China Wholesale Laser Cutting Of Fabric Manufacturers Suppliers - 80W CO2 Laser Engraver – MimoWork Laser

China Wholesale Laser Cutting Of Fabric Manufacturers Suppliers - 80W CO2 Laser Engraver – MimoWork Laser Detail:

80W CO2 Laser Engraver – The Best without Breaking the Bank

Technical Data

|

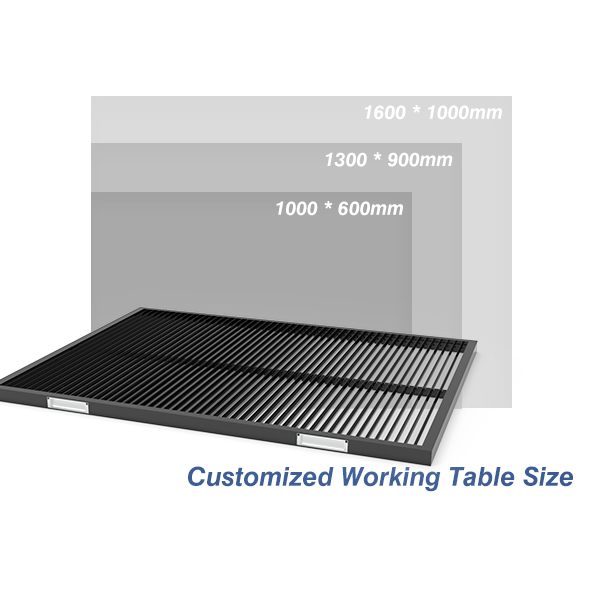

Working Area (W *L) |

1000mm * 600mm (39.3” * 23.6 ”) 1300mm * 900mm(51.2” * 35.4 ”) 1600mm * 1000mm(62.9” * 39.3 ”) <Customized Table Sizes Available> |

|

Software |

Offline Software |

|

Laser Power |

80W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

1750mm * 1350mm * 1270mm |

|

Weight |

385kg |

Brushless DC Motors Upgrade Option

Increasing the Engraving Speed to the Max

Brushless DC (direct current) motor can run at a high RPM (revolutions per minute). The stator of the DC motor provides a rotating magnetic field that drives the armature to rotate. Among all the motors, the brushless dc motor can provide the most powerful kinetic energy and drive the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor and can reach a maximum engraving speed of 2000mm/s. The brushless dc motor is rarely seen in a CO2 laser cutting machine. This is because the speed of cutting through a material is limited by the thickness of the materials. On the contrary, you only need small power to carve graphics on your materials, A brushless motor equipped with the laser engraver will shorten your engraving time with greater accuracy.

Looking for Other Upgrades?

CCD Camera

CCD Camera can recognize and locate the printed pattern on the materials to assist the laser with accurate cutting. Signage, plaques, artwork and wood photo, branding logos, and even memorable gifts made of printed wood, printed acrylic and other printed materials can be easily processed.

Rotary Device

If you want to engrave on the cylindrical items, the rotary attachment can meet your needs and achieve a flexible and uniform dimensional effect with a more precise carved depth. Plugin the wire into the right places, the general Y-axis movement turns into the rotary direction, which solves the unevenness of engraved traces with the changeable distance from the laser spot to the round material’s surface on the plane.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

>> More details about motors

Want Tailored Specifications of your 80W CO2 Laser Engraver?

We are ready to help

Video Display

▷ How to Cut & Engrave Wood?

▷ How to Cut & Engrave Acrylic?

Compatible Materials Suitable for Laser Processing:

Complete List of Materials Overview

Please note that your case might differ, consult with our specialist first.

Related News & Articles

Can a laser engraver cut wood?

