China Wholesale Flatbed Laser Cutter Video Manufacturers Suppliers - CCD Laser Cutter – Automatic Pattern Recognition – MimoWork Laser

China Wholesale Flatbed Laser Cutter Video Manufacturers Suppliers - CCD Laser Cutter – Automatic Pattern Recognition – MimoWork Laser Detail:

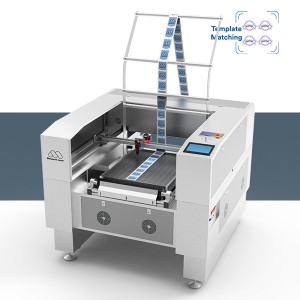

Ultra High Precision CCD Camera Laser Cutting Machine

Technical Data

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | CCD Camera Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Customized Working Area (W*L):

600mm * 400mm (23.6” * 15.7”)

900mm * 500mm (35.4” * 19.6”)

1600mm * 1,000mm (62.9’’ * 39.3’’)

The Highlights of CCD Laser Cutter

Optical Recognition System

◾ CCD Camera

The CCD Camera can recognize and position the pattern on the patch, label, printed acrylic, or some printed textiles, then instruct the laser head to achieve accurate cutting along the contour. Top-quality with flexible cutting for customized pattern and shape designs like logos, and letters. There are several recognition modes: take a photo for recognition, mark point positioning, and template matching. MimoWork will offer a guide on how to choose appropriate recognition modes to fit your production.

◾ Real-Time Monitoring

Together with the CCD Camera, the corresponding camera recognition system provides a monitor displayer to inspect the real-time production condition on a computer.

That is convenient for remote control and timely make an adjustment, smoothing production working flow as well as making sure safety.

Strong & Flexible Machine Structure

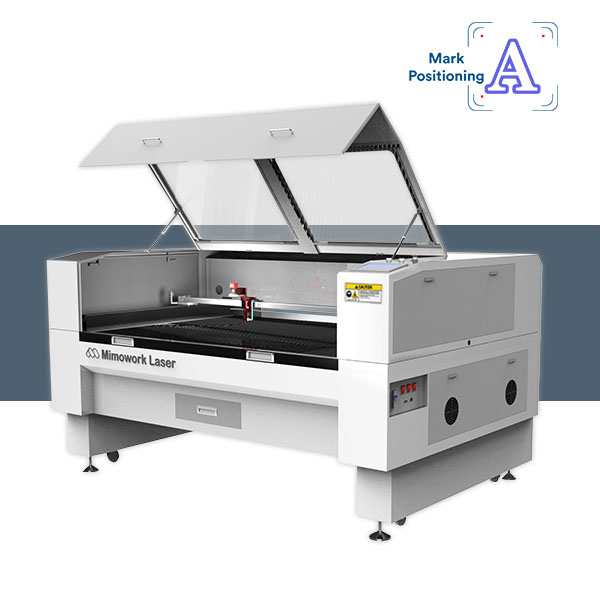

◾ Enclosed Design

The enclosed design provides a safe and clean work environment without fumes and odor leaks. You can look through the acrylic window to check the CCD laser cutting and monitor the real-time condition inside.

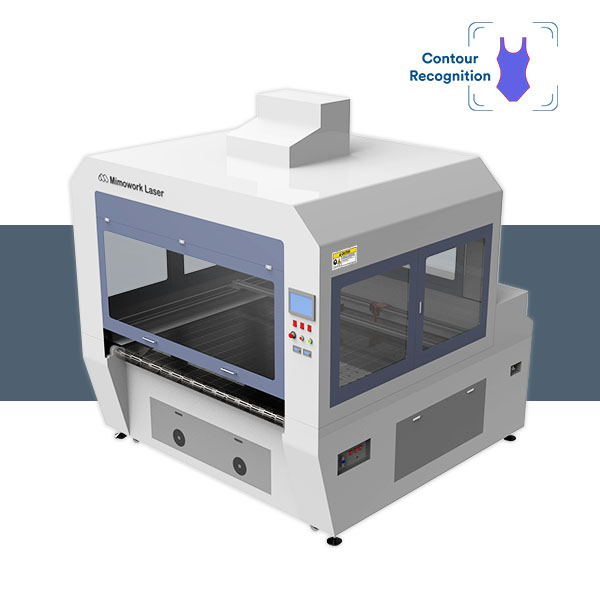

◾ Pass-Through Design

The pass-through design makes cutting ultra-long materials possible.

