China Wholesale Laser Cut Paper Manufacturers Suppliers - Perforated Fabric Laser Machine – MimoWork Laser

China Wholesale Laser Cut Paper Manufacturers Suppliers - Perforated Fabric Laser Machine – MimoWork Laser Detail:

▷ What is a galvo laser?

▷ How does laser perforation work?

Video Display

Laser Perforating for Sportswear

✦ Improve the breathability of clothing (especially for sportswear)

✦ Enrich the appearance, build the brand style

✦ Customize diverse holes shapes and layouts

(Superior Specifications for your fabric laser hole cutting, fabric laser engraving and laser marking )

Technical Data

|

Working Area (W * L) |

1600mm * 800mm (62.9” * 31.5 ”) |

|

Beam Delivery |

3D Galvanometer |

|

Laser Power |

130W |

|

Laser Source |

CO2 Glass Laser Tube |

|

Laser Head |

Galvanometer Head & X-Y Cutting Head |

|

Mechanical System |

Step Motor, Belt Driven |

|

Working Table |

Honey Comb Working Table, Conveyor Table |

|

Max Cutting Speed |

1~1000mm/s |

|

Max Marking Speed |

1~10,000mm/s |

|

Perforation Speed |

13,000 holes/3min |

Advantages from Fabric Laser Perforation Machine

Structure Features

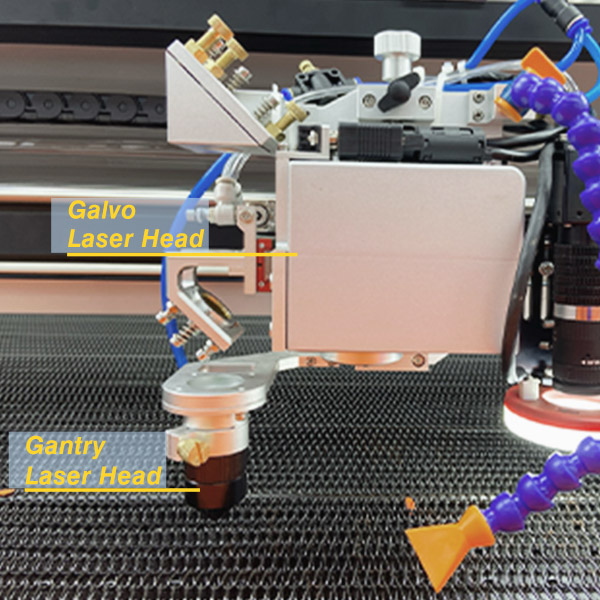

Galvo Laser Head & Gantry Laser Head

Equipped with the galvo and gantry laser heads, the laser machine is so versatile to wear many hats that it can realize laser cutting, laser perforating, laser engraving, and laser marking on fabrics, leather, and other industrial materials. Possessing the steady laser cutting of the X-Y axis, fast and uniform laser perforating, and sophisticated engraving from flying galvo laser head, the laser machine is widely used in sportswear fabric perforating and garment accessories processing.

Highlights of the Perforated Fabric Laser Machine

High Efficiency:

Laser perforating and laser cutting can be realized on one machine. With the combination of the galvo laser head and gantry laser head, you can complete the production with consistent & fast galvo perforation of 13,000 holes/3 min, as well as gantry laser cutting without splicing problem.

