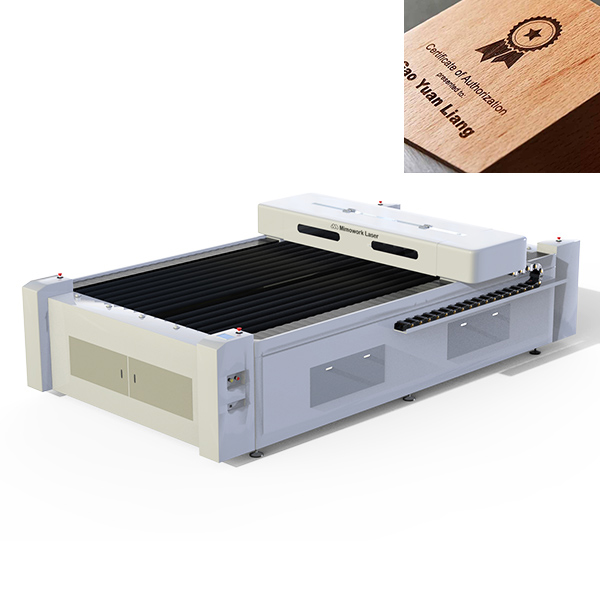

China Wholesale Laser Cut Lgp Quotes Pricelist - CO2 Laser Cutting Machine for Thick Wood (Up to 30mm) – MimoWork Laser

China Wholesale Laser Cut Lgp Quotes Pricelist - CO2 Laser Cutting Machine for Thick Wood (Up to 30mm) – MimoWork Laser Detail:

