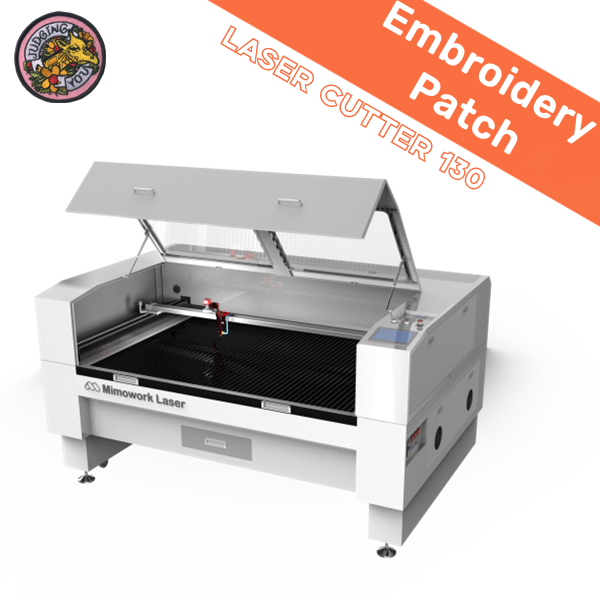

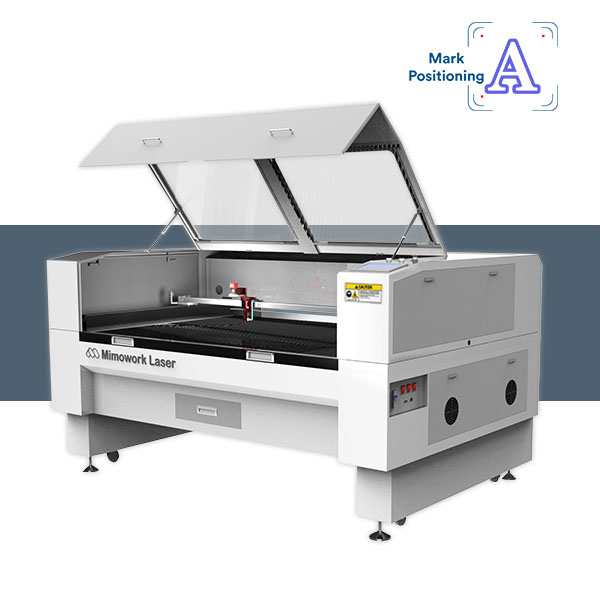

China Wholesale Flatbed Laser Cutter Machine Manual Factories Pricelist - Embroidery Patch Laser Cutting Machine 130 – MimoWork Laser

China Wholesale Flatbed Laser Cutter Machine Manual Factories Pricelist - Embroidery Patch Laser Cutting Machine 130 – MimoWork Laser Detail:

Embroidery Patch Laser Cutting Made Easy & Creative

Technical Data

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Advantages of Embroidery Patch Laser Cutting Machine 130

Upgraded Precision & Increased Production

◼ Specific for cutting Large Batches of Customized Complex designs of Embroidery Patches

◼ Optional to Upgrade your Laser Power to 300W for Cutting Thick Material

◼ Precise CCD Camera Recognition System ensures tolerance within 0.05mm

◼ Optional servo motor for extremely high speed cutting

◼ Flexible pattern cutting along the contour as your different design files

Multifunction in One Machine

Knife Stripe Working Table

Besides laser honeycomb bed, MimoWork provides the knife stripe working table to suit solid materials cutting. The gap between the stripes makes it not easy to accumulate waste and much easier to clean after processing.

<a href="https://www.mimowork.com/working-table/" title=">> Optional laser cutter tables” target=”_blank”>

>> Optional laser cutter tables

Optional Lifting Working Table

The working table can be moved up and down on Z-axis when cutting products with different thickness, which makes the processing more extensive.

Pass-through Design

The front and back pass-through design of Embroidery Patch Laser Cutting Machine 130 unfreezes the limitation of processing longer materials that exceeds the working table. No need to cut down the materials to adaptive the working table length in advance.

Video Demo – Embroidery Patch Laser Cutting

Find more videos about our laser cutters at our Video Gallery

Wanna Know More about Embroidery Patch Laser Cutting?

Highlights of Laser Cutting Embroidery Patches

Laser Cutting for You – Tailored & Customized

Laser Cutting Embroidery Patches

Clean and smooth edge with thermal treatment

Accurate and precise cutting of embroidery patches, clean and sharp edge.

Can cut a wide range of materials, ideal for producing different types of patches with various designs and sizes.

Production time of embroidery patches is significantly reduced, allowing for faster turnaround times and increased productivity.

Flexible cutting according to design files without the need for costly model and tool replacements, is the ideal solution for tailor-made patches.

The laser can handle intricate and detailed designs that may not be achievable with traditional cutting methods.

Laser cutting results in minimal material waste, making it a cost-effective and eco-friendly solution for producing embroidery patches.

CCD cameras on laser cutting machines offer visual guidance on the cutting path, ensuring accurate contour cutting for any shape, pattern, or size.

Embroidery Patch – Why Laser Cutting?

