China Wholesale Laser Cut Card Factories Quotes - Industrial Laser Cutter for Fabric – MimoWork Laser

China Wholesale Laser Cut Card Factories Quotes - Industrial Laser Cutter for Fabric – MimoWork Laser Detail:

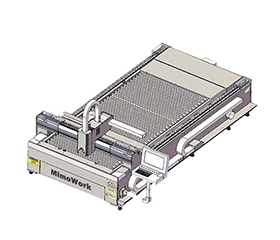

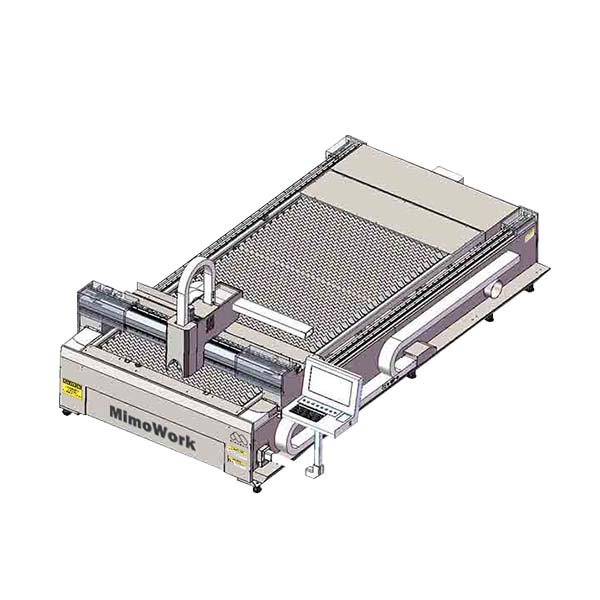

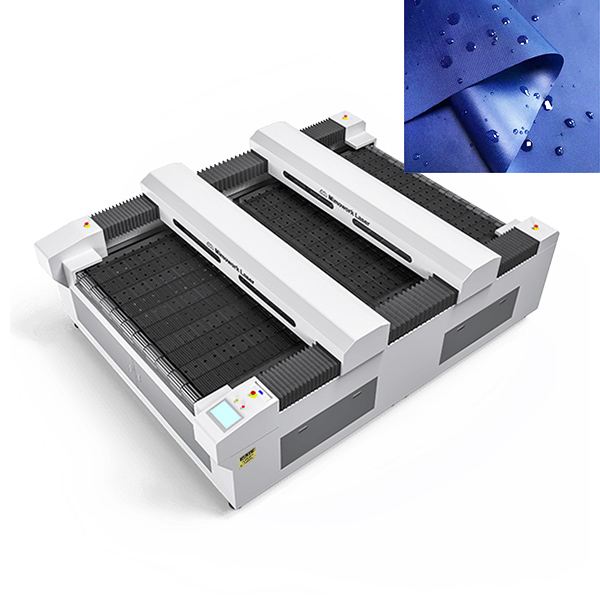

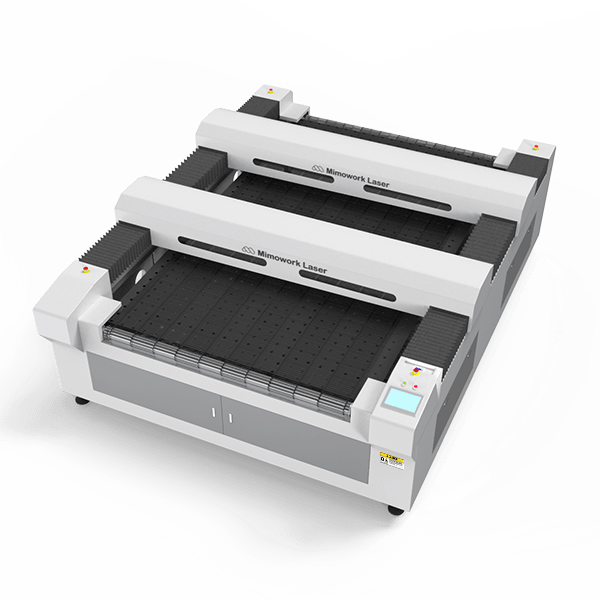

▶ Industrial fabric laser cutting machine

Technical Data

| Working Area (W * L) | 1600mm * 3000mm (62.9’’ *118’’) |

| Max Material Width | 1600mm (62.9’’) |

| Software | Offline Software |

| Laser Power | 150W/300W/500W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Rack & Pinion Transmission and Servo Motor Driven |

| Working Table | Conveyor Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

* Two independent laser gantries are available to double your efficiency.

Mechanical Structure

▶ High Efficiency & High Output

▶ Excellent Cutting Quality

▶ Safe & Stable Structure

R&D for Flexible Material Cutting

CO2 RF Laser Source – Option

Combines power, excellent beam quality, and nearly square wave pulses (9.2 / 10.4 / 10.6μm) for high processing efficiency and speed. With small heat-affected zone, plus compact, fully sealed, slab discharge construction for enhanced reliability. For some special industrial fabrics, RF Metal Laser Tube will be a better option.

