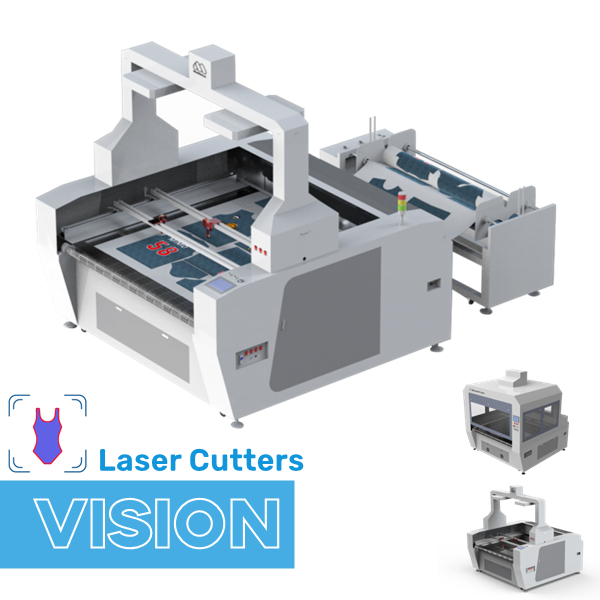

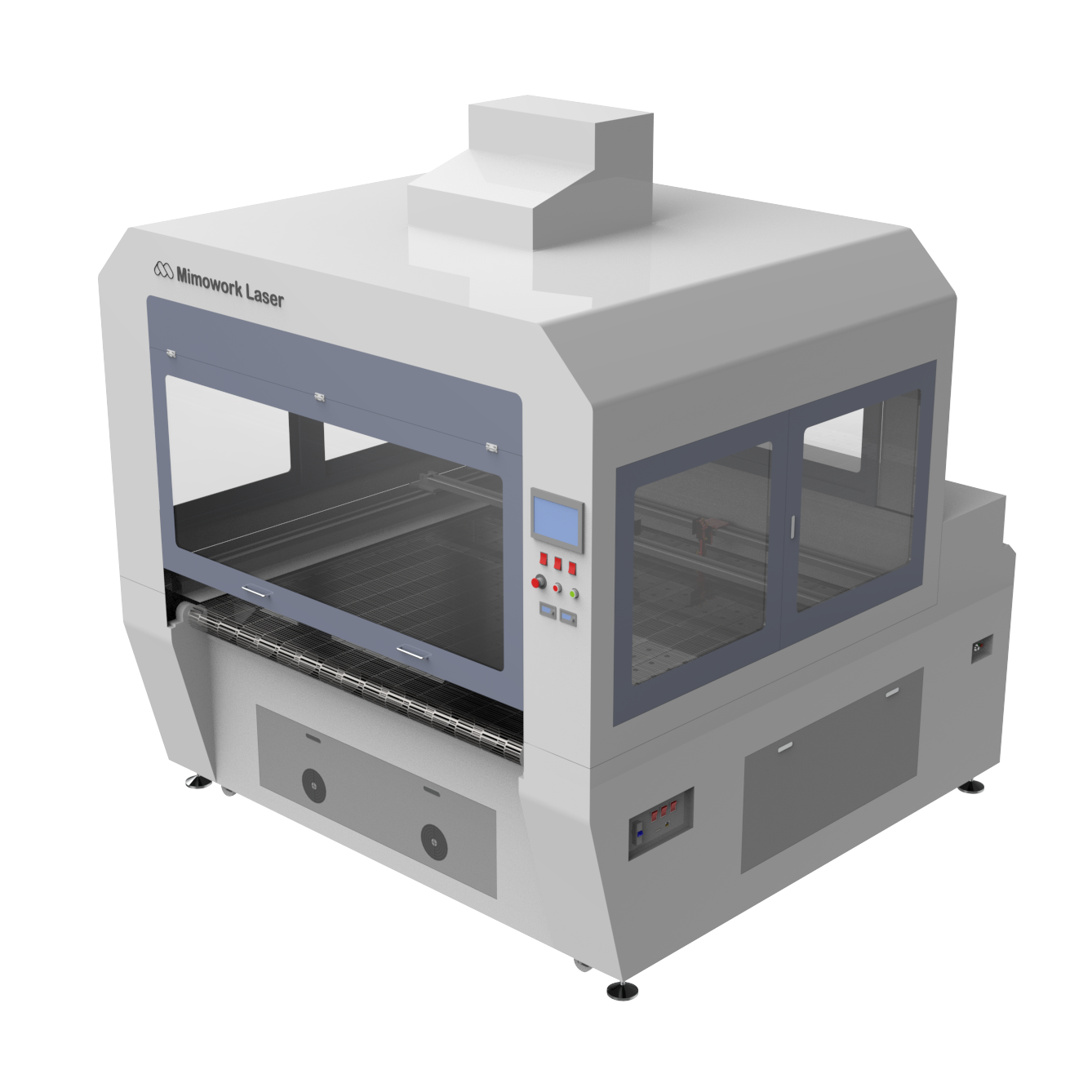

China Wholesale High Speed Vision Laser Cutting Machine Factories Quotes - Vision Laser Cutting Machine – MimoWork Laser

China Wholesale High Speed Vision Laser Cutting Machine Factories Quotes - Vision Laser Cutting Machine – MimoWork Laser Detail:

Technical Data

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

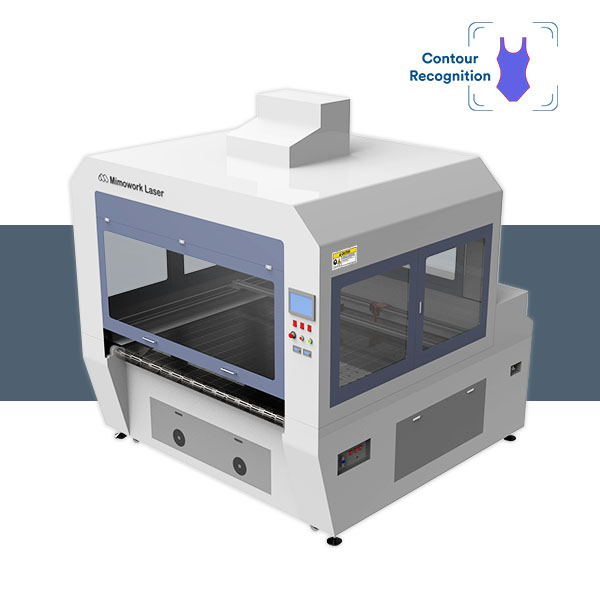

Advantages of Contour Laser Cutter for printed materials

Laser Cutting Made Easy

◼ Specific for cutting digital printed solid materials like printed acrylic, wood, plastic, etc

◼ High laser power option to 300W for cutting thick material

◼ Precise CCD Camera Recognition System ensures tolerance within 0.05mm

◼ Optional servo motor for extremely high speed cutting

◼ Flexible pattern cutting along the contour as your different design files

Multifunction in One Machine

Knife Stripe Working Table

Besides laser honeycomb bed, MimoWork provides the knife stripe working table to suit solid materials cutting. The gap between the stripes makes it not easy to accumulate waste and much easier to clean after processing.

<a href="https://www.mimowork.com/working-table/" title=">> Optional laser cutter tables” target=”_blank”>

>> Optional laser cutter tables

Optional Lifting Working Table

The working table can be moved up and down on Z-axis when cutting products with different thickness, which makes the processing more extensive.

Pass-through Design

The front and back pass-through design of Contour Laser Cutter 130 unfreezes the limitation of processing longer materials that exceeds the working table. No need to cut down the materials to adaptive the working table length in advance.

Video Demo of Laser Cutting Printed Acrylic

Find more videos about our laser cutters at our Video Gallery

For the video, any question about how the vision laser cutter works

Fields of Application

Laser Cutting for Your Industry

Digital Printing

Clean and smooth edge with thermal treatment

✔ Bringing about more economical and environment-friendly manufacturing process

✔ Customized working tables meet requirements for varieties of materials formats

✔ Quick response to market from samples to large-lot production

Advertising & Gifts

Unique advantages of laser cutting signs & decorations

✔ Clean and smooth edges with thermal melting when processing

✔ No limitation on shape, size, and pattern realizes flexible customization

✔ Customized tables meet requirements for varieties of materials formats

Common materials and applications

of Flatbed Laser Cutter 130

Materials: Acrylic, Plastic, Wood, Glass, Laminates, Leather

Applications: Signs, Signage, Abs, Display, Key chain, Arts, Crafts, Awards, Trophies, Gifts, etc.