For example, if your acrylic sheet is longer than the working area, but your cutting pattern is within the working area, then you do not need to replace a larger laser machine, the CCD laser cutter with a pass-through structure can help you with your production.

◾ Air Blower

Air assistance is significant for you to ensure smooth production. We put the air assist next to the laser head, it can clear off the fumes and particles during laser cutting, to ensure the material and CCD camera and laser lens clean.

For another, the air assist can decrease the temperature of the processing area (that is called the heat-affected area), leading to a clean and flat cutting edge.

Our air pump can be adjusted to change the air pressure, which is suitable for different materials processing including acrylic, wood, patch, woven label, printed film, etc.

◾ Touch-Control Panel

This is the newest laser software and control panel. The touch-screen panel makes it easier to adjust the parameters. You can directly monitor amperage (mA) and water temperature right from the display screen.

Besides, the new control system further optimizes the cutting path, especially for the motion of dual heads and dual gantries. That improves the cutting efficiency.

You can adjust and save new parameters in terms of your materials to be processed, or use preset parameters built in the system. Convenient and friendly to operate.

Safety Device

◾ Emergency Button

An emergency stop, also known as a kill switch (E-stop), is a safety mechanism used to shut down a machine in an emergency when it cannot be shut down in the usual way. The emergency stop ensures the safety of operators during the production process.

◾ Signal Light

Signal light can indicate the working situation and functions exerting of laser machine, helps you to do the right judgment and operation.

Customize Laser Configurations for Your CCD Laser Cutter

Upgrade Your Production with Laser Options

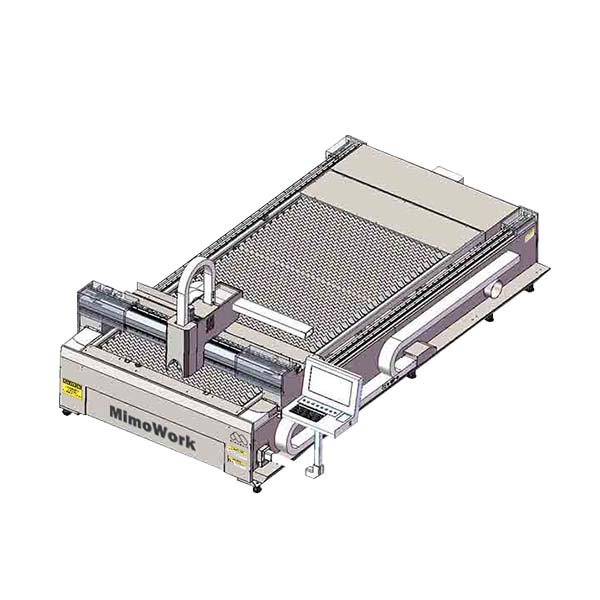

Shuttle Table

With the optional Shuttle Table, there will be two working tables that can work alternately. When one working table completes the cutting work, the other one will replace it. Collecting, placing material and cutting can be carried out at the same time to ensure production efficiency.

Fume Extractor

The fume extractor, together with the exhaust fan, can absorb the waste gas, pungent odor, and airborne residues. There are different types and formats to select according to actual patch production. On the one hand, the optional filtration system ensures a clean working environment, and on the other one is about environmental protection by purifying the waste.

Servo Motor

Servo motors ensure higher speed and higher precision of laser cutting and engraving. A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops.

Auto Focus Device

The auto-focus device is an advanced upgrade for your CCD camera laser cutting machine, designed to automatically adjust the distance between the laser head nozzle and the material being cut or engraved. This smart feature accurately finds the optimal focal length, ensuring precise and consistent laser performance across your projects. Without the need for manual calibration, the auto-focus device improves your work more precisely and efficiently.

RF Laser Tube

RF (Radio Frequency) laser tubes are high-performance, durable laser sources commonly used in industrial applications. Unlike traditional CO2 glass tubes, RF tubes are made of metal, which allows for better heat dissipation and longer lifespans, often exceeding 20,000 hours of use. They are air-cooled and offer superior precision, making them ideal for detailed engraving and fast pulsing tasks. While they come at a higher cost compared to glass tubes, their longevity, reliability, and enhanced engraving quality make RF laser tubes a preferred choice for professionals looking for top-tier performance.