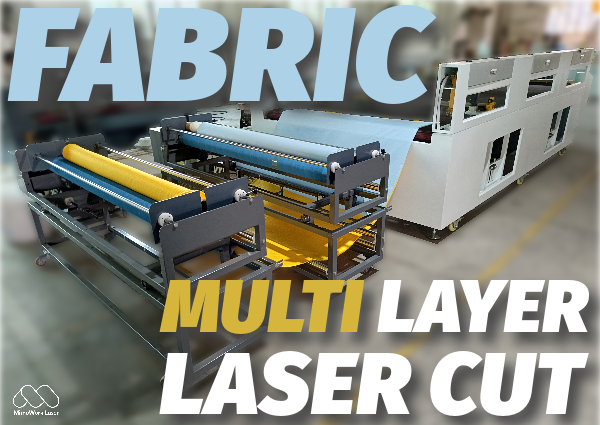

Auto Feeding System

The Auto Feeder combined with the Conveyor Table is the ideal solution for series and mass production. It transports the flexible material (fabric most of the time) from the roll to the cutting process on the laser system. With stress-free material feeding, there is no material distortion while contactless cutting with laser ensures outstanding results.

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further manual intervention.

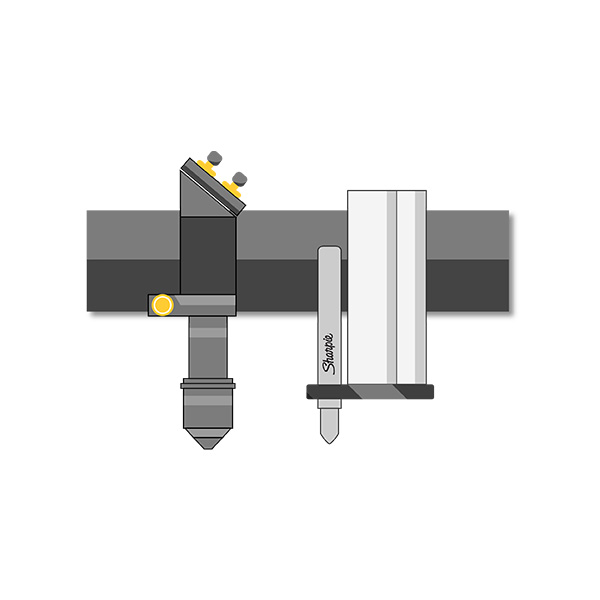

Marker Pen Module

You can use the marker pen to make the marks on the cutting pieces, enabling the workers to sew easily. You can also use it to make special marks such as the serial number of the product, the size of the product, the manufacture date of the product, etc.

Ink-jet Print Module

It is widely used commercially for marking and coding products and packages. A high-pressure pump directs liquid ink from a reservoir through a gun body and a microscopic nozzle, creating a continuous stream of ink droplets via the Plateau-Rayleigh instability. Different inks are optional for specific fabrics.

Video Example: Cut & Mark Fabric for Sewing with Laser

Fabric Samples from Large Fabric Cutter

Video Display

Source from: Video Gallery

Cordura Fabric Laser Cutting

— protective vest

◆ Cutting through the fabric at one time, no adhesion

◆ No thread residue, no burr

◆ Flexible cutting for any shapes and sizes

Laser-friendly Fabrics:

nylon, aramid, Kevlar, Cordura, denim, filter cloth, fiberglass, polyester, felt, EVA, coated fabric, etc.

Pictures Browse

How Much is an Industrial Laser Cutter for Fabric?

The cost of an industrial laser cutter for fabric can vary widely depending on several factors, including the model, size, CO2 laser type (glass laser tube or RF laser tube), laser power, cutting speed, and additional features. Industrial laser cutters for fabric are designed for high-volume and precision cutting applications.

Here are Some Approximate Price Ranges for Industrial Laser Cutters for Fabric:

1. Entry-Level Industrial Laser Cutters:

These machines come with small fixed working tables, and typically start at around $3,000 to $4,500. They are suitable for small to medium-sized businesses with moderate cutting needs from fabric piece to piece.

2. Mid-Range Industrial Laser Cutters:

Mid-range models with larger working areas, higher laser powers, and more advanced features can range from $4,500 to $6,800. These machines are suitable for medium businesses with higher production volumes.

3. High-End Industrial Laser Cutters:

Larger, high-power and fully automated industrial laser cutters can range from $6,800 to over a million dollars. These machines are designed for large scale manufacturing and can handle heavy-duty cutting tasks.

4. Custom and Specialized Machines:

If you require highly specialized features, custom-built machines, or laser cutters with unique capabilities, the price can vary significantly.

In Addition to the Initial Machine Cost:

It’s important to consider other expenses such as installation, training, maintenance, and any necessary software or accessories. Keep in mind that the cost of operating the laser cutter, including electricity and maintenance, should also be factored into your budget.