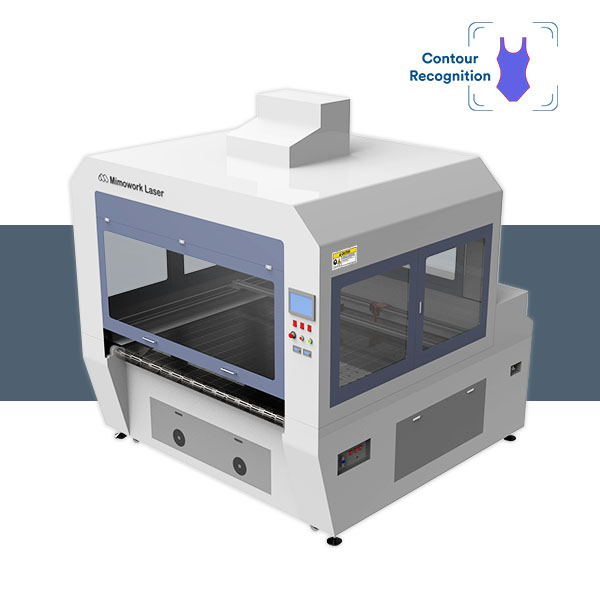

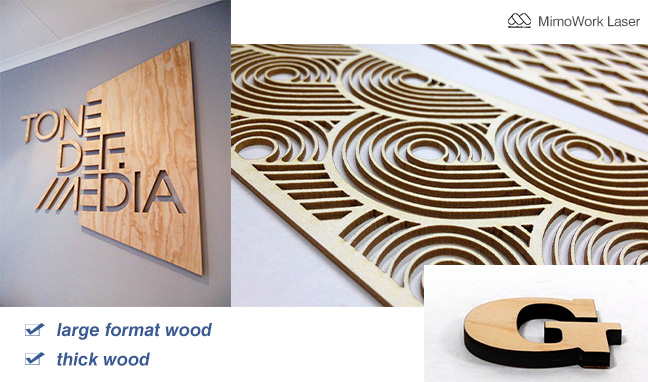

▶ Large format laser cutter for wood

Technical Data

|

Working Area (W * L) |

1300mm * 2500mm (51” * 98.4”) |

|

Software |

Offline Software |

|

Laser Power |

150W/300W/500W |

|

Laser Source |

CO2 Glass Laser Tube |

|

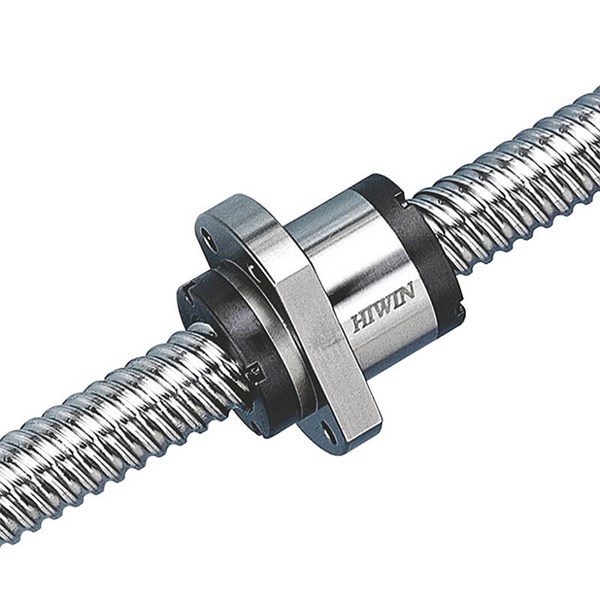

Mechanical Control System |

Ball Screw & Servo Motor Drive |

|

Working Table |

Knife Blade or Honeycomb Working Table |

|

Max Speed |

1~600mm/s |

|

Acceleration Speed |

1000~3000mm/s2 |

|

Position Accuracy |

≤±0.05mm |

|

Machine Size |

3800 * 1960 * 1210mm |

|

Operating Voltage |

AC110-220V±10%,50-60HZ |

|

Cooling Mode |

Water Cooling and Protection System |

|

Working Environment |

Temperature:0—45℃ Humidity:5%—95% |

|

Package Size |

3850mm * 2050mm *1270mm |

|

Weight |

1000kg |

▷ Features of 1325 Laser Cutter

A Giant Leap in Productivity

◾ Stable & excellent cutting quality

◾ High efficiency and precision

◾ Durable and long service life

◾ High speed processing

Why choose MimoWork Laser

130250 laser machine details comparison

|

|

Other manufacturer’s |

MimoWork laser machine |

|

Cutting speed |

1-15,000mm/min |

1-36,000mm/min |

|

Position accuracy |

≤±0.2mm |

≤±0.05mm |

|

Laser power |

80W/100W/130W/150W |

100W/130W/150W/300W/500W |

|

Laser path |

Half-fly laser path |

Constant optical path |

|

Transmission system |

Transmission belt |

Servo motor + ball screw |

|

Driving system |

Step driver |

Servo motor |

|

Control system |

Old system, out of the sale |

New popular RDC control system |

|

Optional electrical design |

No |

CE/UL/CSA |

|

Main body |

Traditional welding fuselage |

Reinforced bed, the overall structure is welded with 100mm square tube, and undergoes vibration aging and natural aging treatment. |