How to Select Suitable Laser Options for Your CCD Laser Cutter?

What Can You Do with the CCD Laser Cutter?

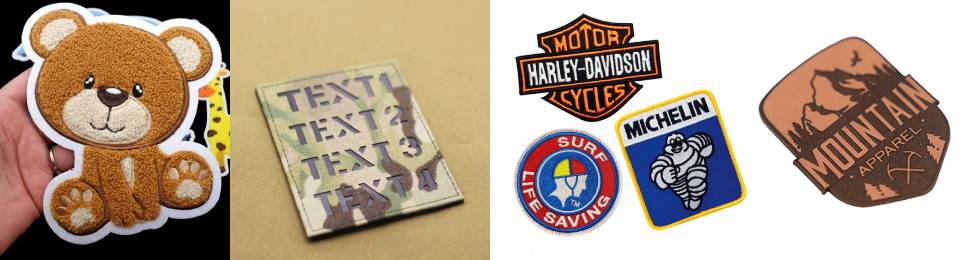

1. Laser Cutting Patches

.center-video {

display: flex;

justify-content: center;

}

Video Tutorial: CCD Camera Laser Cutting Embroidery Patch

Step1. Put the material on the honeycomb laser cutting bed.

Step2. CCD camera recognizes the feature area of the embroidery patch.

Step3. Template matching the patches, and simulate the cutting route.

Step4. Set the laser parameters, and start laser cutting.

More Laser Cut Patches Samples

• laser cut embroidery patches

• laser cut lace

• laser cut vinyl decals

• laser cut ir patches

• laser cut twill letters

• laser cut Cordura patches

• laser cut Velcro patches

• laser cut leather patches

• laser cut flag patches

2. Laser Cutting Woven Label

.center-video {

display: flex;

justify-content: center;

}

Video Demo: How to Laser Cut Roll Woven Label?

You can use the CCD camera laser cutting machine to cut woven label. The CCD camera is able to recognize the pattern and cut along the contour to produce a perfect and clean cutting effect.

For roll woven label, our CCD camera laser cutter can be equipped with a specially designed auto-feeder and conveyor table according to your label roll size.

The recognition and cutting process is automatic and fast, greatly increase the production efficiency.

More Laser Cut Woven Labels

<a href="https://www.mimowork.com/laser-cutting-woven-label/" title="▷ Learn more about laser cutting roll woven label” target=”_blank”>

▷ Learn more about laser cutting roll woven label

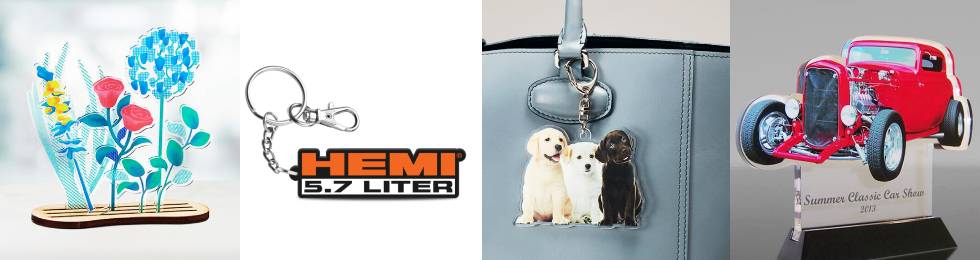

3. Laser Cutting Printed Acrylic & Wood

.center-video {

display: flex;

justify-content: center;

}

Video Display: CCD Camera Laser Cutting Printed Acrylic

The cut edges of laser cutting acrylic technology will display no smoke residue, implying that the white back will remain perfect. The applied ink was not harmed by the laser cutting. This indicates that the print quality was outstanding all the way to the cut edge.

The cut edge did not require polishing or post-processing because the laser-produced the requisite smooth cut edge in one pass. The conclusion is that cutting printed acrylic with a CCD laser cutter can produce the desired results.