Showoff your Personality with Detailed Cuts

Embroidery patches are a great way to add a touch of personality and style to any outfit or accessory. However, the traditional methods of cutting and designing these patches can be time-consuming and tedious. That’s where laser cutting comes in! Laser cutting embroidery patches has revolutionized the patch-making process, providing a quicker, more precise, and efficient way to create patches with intricate designs and shapes.

With a laser cutting machine specifically designed for embroidery patches, you can achieve a level of precision and detail that was previously impossible.

Other Materials & Applications

of Embroidery Patch Laser Cutting Machine 130

Materials: Acrylic, Plastic, Wood, Glass, Laminates, Leather

Applications: Signs, Signage, Abs, Display, Key chain, Arts, Crafts, Awards, Trophies, Gifts, etc.

Other Laser Cutter – You Might be Interested in

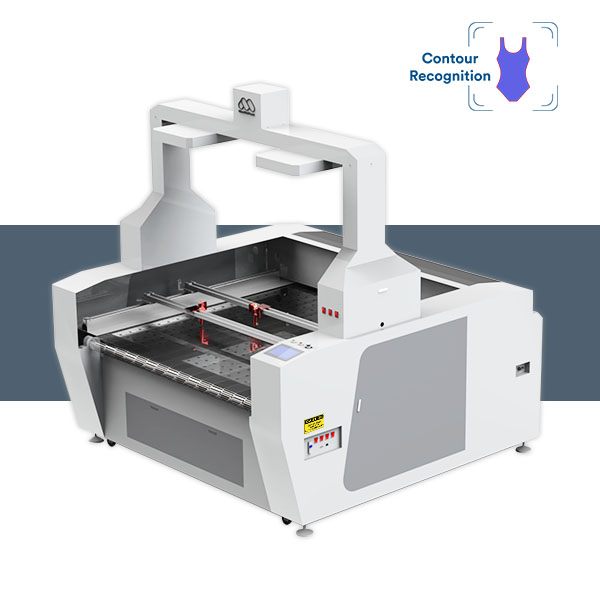

Vision Laser Cutting Machines

<a href="https://www.mimowork.com/contour-laser-cutting-machine/laser-cut-sportswear-machine-160l.html" title=" Laser Cut Sportswear Machine

(160L)” target=”_blank”>

Laser Cut Sportswear Machine

(160L)

Wanna Start your Embroidery Patch Laser Cutting Business?

MimoWork is here to Support you!

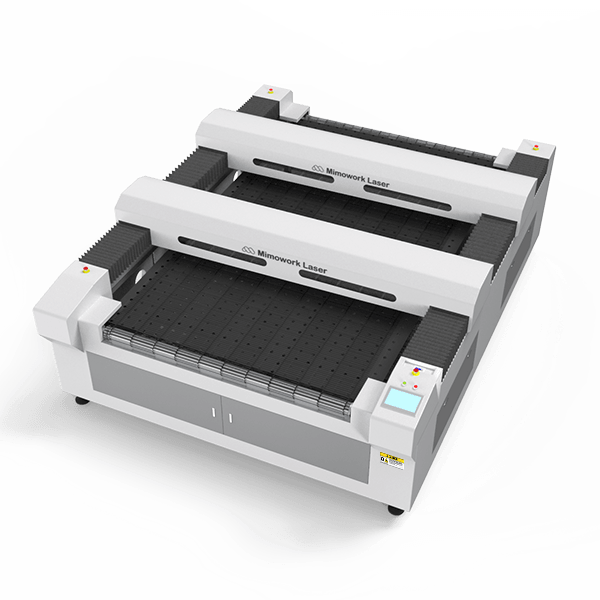

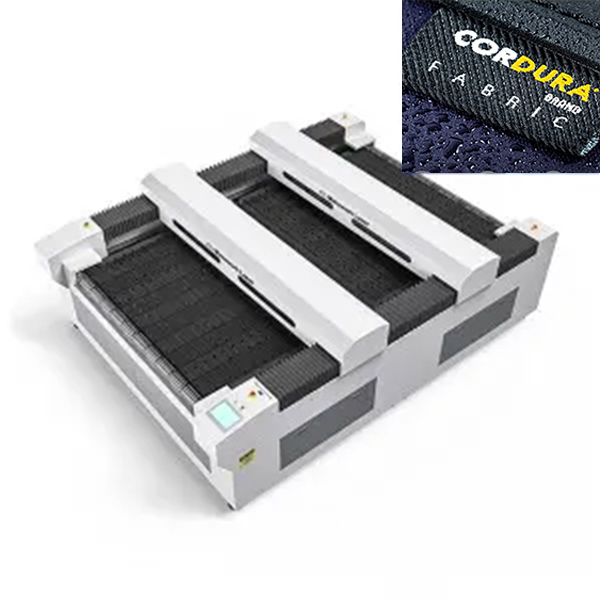

Product detail pictures:

Related Product Guide:

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for China Wholesale Flatbed Laser Cutter Machine Manual Factories Pricelist - Embroidery Patch Laser Cutting Machine 130 – MimoWork Laser , The product will supply to all over the world, such as: Netherlands , Oman , Sudan , Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.