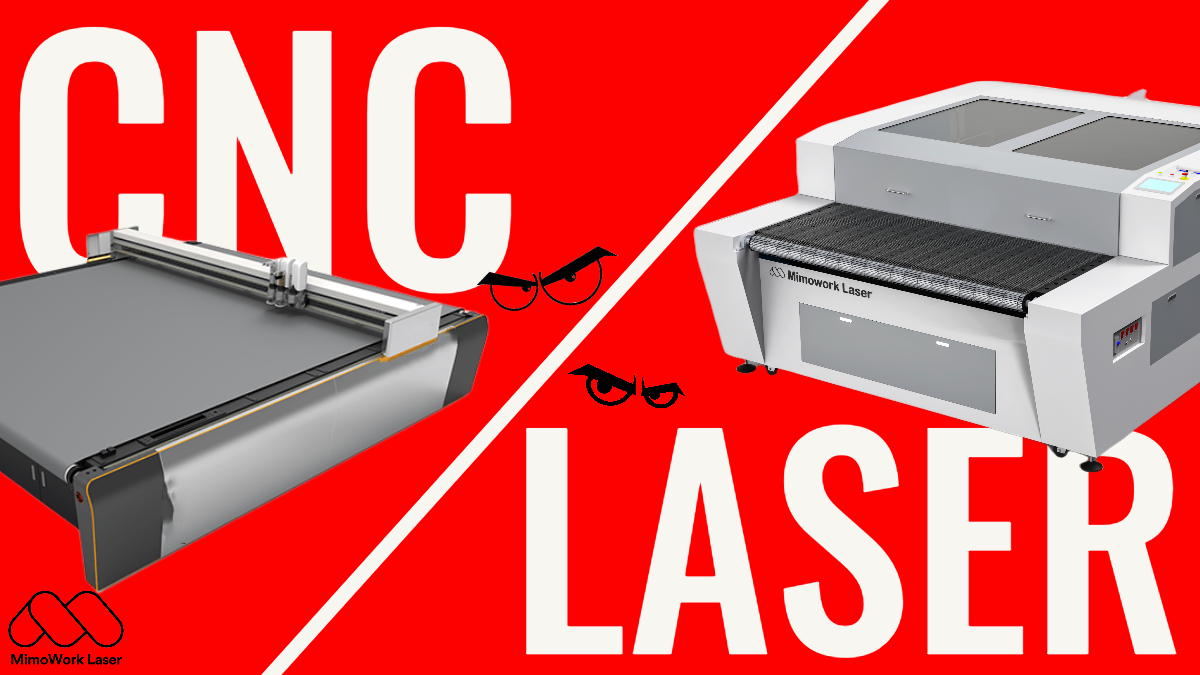

Wood Cutting: CNC Routers VS Laser

1. Advantages & Disadvantages of CNC Routers

Historically, one of the primary benefits of opting for a router as opposed to a laser was its ability to achieve precise cutting depths. A CNC router offers the convenience of vertical adjustments (along the Z-axis), allowing for straightforward control over the depth of the cut. In simpler terms, you can adjust the cutter’s height to selectively remove only a portion of the wood’s surface.

Routers excel in handling gradual curves but have limitations when it comes to sharp angles. The precision they offer is constrained by the radius of the cutting bit. In simple terms, the width of the cut corresponds to the size of the bit itself. The smallest router bits typically have a radius of approximately 1 mm.

Since routers cut through friction, it’s crucial to securely anchor the material to the cutting surface. Without proper fixation, the router’s torque can result in the material spinning or shifting abruptly. Typically, wood is fastened in place using clamps. However, when a high-speed router bit is applied to tightly-clamped material, significant tension is generated. This tension has the potential to warp or harm the wood, presenting challenges when cutting very thin or delicate materials.

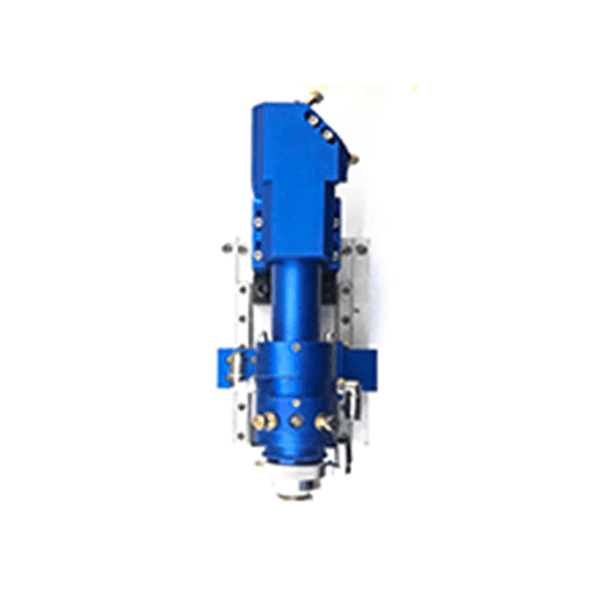

2. Advantages & Disadvantages of Laser

Similar to automated routers, laser cutters are controlled by a CNC (Computer Numerical Control) system. However, the fundamental distinction lies in their method of cutting. Laser cutters do not rely on friction; instead, they cut through materials using intense heat. A high-energy light beam effectively burns through wood, as opposed to the traditional carving or machining process.

As previously noted, the width of a cut is determined by the size of the cutting tool. While the smallest router bits have a radius of slightly less than 1 mm, a laser beam can be adjusted to have a radius as small as 0.1 mm. This capability allows for the creation of extremely intricate cuts with remarkable precision.

