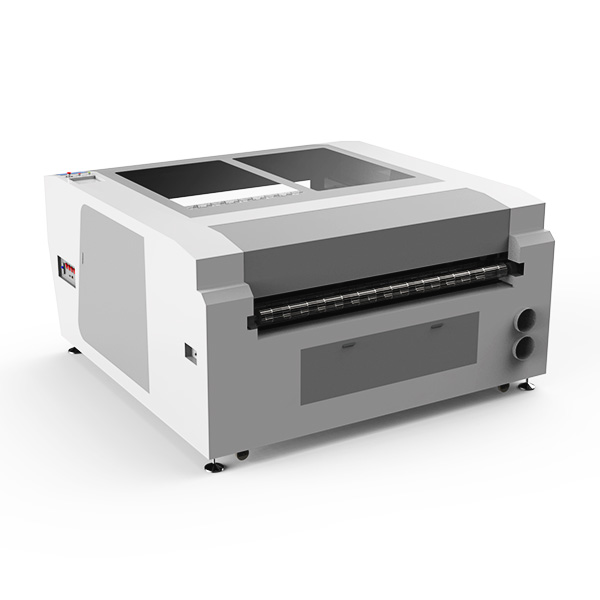

China Wholesale Laser Cutting Bag Factories Pricelist - Contour Laser Cutter 160 – MimoWork Laser

China Wholesale Laser Cutting Bag Factories Pricelist - Contour Laser Cutter 160 – MimoWork Laser Detail:

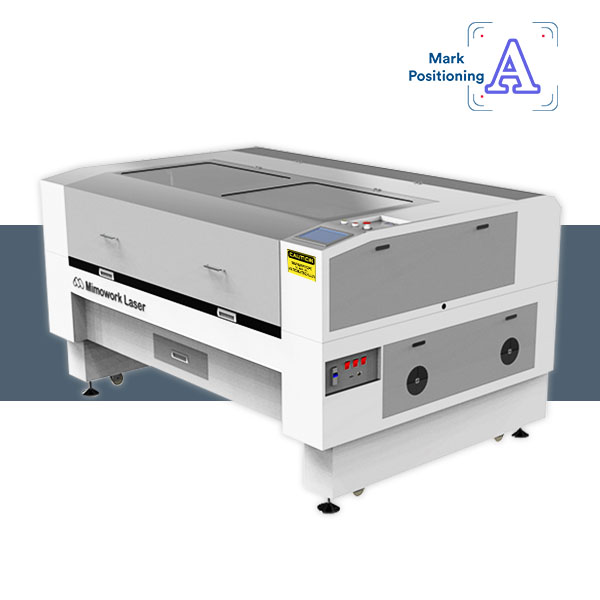

Advantages of Contour Laser Cutter 160

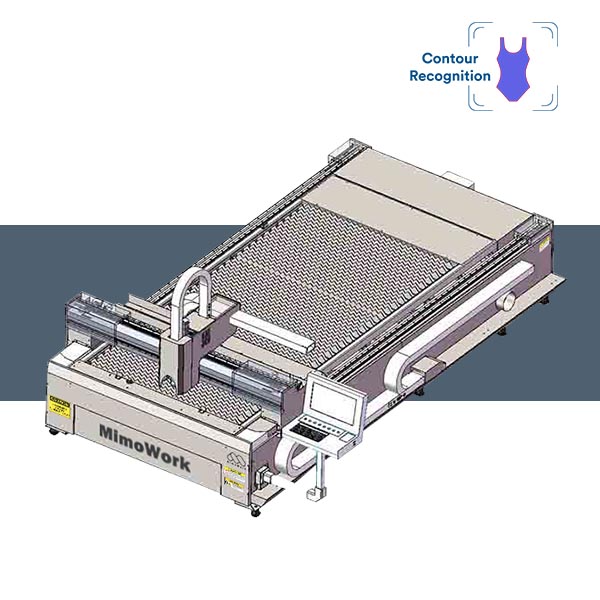

Larger format, Wider applications

R&D for flexible materials like sublimation fabric and garment accessories

Enhanced two laser heads, greatly increase your productivity (optional)

CNC (Computer Numerical Control) and computer data support high automation processing and constant stable high-quality output

MimoWork Smart Vision System automatically corrects deformation and deviation

Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional)

Technical Data

| Working Area (W *L) | 1600mm * 1,000mm (62.9’’ * 39.3’’) |

| Software | CCD Registration Software |

| Laser Power | 100W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Servo Motor Drive & Belt Control |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Enhance the laser ability of your machine

Conveyor Working Table

Stainless steel web will be suitable for flexible materials like direct injection and digitally printed fabrics. With the Conveyor Table, continuously process can be easily realized, greatly increasing your productivity.

Feature Marks Location

The CCD Camera equipped next to the laser head can detect feature marks to location the printed patterns and the software will apply the cutting file to the actual pattern in 0.001mm accuracy to ensure the highest precious cutting result.

Optional Servo Motor

Servo motor motion system can be selected to provide a higher cutting speed. Servo motor will improve the stable performance of C160 when cutting complex outer contour graphics.

Video Demonstration of Laser Cutting Foil Material

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Print Acrylic

Polished edge and accurate contour cutting

Common materials and applications

of Contour Laser Cutter 160

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Product detail pictures:

Related Product Guide:

We always get the job done to be a tangible staff to ensure that we can easily offer you the best high-quality and the greatest value for China Wholesale Laser Cutting Bag Factories Pricelist - Contour Laser Cutter 160 – MimoWork Laser , The product will supply to all over the world, such as: Poland , Rome , Malta , We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!