More Samples of Laser Cut Printed Acrylic & Wood

<a href="https://www.mimowork.com/laser-cutting-printed-acrylic/" title="▷ Learn more about laser cutting printed acrylic” target=”_blank”>

▷ Learn more about laser cutting printed acrylic

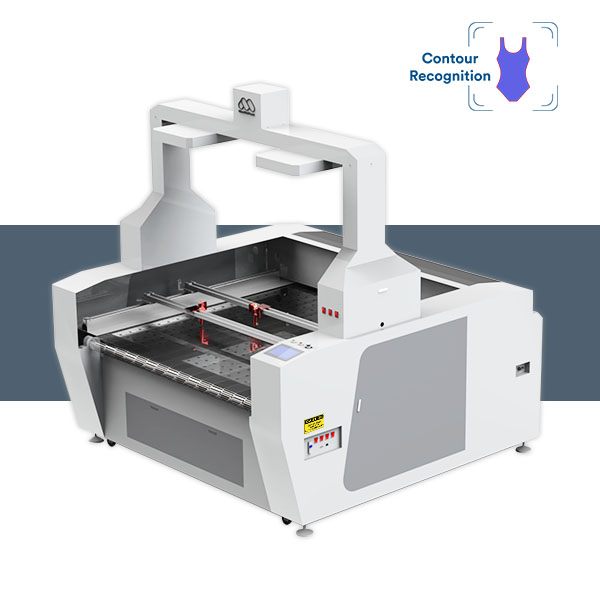

4. Laser Cutting Sublimation Textiles

.center-video {

display: flex;

justify-content: center;

}

Video Display: CCD Camera Laser Cutting Sublimation Pillowcase

The CCD Camera laser cutting machine not only cut small pieces like patches, acrylic decorations, but also cut large roll fabrics like sublimated pillowcase.

In this video, we used the contour laser cutter 160 with an auto-feeder and conveyor table. The working area of 1600mm * 1000mm can hold the pillowcase fabric and keep it flat and fixed on the table.

If you want to cut larger format of sublimation fabrics like teardrop flag, sportswear, leggings, we suggest you should choose the sublimation laser cutting machines that have various working areas:

5. Other Samples of CCD Camera Laser Cutting

.center-video {

display: flex;

justify-content: center;

}

• laser cut printed film

• laser cut apparel accessories

• laser cut stickers

• laser cut vinyl

• laser cut armband

• laser cut applique

• laser cut business card

What are You gonna Make with the CCD Laser Cutter?

We are here to help!

More CCD Laser Cutting Machine

Desktop Laser Cutter for Patch

• Laser Power: 65W

• Working Area: 600mm * 400mm

Roll Woven Label Laser Cutter

• Laser Power: 65W

• Working Area: 400mm * 500mm

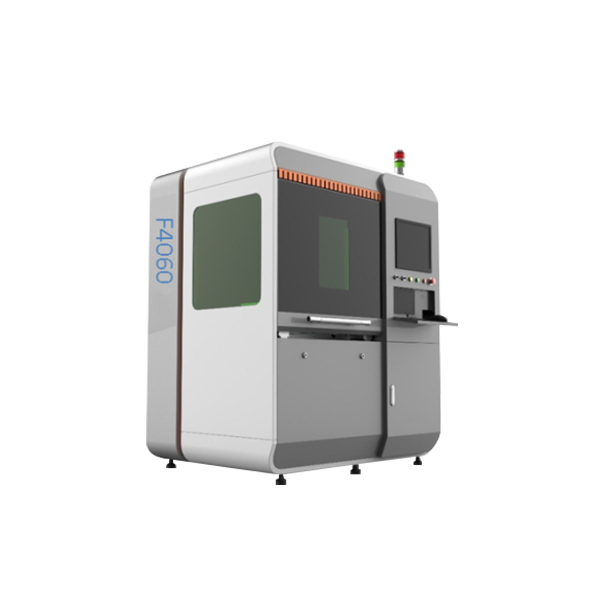

Printed Acrylic Laser Cutter

• Laser Power: 100W/150W/300W

• Working Area: 1300mm * 900mm

Related Articles

Complete Guide: How to Maintain & Care Your Laser Machine?

How to Select Laser Cutting Bed?

Laser Cutting Technique: Kiss Cutting

Improve Your Production with the CCD Camera Laser Cutter

Click Here to Learn More!

Product detail pictures:

Related Product Guide:

Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for China Wholesale Flatbed Laser Cutter Video Manufacturers Suppliers - CCD Laser Cutter – Automatic Pattern Recognition – MimoWork Laser , The product will supply to all over the world, such as: Madagascar , Ottawa , France , We warmly welcome your patronage and will serve our clients both at home and abroad with products of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!