China Wholesale Laser Cut Acrylic Machine Factories Quotes - Contour Laser Cutter 320 – MimoWork Laser

China Wholesale Laser Cut Acrylic Machine Factories Quotes - Contour Laser Cutter 320 – MimoWork Laser Detail:

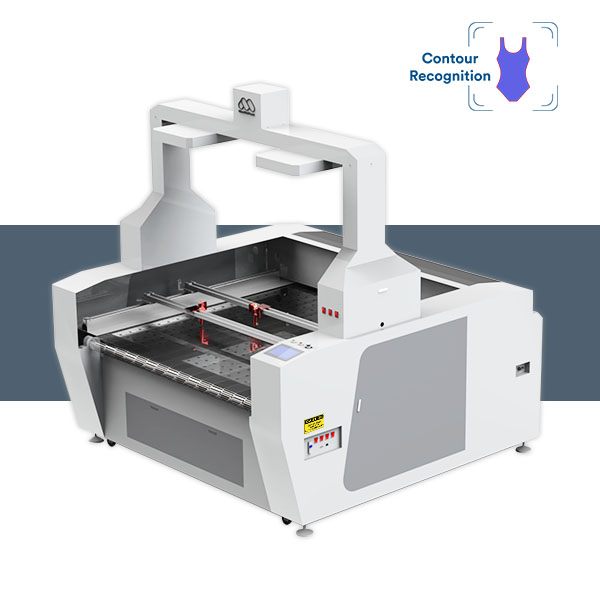

Camera Laser Cutting Machine for Large Format of Sublimation Fabrics

A Giant Leap in Productivity

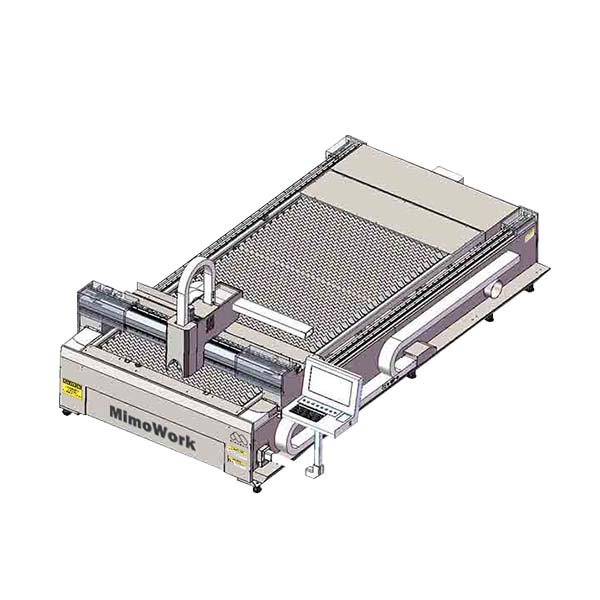

◉ Ultra-wide format fits various materials sizes

The large working area of 3200mm * 1400mm almost load all the sizes of fabrics, especially large advertising flag and signage. The sublimation laser cutter of wide breadth is an indispensable important participator in outdoor adverting and outdoor gear fields.

◉ Robust structure with long service life

Equipped with the strong & steady laser configuration and flexible transmission system, even though featuring a large body, the contour laser cutter still can flexibly cut as well as needs less maintenance for long service life.

◉ Precise pattern cutting

Sublimation fabrics and other patterned fabrics need to be accurately cut along the contour. CCD Camera Recognition System is the perfect solution cooperated with the precise laser cutting, allowing the laser head to move and cut strictly as the graphic file.

◉ Matched laser options are available

To smooth the production line and highly efficiently achieve the cutting process, we offer specialized auto-feeder to match the conveyor table, realizing auto feeding, conveying, and cutting in a short time while no need for manual intervention.

Technical Data

| Working Area (W * L) | 3200mm * 1400mm (125.9’’ *55.1’’) |

| Max Material Width | 3200mm (125.9’’) |

| Software | Offline Software |

| Laser Power | 130W |

| Laser Source | CO2 Glass Laser Tube |

| Mechanical Control System | Rack & Pinion Transmission and Step Motor Driven |

| Working Table | Conveyor Working Table |

| Cooling Mode | Constant Temperature Water Cooling |

| Electricity Supply | 220V/50HZ/single phase |

(Highlights of wide laser cutter, flag cutter, banner cutter)

R&D for Printed Fabric Laser Cutting

CCD Camera

The CCD Camera equipped next to the laser head can detect feature marks to locate the printed pattern, so as to provide instruction for the laser head’s path. The good cooperation between CCD Camera Recognition System and gantry moving ensures the accuracy of the pattern contour cutting for large format printed fabrics. o.oo1mm accuracy greatly enhances the cutting quality.

Y-axis Gear & X-axis Belt Drive

The camera laser cutting machine features a Y-axis rack & pinion Drive and X-axis belt transmission. The design offers a perfect remedy between a large format working area and smooth transmission. Y-axis rack & pinion is a type of linear actuator that comprises a circular gear (the pinion) engaging a linear gear (the rack), which operates to translate rotational motion into linear motion. The rack and the pinion drive each other spontaneously. Straight and helical gears are available for the rack & pinion. X-axis belt transmission provides a smooth and steady transmission to the laser head. High-speed and high precision laser cutting can be completed.

