China Wholesale Laser Cut Acrylic Machine Manufacturers Suppliers - Contour Laser Cutter 160L – MimoWork Laser

China Wholesale Laser Cut Acrylic Machine Manufacturers Suppliers - Contour Laser Cutter 160L – MimoWork Laser Detail:

Technical Data

| Working Area (W *L) | 1600mm * 1200mm (62.9” * 47.2”) |

| Max Material Width | 62.9” |

| Laser Power | 100W / 130W / 150W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Two Laser Heads option is available

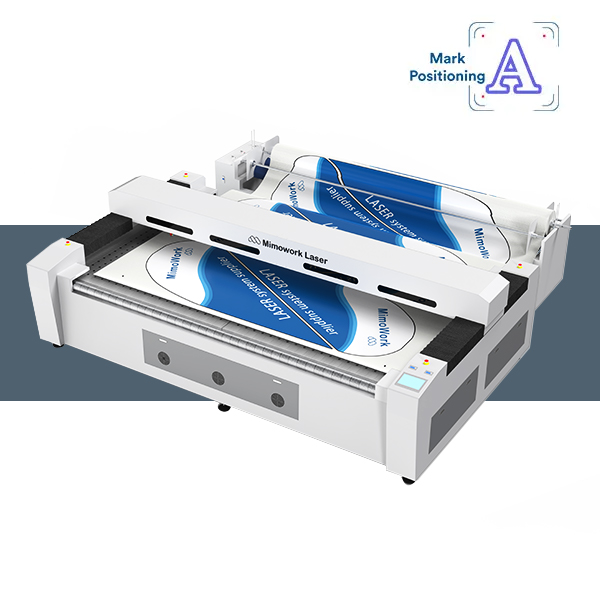

Unrivaled Choice for Dye Sublimation Laser Cutting

A Giant Leap in Productivity

◆ Wide applications in industries such as digital printing, composite materials, clothing & home textiles.

◆ Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs.

◆ Evolutionary visual recognition technology and powerful software provide higher quality and reliability for your business.

◆ Auto-feeder provides automatic feeding, allowing unattended operation which saves your labor cost, lower rejection rate (optional).

Camera laser cutting sublimation polyester, spandex, nylon, lycra, etc.

R&D for Flexible Fabric Cutting

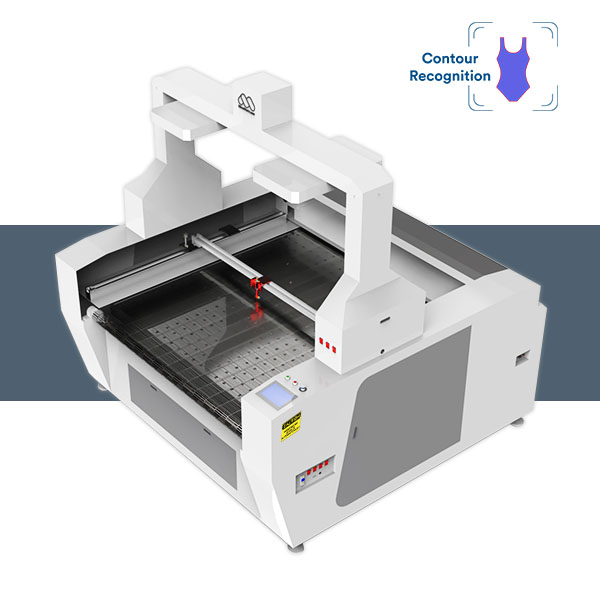

Outline Contour Detection

The Contour Recognition System detects the contour according to the color contrast between the printing outline and material background. No need to use the original patterns or files. After automatic feeding, printed fabrics will be directly detected. This is a fully automatic process without human intervention. Moreover, the camera will take photos after the fabric is fed to the cutting area. The cutting contour will be adjusted to eliminate deviation, deformation, and rotation, thus, you can eventually achieve a highly precise cutting result.

