China Wholesale Laser Cutter For Fabric Factories Quotes - Laser Fabric Cutter – MimoWork Laser

China Wholesale Laser Cutter For Fabric Factories Quotes - Laser Fabric Cutter – MimoWork Laser Detail:

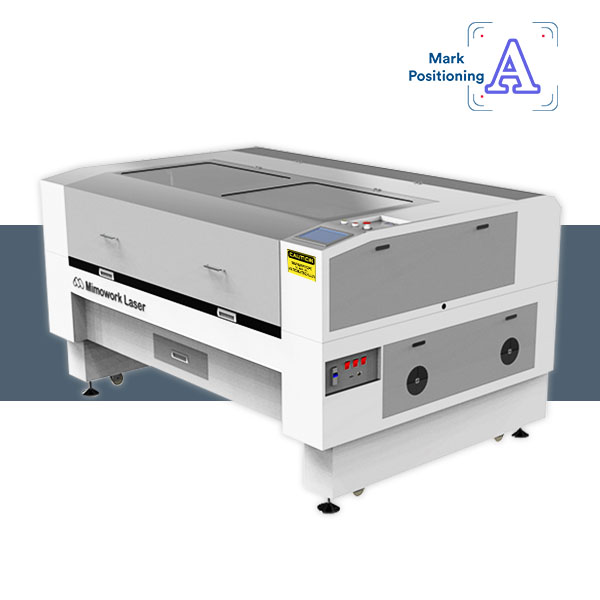

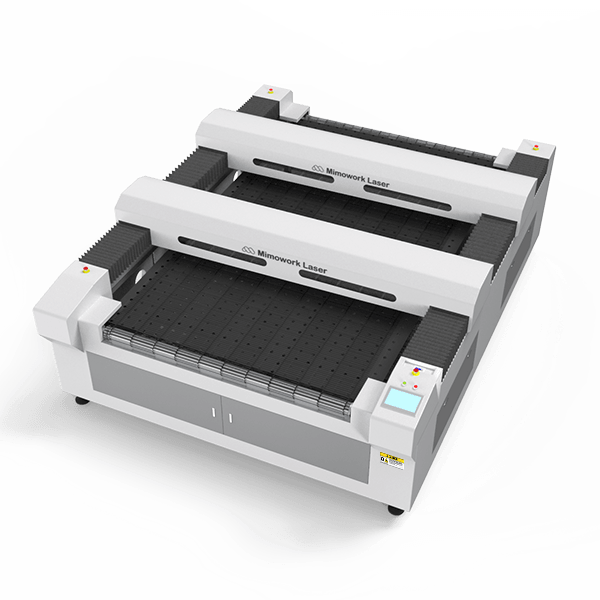

▶ Fabric laser cutting machine 160

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Servo Motor Upgrade Available

Mechanical Structure

Safe & Stable Structure

Customized Production

High-automation

R&D for Flexible Material Cutting

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further manual intervention.

Auto Feeding System

The Auto Feeder combined with the Conveyor Table is the ideal solution for series and mass production. It transports the flexible material (fabric most of the time) from the roll to the cutting process on the laser system. With stress-free material feeding, there is no material distortion while contactless cutting with laser ensures outstanding results.

Marker Pen Module

You can use the marker pen to make the marks on the cutting pieces, enabling the workers to sew easily. You can also use it to make special marks such as the serial number of the product, the size of the product, the manufacture date of the product, etc.

Ink-jet Print Module

It is widely used commercially for marking and coding products and packages. A high-pressure pump directs liquid ink from a reservoir through a gun body and a microscopic nozzle, creating a continuous stream of ink droplets via the Plateau-Rayleigh instability. Different inks are optional for specific fabrics.

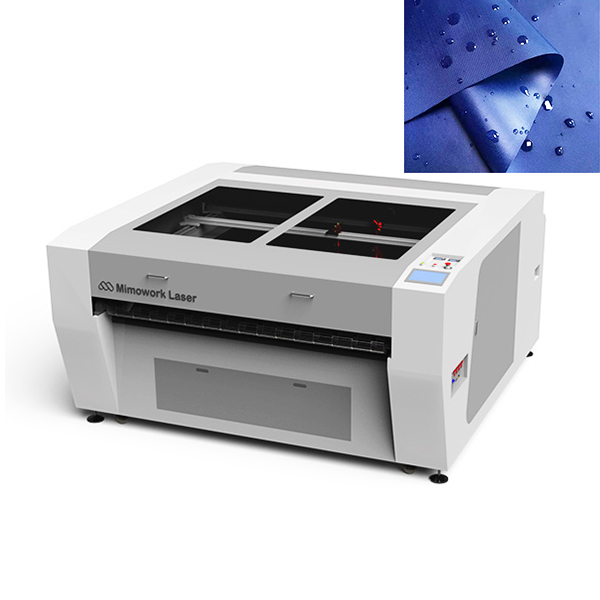

Samples of Laser Cutting Fabric

Video Display

Find more videos about our laser cutters at our Video Gallery

Denim Textiles Laser Cutting

◆ No pull deformation with contactless processing

◆ Crisp & clean edge without burr

◆ Flexible cutting for any shapes and sizes

Laser-friendly Fabrics:

