China Wholesale Laser Cut Natural Fibers Quotes Pricelist - Flatbed Laser Cutter 160 with extension table – MimoWork Laser

China Wholesale Laser Cut Natural Fibers Quotes Pricelist - Flatbed Laser Cutter 160 with extension table – MimoWork Laser Detail:

Quick Overview ⇨

What is Extension Table Laser Cutter?

▶ High Efficiency – collecting while cutting

▶ Versatile Use – cut pieces longer than working table

Advantages of Laser Cloth Cutting Machine

A Giant Leap in Productivity

◉ Innovative mechanical structure of extension table provides convenience for collecting finished pieces

◉ Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Mark pen makes labor-saving process and efficient cutting & marking operations possible

◉ Upgraded cutting stability and safety – improved by adding the vacuum suction function

◉ Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional)

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Collecting Area (W * L) | 1600mm * 500mm (62.9” * 19.7”) |

| Software | Offline Software |

| Laser Power | 100W / 150W / 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive / Servo Motor Drive |

| Working Table | Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

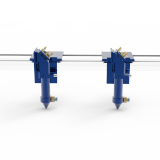

* Multiple Laser Head option available

(as your fabric laser cutter machine, cloth laser cutter, garment laser cutting machine, leather laser cutter)

R&D for Fabric and Cloth Laser Cutting

Two Laser Heads – Option

In the simplest and most economic way to double your efficiency is to mount two laser heads on the same gantry and cut the same pattern at the same time. This doesn’t take extra space or labor. If you need to cut a lot of repeat patterns, this would be a good choice for you.

Nesting Software – Option

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

Ink-Jet Printing

Ink-Jet Printing is widely used for marking and coding products and packages. A high-pressure pump directs liquid ink from a reservoir through a gun-body and a microscopic nozzle, creating a continuous stream of ink droplets via the Plateau-Rayleigh instability. The ink-jet printing technology is a non-contact process and has a wider application in terms of different types of materials. Moreover, inks are also options, like volatile ink or non-volatile ink, MimoWork loves to help to choose according to your needs.

Fume Extractor – Option

Melting the surface of the material to achieve the perfect cutting result, CO2 laser processing may generate lingering gases, pungent odor, and airborne residues when you are cutting synthetic chemical materials and the CNC router can’t deliver the same precision that laser does. MimoWork Laser Filtration System can help one puzzle out the bothersome dust and fumes while minimizing disruption to production.

Video Display – Laser Cutting Industrial Fabric

<a href="https://www.mimowork.com/video-gallery/" title="Source from: Video Gallery” target=”_blank”>

Source from: Video Gallery

<a href="https://www.mimowork.com/laser-cutting-foam/" title="Click here to learn more [ laser cutting foam ]” target=”_blank”>

Click here to learn more [ laser cutting foam ]

<a href="https://www.mimowork.com/laser-cutting-felt/" title="Click here to learn more [ laser cutting felt ]” target=”_blank”>

Click here to learn more [ laser cutting felt ]

Fields of Application

Laser Cutting for Your Industry

Clothing & Home Textiles

✔ Standardized production of each piece of cloth cutting with the benefit of CNC control drive

✔ Smooth and lint-free edge through heat treatment

✔ High precision in cutting, marking, and perforating with fine laser beam

Composite Material

Engraving, marking, and cutting can be realized in single process

✔ High precision in cutting, marking, and perforating with fine laser beam

✔ Fewer material waste, no tool wear, better control of production costs

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

✔ Multiple Usage – One laser cutter can process variety of composite materials

Automotive & Aviation

Your popular and wise manufacturing direction

✔ Smooth and lint-free edge through heat treatment

✔ High quality brought by fine laser beam and contactless processing

✔ Greatly saving cost in materials waste

Outdoor Equipment

The secret of exquisite pattern cutting

✔ Realize unattended cutting process, reduce manual workload

✔ High-quality value-added laser treatments like engraving, perforating, marking, etc Mimowork adaptable laser ability, suitable to cut diverse materials

✔ Customized tables meet requirements for varieties of materials formats

Common materials and applications

of Flatbed Laser Cutter 160

Materials: Fabric, Leather, Fleece, Film, Foil, Line Fabric, Sorona, Canvas, Velcro, Silk, Spacer Fabric, and other Non-metal Materials

Applications: Garment, Footwear, Toys, Filtration, Car Seat, Air Bag, Clothing Accessories, and many others

View all materials

View all applications

Most suitable laser configuration and fabric laser cutter price

Let’s know your requirements!

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for China Wholesale Laser Cut Natural Fibers Quotes Pricelist - Flatbed Laser Cutter 160 with extension table – MimoWork Laser , The product will supply to all over the world, such as: Swaziland , South Korea , Sydney , We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!