Learn more about CCD Camera Laser Cutting Machine,

MimoWork is here to support you!

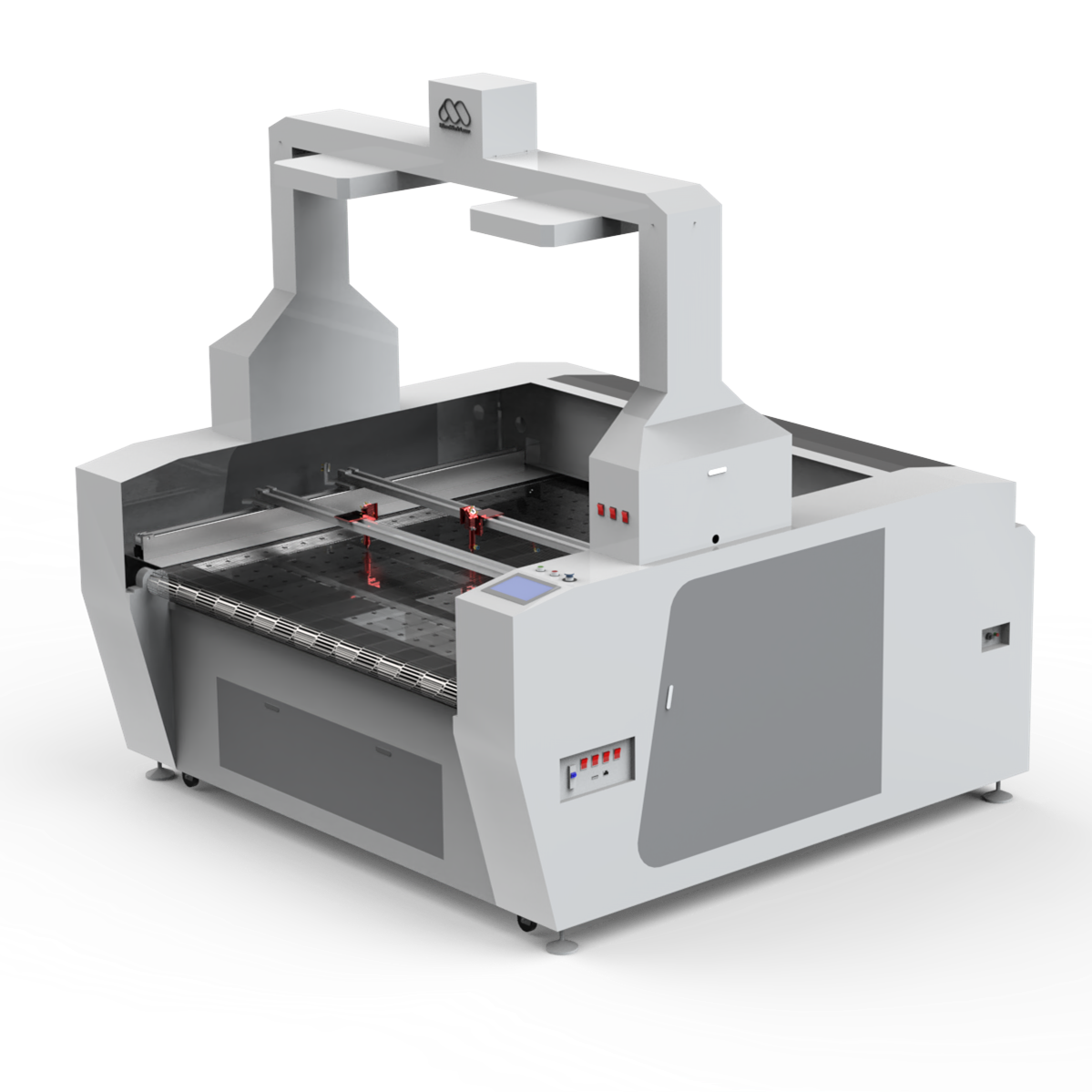

Product detail pictures:

Related Product Guide:

We've been commitment to offer the competitive rate ,outstanding merchandise good quality, too as fast delivery for China Wholesale High Speed Vision Laser Cutting Machine Factories Quotes - Vision Laser Cutting Machine – MimoWork Laser , The product will supply to all over the world, such as: Anguilla , America , Monaco , We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!