China Wholesale Laser Cutter Machine Factories Quotes - Small Laser Paper Cutter – MimoWork Laser

China Wholesale Laser Cutter Machine Factories Quotes - Small Laser Paper Cutter – MimoWork Laser Detail:

▶ laser paper cutter machine (both paper engraving and cutting)

Technical Data

|

Working Area (W *L) |

1000mm * 600mm (39.3” * 23.6 ”) 1300mm * 900mm(51.2” * 35.4 ”) 1600mm * 1000mm(62.9” * 39.3 ”) <Customized Table Sizes Available> |

|

Software |

Offline Software |

|

Laser Power |

40W/60W/80W/100W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

1750mm * 1350mm * 1270mm |

|

Weight |

385kg |

Structure Features

◼ Vacuum Table

The vacuum table can fix the paper on the honey comb table especially for some thin paper with wrinkles. Strong suction pressure from the vacuum table can guarantee the materials remain flat and stable to realize accurate cutting. For some corrugated paper like cardboard, you can put some magnets attached to the metal table to further fix materials.

◼ Air Assist

Air assist can blow the smoke and debris from the surface of the paper, bringing a relatively safe cutting finish without excessive burning. Also, the residue and accumulative smoke block out the laser beam through the paper, whose harm is especially obvious on cutting the thick paper, like cardboard, so proper air pressure need to be set to get rid of the smoke while not blowing them back to the paper surface.

▶ laser paper cutter machine (both laser paper engraving and cutting))

Upgrade Options for you to choose

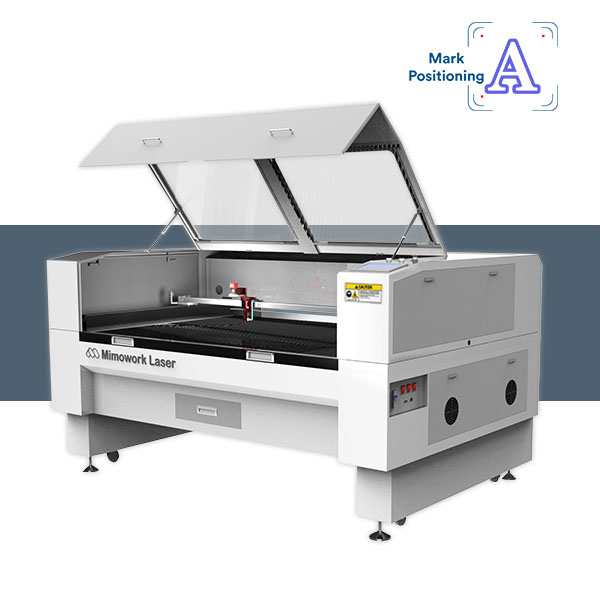

CCD Camera

For the printed paper like business card, poster, sticker and others, accurate cutting along the pattern contour is of significant importance. CCD Camera System offers contour cutting guidance by recognizing the feature area, which is easy to operate and eliminates unnecessary post-processing.

Servo Motors

Servo motors ensure higher speed and higher precision of the laser cutting and engraving. A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops.

Brushless DC Motors

Brushless DC (direct current) motor can run at a high RPM (revolutions per minute). The stator of the DC motor provides a rotating magnetic field that drives the armature to rotate. Among all the motors, the brushless dc motor can provide the most powerful kinetic energy and drive the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor and can reach a maximum engraving speed of 2000mm/s. You only need small power to engrave graphics on the paper, a brushless motor equipped with the laser engraver will shorten your engraving time with greater accuracy.

Customized A Laser Solution to Boost Your Paper Business

(laser cut invitation, laser cut crafts, laser cut cardboard)

What is Your Requirement?