Template Matching

When you are trying to cut high distortion contours or pursue super high precise patches and logos, the Template Matching System is more suitable than the contour cut. By matching your original design templates with the photos taken by the HD camera, you can easily get the exact same contour that you want to cut. Also, you can set deviation distances according to your personalized requirements.

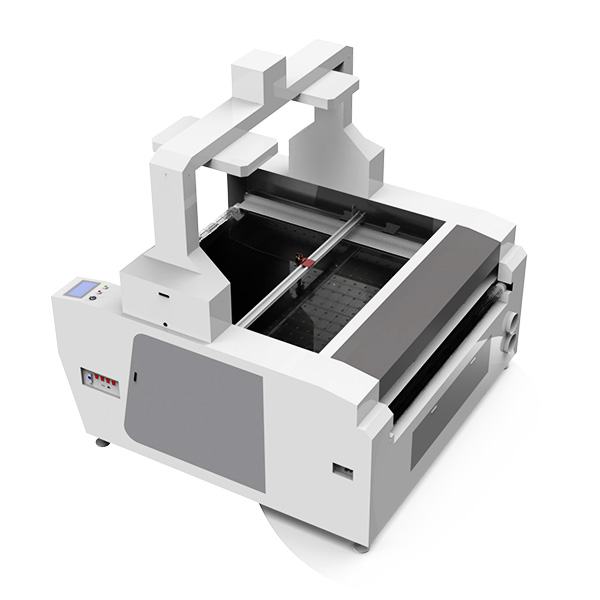

Independent Dual Heads – Option

For a basic two laser heads cutting machine, the two laser heads are mounted on the same gantry, so they can not cut different patterns at the same time. However, for many fashion industries like dye sublimation apparel, for example, they may have the front, back, and sleeves of a jersey to cut. At this point, the independent dual heads can handle pieces of different patterns at the same time. This option boosts the cutting efficiency and production flexibility to the largest degree. Output can be increased from 30% to 50%.

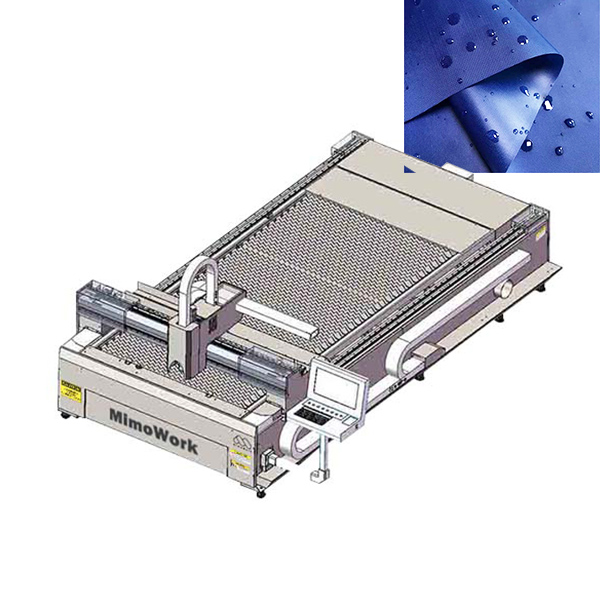

Conveyor Working Table

An increase in productivity thanks to auto-loading and unloading during the cutting process. The conveyor system is made out of stainless steel mesh, suitable for lightweight and stretchy fabrics, such as polyester fabrics and spandex, that’s commonly used in dye-sublimation fabrics. And through the specially set down exhaust system under the Conveyor Working Table, the fabric is fixed on the processing table tamely. Combined with the contact-less laser cutting, no distortion will appear despite the direction that the laser head is cutting.

Fully Enclosure Design – Option

With the special design of the fully enclosed door, the Enclosed Contour Laser Cutter can ensure a better exhausting and further improve the recognition effect of the HD camera to avoid vignetting that affects the contour recognition in the case of poor lighting conditions. The door on all four sides of the machine can be opened, which will not affect daily maintenance and cleaning.