Because laser cutters utilize a burning process to cut through wood, they yield exceptionally sharp and crisp edges. Although this burning can lead to some discoloration, measures can be implemented to prevent undesired burn marks. Additionally, the burning action seals the edges, thereby minimizing the expansion and contraction of the cut wood.

Samples From Wood Laser Cutter

<a href="https://www.mimowork.com/laser-cutting-wood/" title=">> Learn more wood laser cutting” target=”_blank”>

>> Learn more wood laser cutting

Suitable wood materials

MDF, Basswood, White Pine, Alder, Cherry, Oak, Baltic Birch Plywood, Balsa, Cork, Cedar, Balsa, Solid Wood, Plywood, Timber, Teak, Veneers, Walnut, Hardwood, Laminated Wood and Multiplex

Wide applications

Videos | What can the Laser Machine do for you

Laser Cutting Plywood (7 layers)

Laser Cutting 21mm Thick Acrylic

▶ Large format laser cutter for wood

Upgrade Options for you to choose

Auto Focus

It is mainly used for metal cutting. You may need to set a certain focus distance in the software when the cutting material is not flat or with different thicknesses. Then the laser head will automatically go up and down, keeping the same height & focus distance to match with what you set inside the software to achieve a consistently high cutting quality.

CCD Camera

The CCD Camera can recognize and position the pattern on the printed acrylic, assisting laser cutter to realize accurate cutting with high quality. Any customized graphic design printed can be flexibly processed along the outline with the optical system, playing an important part in advertising and other industry.

Related Laser Machine

for wood and acrylic laser cutting

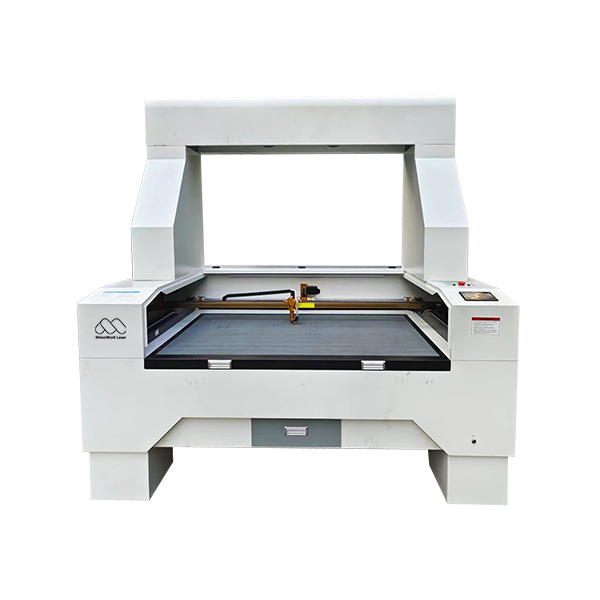

<a href="https://www.mimowork.com/flatbed-laser-cutting-machine/laser-engraving-machine-for-wood.html" title="Flatbed Laser Cutter 130” target=”_blank”>

Flatbed Laser Cutter 130

• Fast & precise engraving for solid materials

• Two-way penetration design allows ultra-long materials placed and cut

for wood and acrylic laser engraving

<a href="https://www.mimowork.com/flatbed-laser-cutting-machine/desktop-laser-engraver-70.html" title="Desktop Laser Engraver 70” target=”_blank”>

Desktop Laser Engraver 70

• Light and compact design

• Easy to operate for beginners

Achieve your laser cutter wood designs

Click here to learn the wood laser cutting machine price

Product detail pictures:

Related Product Guide:

abide by the contract, conforms to the market requirement, joins during the market competition by its superior quality also as provides extra comprehensive and exceptional service for consumers to let them turn into significant winner. The pursue of the business, is definitely the clients' gratification for China Wholesale Laser Cut Lgp Quotes Pricelist - CO2 Laser Cutting Machine for Thick Wood (Up to 30mm) – MimoWork Laser , The product will supply to all over the world, such as: Norwegian , Lisbon , St. Petersburg , Our company, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.