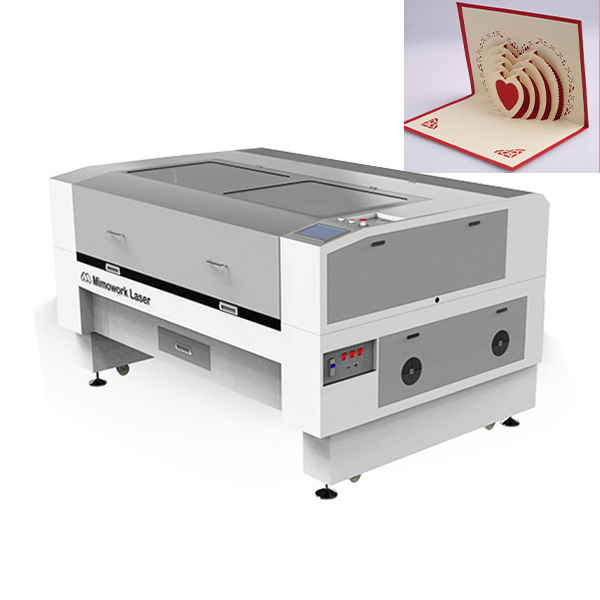

Samples of Laser Cutting & Engraving Paper

Video: Laser Cut Paper Design

>> More about Paper Laser Cutting

Special Applications for Paper Laser Cutting

Check out the videos >>

Fast Laser Engraving Invitation Card

Laser Cut Multi-layer Paper

What is Your Paper Idea?

Let the Paper Laser Cutter Help You!

Related Laser Paper Cutter Machine

Galvo Laser Marker 40

• High-speed laser engraving on paper

• Dynamic laser beam

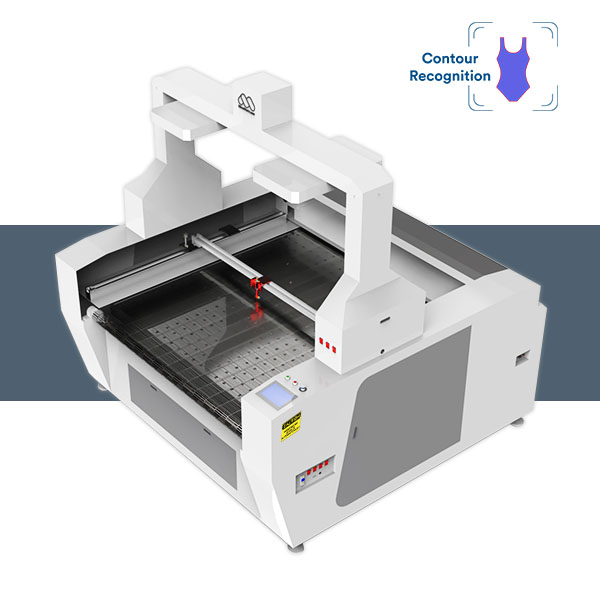

Contour Laser Cutter 90

• CCD camera laser cutter – Custom laser cutting paper

• Compact and small machine size

MimoWork Laser Provides!

Professional and affordable paper laser cutter

FAQ – Y’all Got Questions, We Got Answers

2. Is There a Paper Type Unsuitable for Laser Cutting?

Indeed, excessively thin paper, such as tissue paper, cannot be laser-cut. This paper is highly susceptible to burning or curling under the heat of a laser. Additionally, thermal paper is not advisable for laser cutting due to its propensity to change color when subjected to heat. In most cases, corrugated cardboard or cardstock is the preferred choice for laser cutting.

3. Can you Laser Engrave Cardstock?

Certainly, cardstock can be laser engraved. It’s crucial to carefully adjust the laser power to avoid burning through the material. Laser engraving on colored cardstock can yield high-contrast results, enhancing the visibility of the engraved areas.

Related Articles

Revolutionizing Laser Cutting: Galvo – Multi-Layer of Paper

Cricut VS Laser: Which One Suits You?

Laser-Cut Felt Coasters: Where Precision Meets Artistry

How to laser cut paper at home, how to make layered paper cut art

Click here to learn paper laser cutter!

Product detail pictures:

Related Product Guide:

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of China Wholesale Laser Cutter Machine Factories Quotes - Small Laser Paper Cutter – MimoWork Laser , The product will supply to all over the world, such as: Jersey , California , Argentina , We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.