China Wholesale Large Format Dye Sub Laser Cutter Manufacturers Suppliers - Laser Cut Sportswear Machine (Fully-Enclosed) – MimoWork Laser

China Wholesale Large Format Dye Sub Laser Cutter Manufacturers Suppliers - Laser Cut Sportswear Machine (Fully-Enclosed) – MimoWork Laser Detail:

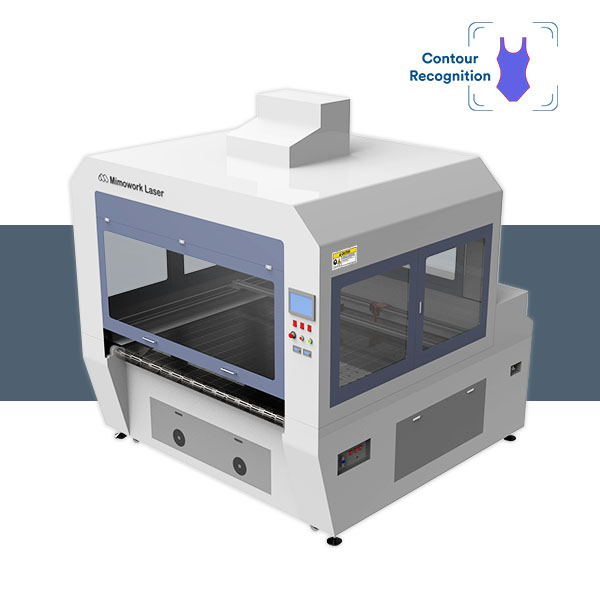

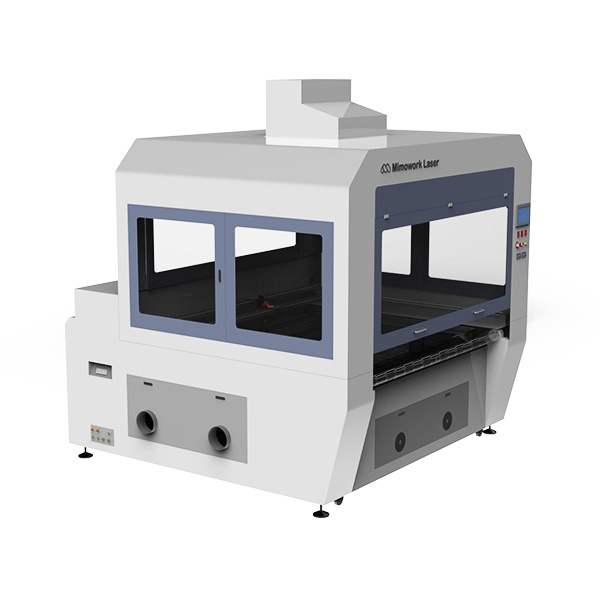

Fully Enclosed Sublimation Laser Cutter – Safer & Better

Technical Data

| Working Area (W *L) | 1800mm * 1300mm (70.87’’ * 51.18’’) |

| Max Material Width | 1800mm ( 70.87’’ ) |

| Laser Power | 100W/ 130W/ 150W/ 300W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

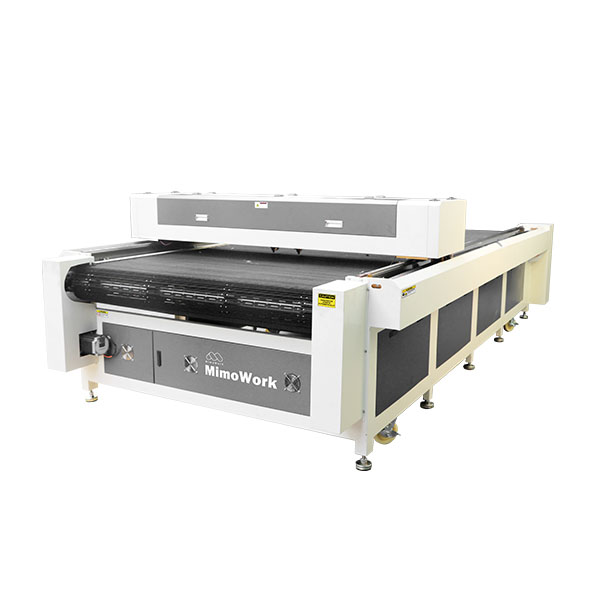

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Dual Laser Head option available

The Latest from Mimowork – Laser Cutting Sublimation Sportswear

MimoWork Laser Offers the Best & Safest

Looking for a cutting-edge solution to meet your business needs in digital printing, composite materials, clothing, and home textiles? Look no further than MimoWork laser cutting technology!

1. With flexible and fast capabilities, this innovative technology allows you to quickly respond to market needs and broaden the scope of your business.

2. The powerful software, backed by Advanced Visual Recognition technology, ensures high quality and reliability for your products.