Auto Feeder

Auto Feeder is a feeding unit that runs synchronously with the laser cutting machine. Coordinated with conveyor table, the auto feeder can convey the roll materials to the cutting table after you put the rolls on the feeder. To match the wide format materials, MimoWork recommends the widened auto-feeder which is able to carry a bit of heavy load with large format, as well as ensure feeding smoothly. Feeding speed can be set according to your cutting speed. A sensor is equipped to ensure perfect material positioning and minimize errors. The feeder is able to attach different shaft diameters of rolls. The pneumatic roller can adapt textiles with various tension and thickness. This unit helps you to realize a completely automatic cutting process.

Vacuum Suction

The Vacuum Suction lies under the cutting table. Through the small and intensive holes on the surface of the cutting table, the air ‘fastens’ the material on the table. The vacuum table does not get in the way of the laser beam while cutting. On the contrary, together with the powerful exhaust fan, it enhances the effect of smoke & dust prevention during cutting.

Customize Your Contour Laser Cutter As Requirements

Any questions about laser cutter & options, professional technicians solve your puzzled !

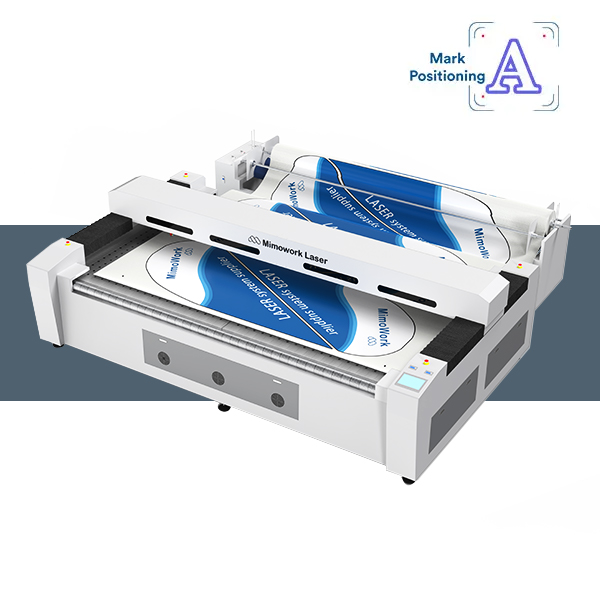

Video | How to Contour Laser Cut with CCD Camera

(Additional explanation – For more clearly show the process of CCD Camera positioning and pattern cutting for you, we put another edition of the video where the gantry and CCD Camera are exposed so you can understand easily.)

Sublimation Fabric Laser Cutting

As you can see from that, feature areas are recognized, which tells the right pattern position to the laser head so as to complete accurate contour cutting as your design file. Intelligent detection saves time and avoids errors.

In a similar war, large format of printed fabrics such as outdoor flags can be also cut along the pattern contour. Thanks to the non-contact cutting with heat treatment, clean and smooth edge is about perfect.

<a href="https://www.mimowork.com/video-gallery/" title="Source from: Video Gallery” target=”_blank”>

Source from: Video Gallery

Common materials and applications

Materials: Sublimation Fabric, Polyester, Spandex Fabric, Nylon, Canvas Fabric, Coated Fabric, Silk, Taffeta Fabric, and other printed fabrics.

Applications: Print Advertising, Banner, Signage, Teardrop Flag, Exhibition Display, Billboard, Sublimation Clothing, Home Textiles, Wall Cloth, Outdoor Equipment, Tent, Parachute, Paragliding, Kiteboard, Sail, etc.

<a href="https://www.mimowork.com/laser-cutting-print-advertising/" title="Click here to learn more [ laser cutting print advertising ]” target=”_blank”>

Click here to learn more [ laser cutting print advertising ]

Laser Cutting Printed Fabrics with Contour Laser Cutter 320140

Fields of Application

Large Advertising

Excellent cutting quality in laser cutting signs, flag, banner

✔ Flexible and efficient production solution for laser cutting outdoor advertising

✔ Benefiting from no limitation on shape, size, and pattern, customized design can be fast realized

✔ Quick response to market from samples to large-lot production

Digital Printing

The secret of exquisite pattern cutting

✔ Camera detecting and positioning save the labor while ensuring the cutting quality

✔ Sublimation print fabric can be accurately cut along the contour

✔ Auto-feeder provides the great convenience for roll fabric with a large format

✔ Combination tool with your Calendar Heat Press

Outdoor Sports Gear

Maximum materials performance for protection

The performance requirements are much higher for outdoor fabric. Like some properties of sun protection, durability, anti-abrasion, breath-ability, waterproof, wear resistance, laser cutting can protect from damage due to contactless processing. Tent, parachute, paraglider, sail, kiteboard, and other large printed equipment can all be laser cut with safe and high efficient features.

✔ High-quality value-added laser treatments

✔ Customized tables meet requirements for varieties of materials formats

FYI: If you are interested in more laser-friendly materials and applications, welcome to inquire us for your free. Or you can discover more laser magic in our materials collection and application gallery.

<a href="https://www.mimowork.com/your-business/material-overview/" title=">> Material Overview” target=”_blank”>

>> Material Overview

<a href="https://www.mimowork.com/your-business/application-overview/" title=">> Application Overview” target=”_blank”>

>> Application Overview

Large Format Cutter for Sublimation Banner, Flag for Sale

MimoWork is exploring more possibilities!

Product detail pictures:

Related Product Guide:

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of China Wholesale Laser Cut Acrylic Machine Factories Quotes - Contour Laser Cutter 320 – MimoWork Laser , The product will supply to all over the world, such as: Los Angeles , Brasilia , Malaysia , Our technical expertise, customer-friendly service, and specialized merchandise make us/company name the first choice of customers and vendors. We've been looking for your inquiry. Let's set up the cooperation right now!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!