Choosing the Best Wood for Laser Wood Carving: A Guide for Woodworkers

Types of Acrylic Suitable for Laser Cutting & Laser Engraving

We don’t settle for mediocre resultsNeither should you

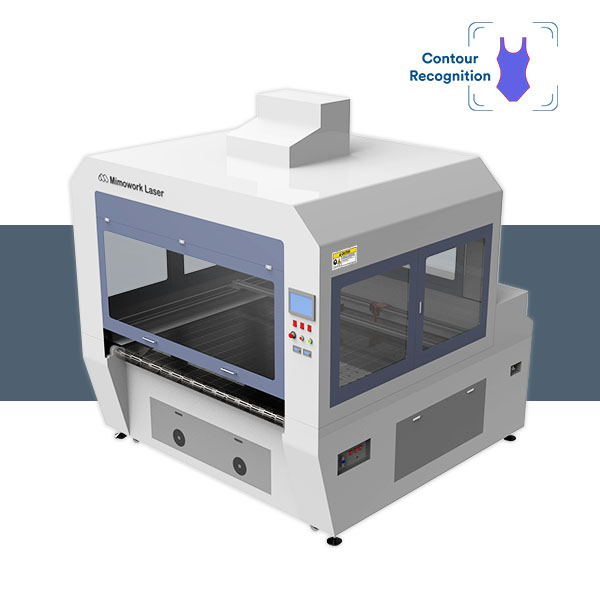

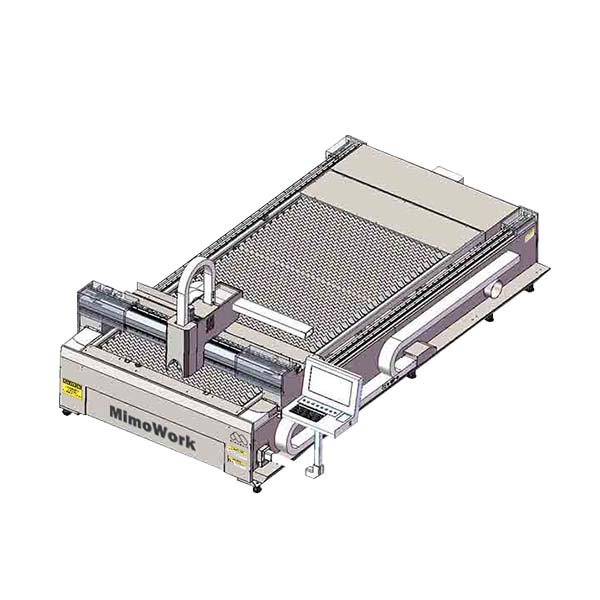

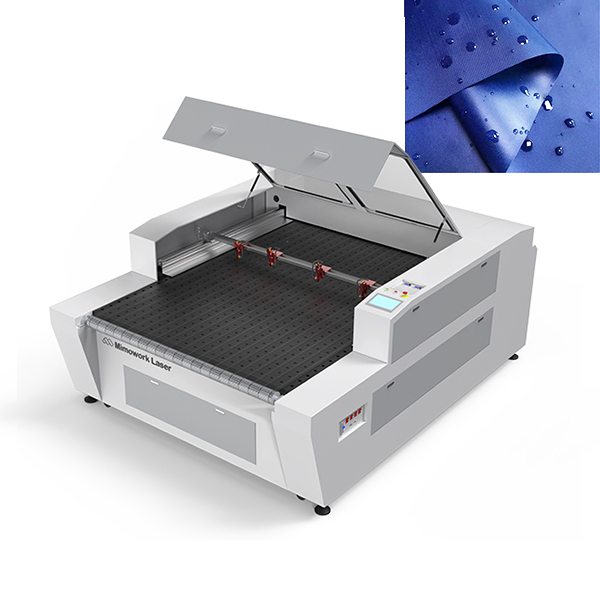

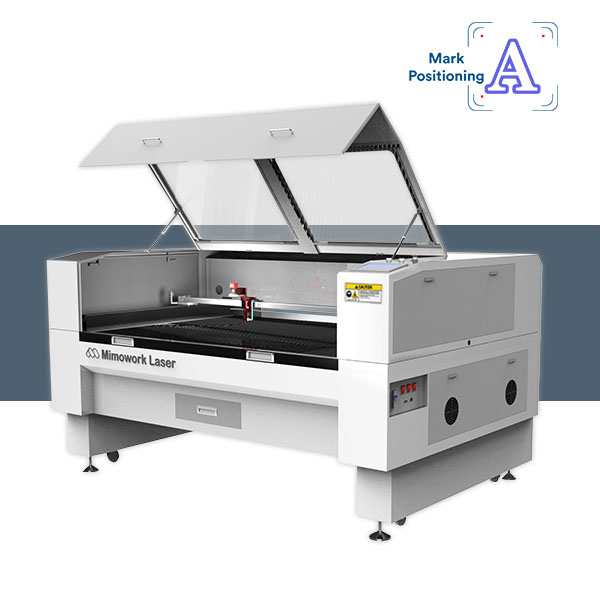

Product detail pictures:

Related Product Guide:

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for China Wholesale Laser Cutting Of Fabric Manufacturers Suppliers - 80W CO2 Laser Engraver – MimoWork Laser , The product will supply to all over the world, such as: Albania , Albania , Manila , We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.