3. And with automatic feeding, an unattended operation is possible, helping you to save on labor costs while reducing rejection rates.

Don’t Settle for Less, Invest in the Best with MimoWork Laser

D&R for Sublimation Polyester Laser Cutting

Outline Contour Detection

The Contour Recognition System detects the contour according to the color contrast between the printing outline and material background. No need to use the original patterns or files. After automatic feeding, printed fabrics will be directly detected. This is a fully automatic process without human intervention. Moreover, the camera will take photos after the fabric is fed to the cutting area. The cutting contour will be adjusted to eliminate deviation, deformation, and rotation, thus, you can eventually achieve a highly precise cutting result.

Template Matching

When you are trying to cut high-distortion contours or pursue super high precise patches and logos, the Template Matching System is more suitable than the contour cut. By matching your original design templates with the photos taken by the HD camera, you can easily get the exact same contour that you want to cut. Also, you can set deviation distances according to your personalized requirements.

Independent Dual Heads – Optional Upgrades

For a basic two laser heads cutting machine, the two laser heads are mounted on the same gantry, so they can not cut different patterns at the same time. However, for many fashion industries like dye sublimation apparel, for example, they may have the front, back, and sleeves of a jersey to cut. At this point, the independent dual heads can handle pieces of different patterns at the same time. This option boosts the cutting efficiency and production flexibility to the largest degree. Output can be increased from 30% to 50%.

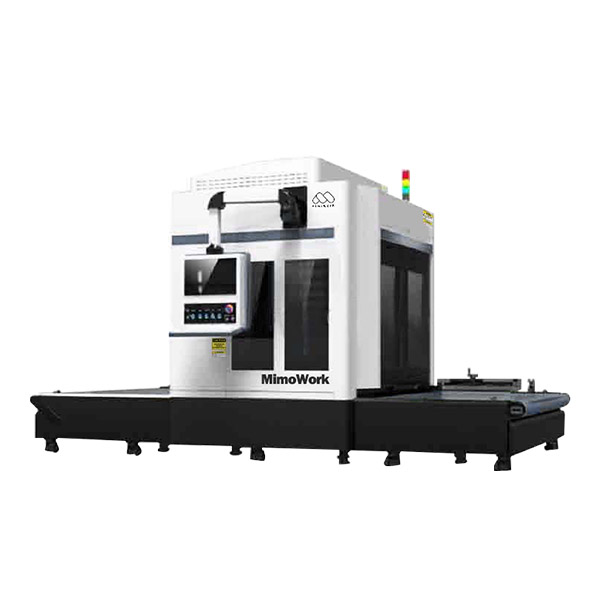

Fully Enclosure Design – Optional Upgrades

With the special design of the fully enclosed door, the Contour Laser Cutter can ensure a better exhausting and further improve the recognition effect of the HD camera to avoid vignetting that affects the contour recognition in the case of poor lighting conditions. The door on all four sides of the machine can be opened, which will not affect daily maintenance and cleaning.

<a href="https://www.mimowork.com/options/" title="Explore More Laser Machine Options” target=”_blank”>

Explore More Laser Machine Options

MimoWork is Committed to Offer Customized Laser Solution

For your Specific Demands

Enclosed Contour Laser Cutter – Video Showcase

Find more videos about our sublimation laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Sublimation Sportswear

Sublimation Sportswear

Changing the Industry with Advanced Technologies

✔ High-cutting quality, accurate pattern recognition, and fast production

✔ Meeting the needs of small-patch production for local sports team

✔ No need for cutting file

✔ The contour recognition system allows the exact cut along the printed contours

✔ Fusion of cutting edges – no need for trimming

✔ Ideal for processing stretchy and easily distorted materials

Laser Cutting Sportswear: Highlights

Making Laser Cutting Sportswear Easy & Accessible

✔ Significantly reduce the working time for orders in short delivery time

✔ The actual position and dimensions of the workpiece can be recognized exactly

✔ No material distortion thanks to the stress-free material feed and contact-less cutting

✔ Value-added laser abilities like engraving, perforating, and marking are suitable for entrepreneurs and small business

Other Materials and Applications

of Laser Cut Sportswear Machine (Fully-Enclosed)

Materials: Spandex, Cotton, Silk, Printed Velvet, Film, and other Sublimation Materials

Application: Rally Pennants, Banners, Billboards, Teardrop Flag, Leggings, Sportswear, Uniforms, Swimwear

We don’t Settle for Mediocre Results, We Aim for Perfection

Your Safety & Protection, We Provide

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for China Wholesale Large Format Dye Sub Laser Cutter Manufacturers Suppliers - Laser Cut Sportswear Machine (Fully-Enclosed) – MimoWork Laser , The product will supply to all over the world, such as: Angola , Muscat , Georgia , Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!