denim, cotton, silk, nylon, kevlar, polyester, spandex fabric, faux fur, fleece, leather, lycra, mesh fabrics, suede, felt, non-woven fabric, plush, etc.

Laser Cutting Plaid Shirt, Blouse

Pictures Browse

What is the Best Laser for Cutting Fabric?

Both fiber and CO2 lasers can cut through fabric, but why do we barely see anyone use fiber lasers to cut fabric?

CO2 Laser:

The primary reason for using CO2 lasers for fabric cutting is that they are well-suited to materials that absorb the 10.6-micrometer wavelength of CO2 laser light.

This wavelength is effective for vaporizing or melting the fabric without causing excessive charring or burning.

CO2 lasers are often used for cutting natural fabrics like cotton, silk, and wool. They are also suitable for synthetic fabrics such as polyester and nylon.

Fiber Laser:

Fiber lasers are known for their high energy density and are often used for cutting metals and other materials that have high thermal conductivity. Fiber lasers operate at a wavelength of around 1.06 micrometers, which is less absorbed by fabric compared to CO2 lasers.

This means they may not be as efficient for cutting some types of fabric and may require higher power levels.

Fiber lasers can be used for cutting thin or delicate fabrics, but they may produce more heat-affected zones or charring compared to CO2 lasers.

In Conclusion:

CO2 lasers typically have a longer wavelength compared to fiber lasers, making them better for cutting thicker fabrics and materials with lower thermal conductivity. They are capable of producing high-quality cuts with smooth edges, which is essential for many textile applications.

If you primarily work with textiles and require clean, precise cuts on a variety of fabrics, a CO2 laser is generally the most suitable choice. CO2 lasers are better suited for fabrics due to their wavelength and ability to provide clean cuts with minimal charring. Fiber lasers can be used for fabric cutting in specific situations but are not as commonly employed for this purpose.

Related Fabric Cutter Laser

Laser Cutter for Cloth

• Laser Power: 100W / 150W / 300W

• Working Area (W *L): 1600mm * 1000mm

• Collecting Area (W *L): 1600mm * 500mm

Textile laser cutting machine (fabric)

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1800mm * 1000mm

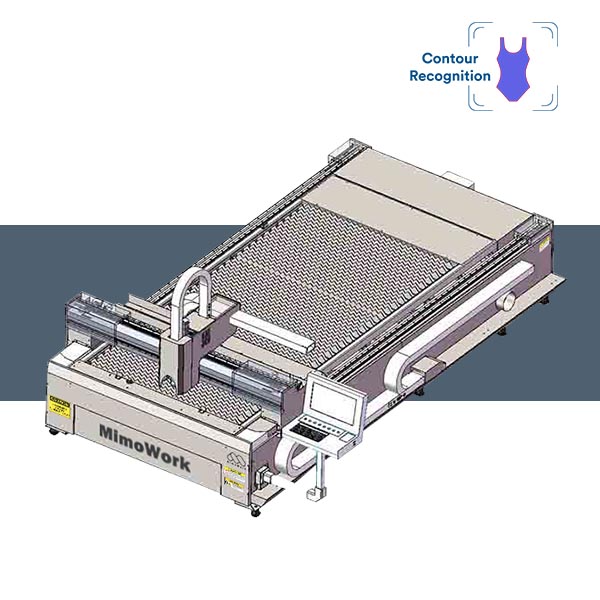

Industrial Laser Cutter for Fabric

• Laser Power: 150W/300W/500W

• Working Area (W *L): 1600mm * 3000mm

Related Articles

Laser Cut Vinyl – Catching On

Laser Cut Vinyl – A Few More Things

The Art of CO2 Laser Fabric Perforation

Learn more about fabric laser cutting machine price

Add yourself to the list!

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for China Wholesale Laser Cutter For Fabric Factories Quotes - Laser Fabric Cutter – MimoWork Laser , The product will supply to all over the world, such as: Iraq , Detroit , Austria , Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.