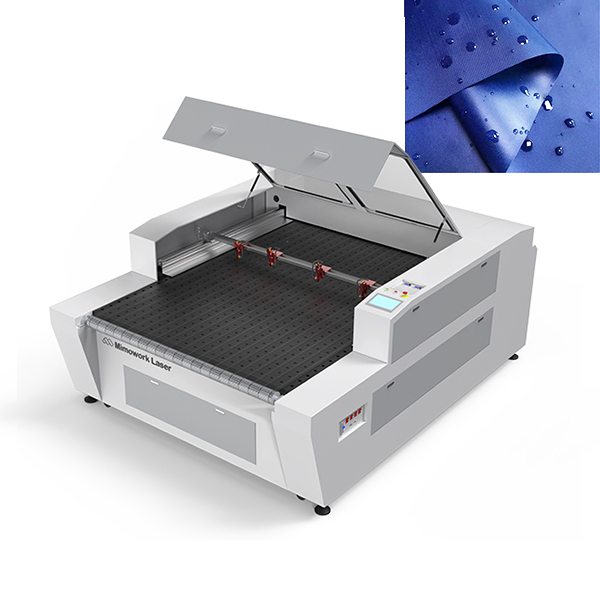

China Wholesale Laser Cut Gift Manufacturers Suppliers - Flatbed Laser Cutter 180 – MimoWork Laser

China Wholesale Laser Cut Gift Manufacturers Suppliers - Flatbed Laser Cutter 180 – MimoWork Laser Detail:

Advantages of Textile Laser Cutting Machine

Marking all over your place

◉ Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Mark pen makes labor-saving process and efficient cutting & marking operations possible

◉ Upgraded cutting stability and safety – improved by adding the vacuum suction function

◉ Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional)

◉ Advanced mechanical structure allows laser options and customized working table

Technical Data

| Working Area (W * L) | 1800mm * 1000mm (70.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

(Upgrade Power for your laser cutting machine for textile garment)

R&D for Textile and Fabric Laser Cutting

Two Laser Heads

In the simplest and most economic way to double your efficiency is to mount two laser heads on the same gantry and cut the same pattern at the same time. This doesn’t take extra space or labor. If you need to cut a lot of repeat patterns, this would be a good choice for you.

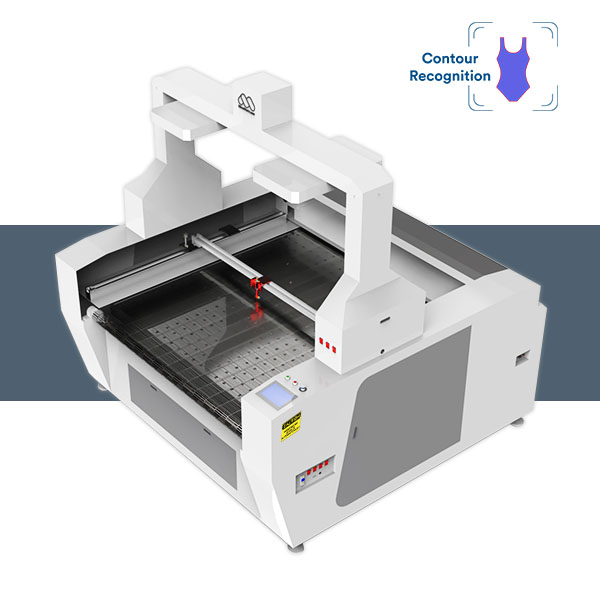

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

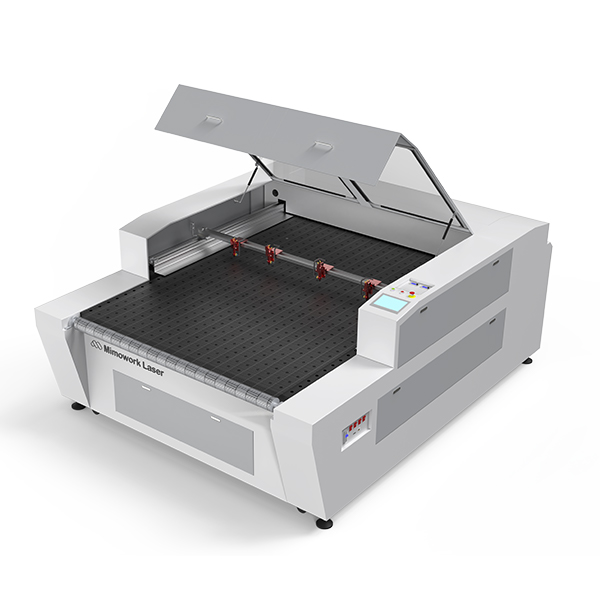

Conveyor Table

The Conveyor System is the ideal solution for series and mass production. The combination of the Conveyor table and the auto feeder provides the easiest production process for cut roll materials. It transports the material from the roll to the machining process on the laser system.

Video Glance

▷ How to laser cut cotton fabric

✔ Automatic feeding, conveying and cutting can be achieved

✔ Dual laser heads is optional to further enhance the efficiency

✔ Flexible cotton cutting according to the uploaded graphic file

✔ Non-contact and heat treatment ensure the clean and flat cutting quality

<a href="https://www.mimowork.com/laser-cut-cotton-fabric/" title=">> learn more cotton laser cutting” target=”_blank”>

>> learn more cotton laser cutting

Find more videos about our laser cutters at our Video Gallery

▷ Cutting sandpaper with the laser cutter

Powerful laser beam release huge energy to melt the sandpaper instantly. Non-contact laser cutting avoid the touch between sandpaper and laser head, leading to clean and crisp cutting effect. Also, with the Nesting software and Mimocut software, shortest time-consuming and minimum material-waste become possible. As you can see on the video, accurate shape cutting can be consistent to complete the whole production.

<a href="https://www.mimowork.com/laser-cutting-sandpaper/" title=">> learn more laser cutting sandpaper” target=”_blank”>

>> learn more laser cutting sandpaper

Fields of Application

Laser Cutting for Your Industry

Clothing & Home Textiles

✔ Smooth and lint-free edge through heat treatment

✔ Conveyor system helps more efficient production for the roll materials

✔ High precision in cutting, marking, and perforating with fine laser beam

Composite Material

Engraving, marking, and cutting can be realized in single process

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

✔ Fewer material waste, no tool wear, better control of production costs

✔ Ensures a safe working environment during operation

✔ High precision in cutting, marking, and perforating with fine laser beam

From MimoWork Advice:

Roll fabric and leather products all can be laser cut and laser engraved. MimoWork provides the professional technology support and considerate reference guide. Reliable quality and caring service are the aim we are committed to. Also, evolving materials and application adaptable to laser cutting is expanding. You can find your material or application on our MimoWork Lab-Base.

Materials Overview

Application Overview

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for China Wholesale Laser Cut Gift Manufacturers Suppliers - Flatbed Laser Cutter 180 – MimoWork Laser , The product will supply to all over the world, such as: Congo , France , Denmark , Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!