To get an accurate quote for an industrial laser cutter for fabric that suits your specific requirements, it’s recommended to contact MimoWork Laser directly, provide them with detailed information about your needs, and request a customized quote. Consulting MimoWork Laser will help you make an informed decision and choose the best laser cutter for your business.

Related Fabric Laser Cutters

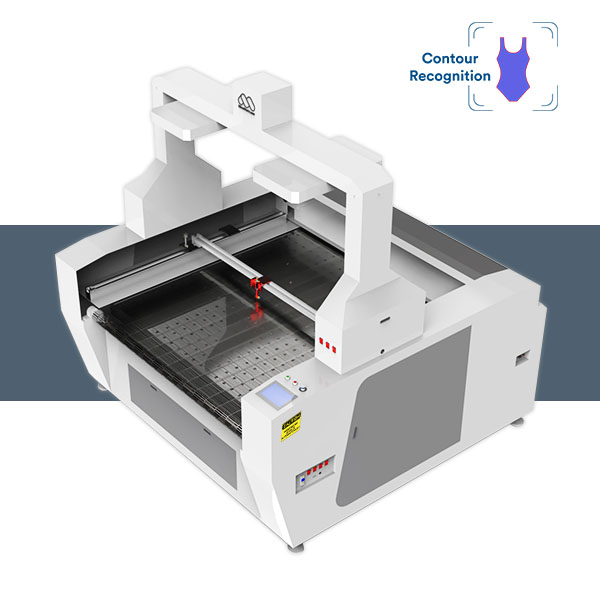

Laser Fabric Cutter

• Laser Power: 100W / 150W / 300W

• Working Area (W *L): 1600mm * 1000mm

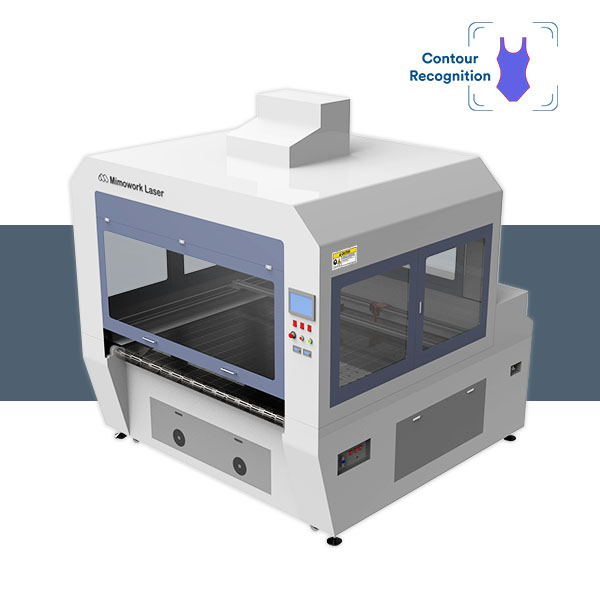

Textile laser cutting machine (fabric)

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1800mm * 1000mm

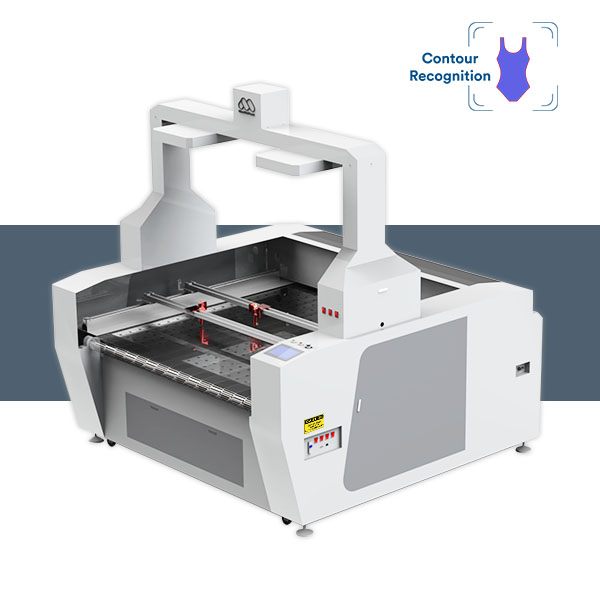

Commercial Laser Cutter for Fabric

• Laser Power: 150W/300W/500W

• Working Area (W *L): 1600mm * 3000mm

Related Articles

Laser Cut Vinyl – A Few More Things

The Art of CO2 Laser Fabric Perforation

Unleash the Cutting Power with Multi-Layer Laser Cut

We’ve designed laser systems for dozens of clients

Pick your fabric laser cutter

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for China Wholesale Laser Cut Card Factories Quotes - Industrial Laser Cutter for Fabric – MimoWork Laser , The product will supply to all over the world, such as: Riyadh , Hanover , Vietnam , We have many years' experience in hair product production, and our strict QC Team and skilled workers will ensure that we give you top hair products with the best hair quality and workmanship. You will get successful business if you choose to cooperate with such a professional manufacturer. Welcome your order cooperation!

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.