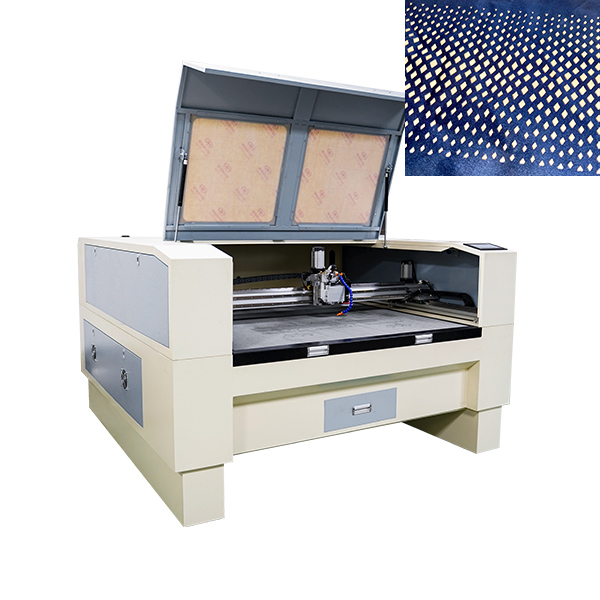

Multiple Applications:

It’s so convenient for the fabric laser perforating and cutting like fashion and sportswear. Sheet and roll fabric can be all uploaded on the working table and be laser processed. You can first laser perforation and then start fabric laser cutting. If only laser perforated fabric, that’s also accessible.

Stable and Safe Structure:

The stable honey comb table guarantees the materials flat and consistent & premium finished effects from laser perforating, cutting, and engraving. MimoWork Laser is proud of reliable and stable quality with the CE Certification.

Flexible and Customized Design:

Any holes layouts, shapes, and diameters can be customized and adjusted before importing the graphic file. You can easily realize the design of specific styles as well as enhance the breathability thanks to the flexible laser perforating and laser cutting without pattern limitation.

Upgrade from the Laser Perforating and Cutting Machine

Auto Feeder

Auto Feeder delivers continuous and automatic materials feeding to the working table. For the roll fabric and leather, it can always ensure the flatness and smoothness of the material until laser perforating and laser cutting. Saving labor and time.

Conveyor System

The Conveyor System is the ideal solution for series and mass production. The combination of the conveyor table and the auto feeder provides the easiest production process for cut coiled materials. It transports the material from the roll to the machining process on the laser system.

<a href="https://www.mimowork.com/working-table/" title=">> Check out other laser cutter table” target=”_blank”>

>> Check out other laser cutter table

CCD Camera

The CCD Camera can recognize and position the pattern on the printed fabric, assisting the galvo & gantry laser machine to realize accurate pattern cutting with high quality after laser perforation. For some sublimation sportswear, the customized graphic design printed can be flexibly laser cut along the outline with the optical system.

Befitting laser configuration means optimal productive efficiency

<a href="https://www.mimowork.com/fabric-laser-perforation/" title="Source from: fabric laser perforation” target=”_blank”>

Source from: fabric laser perforation

Samples Glance

• Perforated Leather Motorcycle Gloves

• Perforated Sportswear (perforated legging)

• Perforated Curtain…

Except for the perforated fabric and perforated leather used in garments, home textiles and footwear, the perforated fabric laser machine can also laser perforate on the car seat, fabric duct, film, patch, and some garment accessories. You may not expect that the laser perforation driver’s license can be even achieved by the galvo laser machine. Also, due to the fine laser beam and high speed, intricate laser engraving on the denim, paper, felt, fleece and nylon is available with the galvo & gantry laser machine.

Related Laser Machine

Galvo Laser Engraver & Marker 40

• Laser Power: 180W/250W/500W

• Working Area: 400mm * 400mm (15.7” * 15.7”)

Galvo Laser Engraver 80

• Laser Power: 250W/500W

• Working Area: 800mm * 800mm (31.4” * 31.4”)

Galvo Laser Marking Machine

• Laser Power: 350W

• Working Area: 1600mm * Infinity (62.9″ * Infinity)

Learn more about what is a galvo laser, fabric laser perforation machine, MimoWork is here to help you!

Product detail pictures:

Related Product Guide:

go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for China Wholesale Laser Cut Paper Manufacturers Suppliers - Perforated Fabric Laser Machine – MimoWork Laser , The product will supply to all over the world, such as: Canada , Vietnam , Kuwait , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.