<a href="https://www.mimowork.com/options/" title=" Upgrade your sublimation laser cutter ” target=”_blank”>

Upgrade your sublimation laser cutter

Video Demonstrations

Laser Cut Sportswear (Polyester Fabric)

<a href="https://www.mimowork.com/laser-cutting-polyester/" title=">> Laser cutting Polyester” target=”_blank”>

>> Laser cutting Polyester

Camera Laser Cut Sublimated Fabric

<a href="https://www.mimowork.com/sublimation-fabrics-laser-cutter/" title=">> Laser cutting sublimation fabric ” target=”_blank”>

>> Laser cutting sublimation fabric

How to Laser Cut Sublimation Yoga Clothes?

How to Choose Laser Machine for Fabric

<a href="https://www.mimowork.com/laser-cut-legging/" title=">> Laser cutting legging” target=”_blank”>

>> Laser cutting legging

<a href="https://www.mimowork.com/fabrics-textiles-laser-cutter/" title=">> Fabric laser cutter” target=”_blank”>

>> Fabric laser cutter

What are you gonna cut with the Camera Laser Cutter?

Fields of Application

Laser Cutting for Your Industry

Dye-Sublimation Sportswear

Vision Recognition System

✔ High cutting quality, accurate pattern recognition, and fast production

✔ Meeting the needs of small-patch production for local sports team

✔ Combination tool with your Calendar Heat Press

✔ No need for cutting file

Banners & Displays

Unique advantages of laser cutting signs & decorations

✔ Significantly reduce the working time for orders in short delivery time

✔ The actual position and dimensions of the the work piece can be recognized exactly

✔ No material distortion thanks to the stress-free material feed and contact-less cutting

✔ Ideal cutter for making exhibition stands, banners, display systems, or visual protection

Common materials and applications

of Contour Laser Cutter 160L

Materials: Polyester Fabric, Spandex, Nylon, Silk, Printed Velvet, Cotton, and other sublimation textiles

Applications: Active Wear, Sportswear (Cycling Wear, Hockey Jerseys, Baseball Jerseys, Basketball Jerseys, Soccer Jerseys, Volleyball Jerseys, Lacrosse Jerseys, Ringette Jerseys), Uniforms, Swimwear, Leggings, Sublimation Accessories (Arm Sleeves, Leg Sleeves, Bandanna, Headband, Face Cover, Masks)

Automated Options: Enhance the Workflow

MimoWork highly recommends the use of laser cutters with automated options to enhance the cutting workflow in sportswear production. Specifically designed for cutting complete rolls of dye-sublimated materials, these laser cutters minimize the need for operator intervention, allowing them to oversee other processes concurrently. Key advantages of MimoWork laser cutters include:

Advanced Camera System:

MimoWork laser cutters feature a cutting-edge camera system that rapidly scans materials, promptly identifying and automatically compensating for any deformations in the cutting vector. This not only saves time but also ensures precision.

Motorized De-reeler with Edge Detection:

The included motorized de-reeler comes with an edge-detection option, preventing fabric distortion during the cutting process. By relaxing the material and maintaining a constant and straight feed, this feature guarantees accuracy even at high cutting speeds.

Large-Format Vision Laser Cutter 160L:

The 160L stands out for its speed, thanks to the innovative on-the-fly concept. This involves capturing the design, automatically creating the cut design, and initiating cutting while the next part is being scanned. The 160L significantly boosts productivity compared to other cutting solutions available in the market.

High Laser Acceleration:

The lightweight head housing the laser beam enables high laser acceleration, contributing to the efficiency of the cutting process.

You Might be Interested in:

The Realm of Laser Cut Cordura: Cordura Fabric

Laser Engraved Gifts | Best of 2023 Christmas

Performance Report: Laser Cut Sportswear Machine

Sublimation Laser Cutter has served doze of clients

Add yourself to the list!

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for China Wholesale Laser Cut Acrylic Machine Manufacturers Suppliers - Contour Laser Cutter 160L – MimoWork Laser , The product will supply to all over the world, such as: Malaysia , New Zealand , Kuwait , The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we will continue with the most professional and high quality service to provide the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.