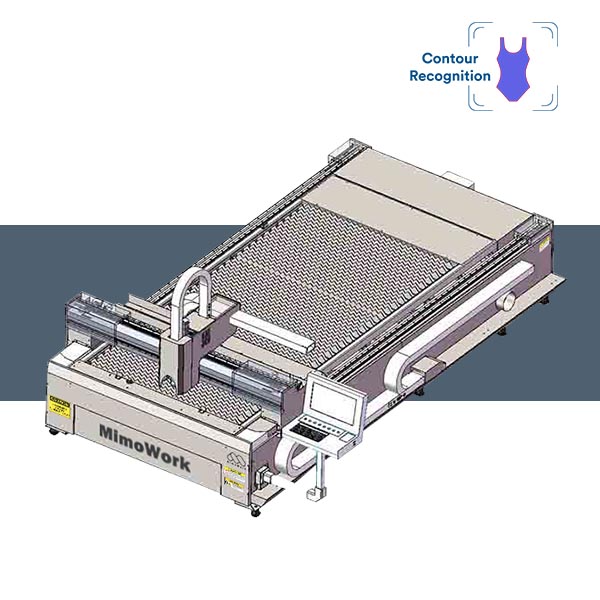

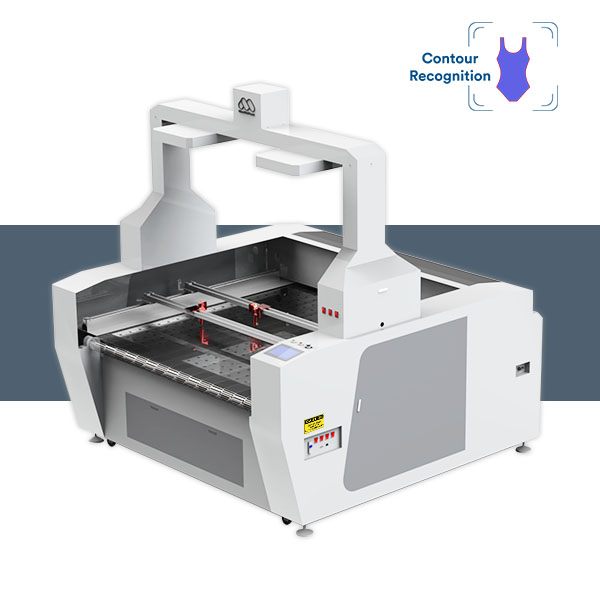

CCD Camera

The CCD Camera can recognize and position the pattern on the printed MDF, assisting the laser cutter to realize accurate cutting with high quality. Any customized graphic design printed can be flexibly processed along the outline with the optical recognition system. You can use it for your customized production or hobby of hand-making.

Mixed Laser Head

A mixed laser head, also known as a metal non-metallic laser cutting head, is a very important part of the metal & non-metal combined laser cutting machine. With this professional laser head, you can cut both metal and non-metal materials. There is a Z-Axis transmission part of the laser head that moves up and down to track the focus position. Its double drawer structure enables you to put two different focus lenses to cut the materials of different thicknesses without adjustment of focus distance or beam alignment. It increases cutting flexibility and makes the operation very easy. You can use different assist gas for different cutting jobs.

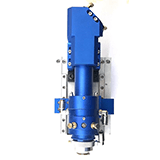

Ball & Screw

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional lead screws, ball screws tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls. The ball screw ensures high speed and high precision laser cutting.

Motors

>> Learn more about motors

(mdf laser cut letters, mdf laser cut names, mdf laser cut terrain)

MDF samples of laser cutting

Pictures Browse

>> learn about MDF laser

Other Wood Materials

— laser cutting and engraving wood

Bamboo, Balsa Wood, Beech, Cherry, Chipboard, Cork, Hardwood, Laminated Wood, Multiplex, Natural Wood, Oak, Plywood, Solid Wood, Timber, Teak, Veneers, Walnut…

Related Links:

# Video Gallery for wood cutting

# Wood Laser Cutting & Engraving

# Mimo-Pedia for laser knowledge

Any questions about laser cutting & laser engraving MDF

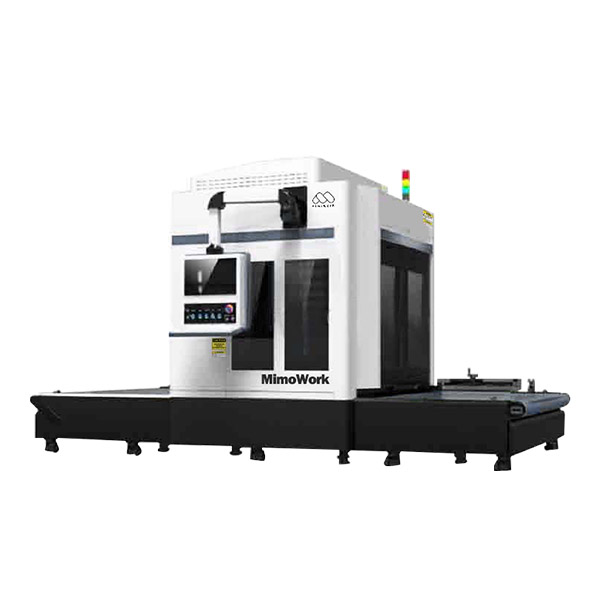

MDF Laser Cut Machine

for wood and acrylic laser cutting

Flatbed Laser Cutter 130L

• Suitable for large format solid materials

• Cutting multi-thickness with optional power of laser tube

for wood and acrylic laser engraving

Desktop Laser Engraver 70

• Light and compact design

• Easy to operate for beginners

MDF wood laser cutter machine price, how thick MDF can laser cut

Inquire us to learn more!

Product detail pictures:

Related Product Guide:

To create far more benefit for customers is our company philosophy; customer growing is our working chase for China Wholesale Flatbed Co2 Laser Cutting Machine Factories Pricelist - MDF Laser Cutter – MimoWork Laser , The product will supply to all over the world, such as: Milan , Orlando , Serbia , With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.