China Wholesale Laser Cutting Sublimation Fabric Factories Quotes - 1390 CO2 Laser Cutting Machine – MimoWork Laser

China Wholesale Laser Cutting Sublimation Fabric Factories Quotes - 1390 CO2 Laser Cutting Machine – MimoWork Laser Detail:

Great for Laser Engraving of Wood, Leather & Acrylic

Technical Data

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* More sizes of laser working table are customized

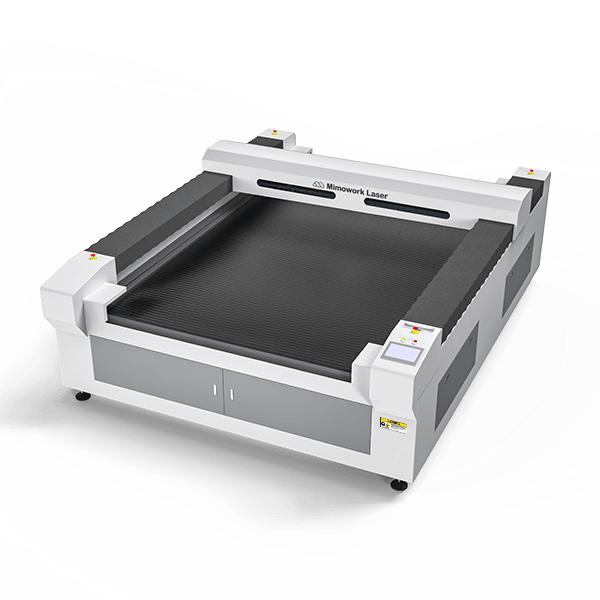

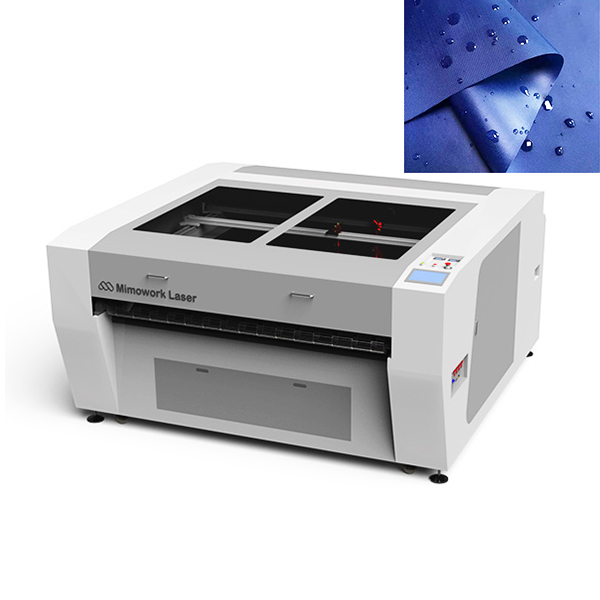

(1390 CO2 Laser Cutting Machine)

One Machine, Multiple Functions

Ball & Screw

The ball screw is a powerful linear actuator that minimizes friction and precisely translates rotational motion into linear motion. Ideal for high-thrust loads, these screws are crafted to tight tolerances for ultra-precision in high-precision situations. The ball assembly acts as the nut, while the threaded shaft acts as the screw, and the recirculating ball mechanism adds extra bulk. When used in laser cutting, ball screws ensure high-speed and high-precision results.

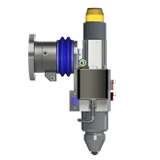

Mixed Laser Head

The metal non-metallic laser cutting head, also known as a mixed laser head, is an essential component of a combined laser cutting machine. With this laser head, you can easily cut both metal and non-metal materials. Its Z-Axis transmission part tracks the focus position, while the double drawer structure enables the use of two different focus lenses for materials of different thicknesses without the need for focus distance or beam alignment adjustment. This feature improves cutting flexibility and makes operation easy, while different assist gas can be used for various cutting jobs.

Servo Motors

A servomotor is a sophisticated mechanism that utilizes position feedback to control motion and the final position. It receives an input signal, analog or digital, indicating the desired output shaft position. Equipped with a position encoder, it provides feedback on position and speed. When the output position deviates from the command position, an error signal is generated, and the motor rotates as needed to correct the position. Servo motors enhance the speed and precision of laser cutting and engraving.

Auto Focus

Auto Focus technology is a game-changer in the field of laser cutting, especially when working with metal materials. This advanced feature allows for a certain focus distance to be set in the software when the material being cut is not flat or has varying thickness. The laser head will then automatically adjust its height and focus distance, ensuring a consistently high cutting quality. By eliminating the need for manual adjustments, Auto Focus technology saves time and increases efficiency, while also improving the accuracy and precision of the cuts. This feature is a must-have for any serious laser cutting and engraving operation looking to achieve optimal results.

Want to Learn More about our Upgradable Options for the 1390 CO2 Laser Cutting Machine?

▶ FYI: The 1390 CO2 Laser Cutting Machine is suitable to cut and engrave on solid materials such as acrylic and wood. Honeycomb working table and knife strip cutting table can carry the materials and help to reach best the cutting effect without dust and fume that can be sucked into and purified.

<a href="https://www.mimowork.com/working-table/" title=">> Discover laser cutting tables” target=”_blank”>

>> Discover laser cutting tables

<a href="https://www.mimowork.com/fume-extractor/" title=">> Discover laser fume extractor” target=”_blank”>

>> Discover laser fume extractor

Beauty of Modern Engineering

Design Highlights

Two-way Penetration Design

Achieving laser engraving on large-format materials is now made easy with the two-way penetration design of our machine. The material board can be placed through the whole width of the machine, extending even beyond the table area. This design allows for flexibility and efficiency in your production, whether it be cutting or engraving. Experience the convenience and precision of our large-format wood laser engraving machine.

Stable and Safe Structure

Ensures SAFE Operations

◾ Signal Light

The signal light on the laser machine serves as a visual indicator of the machine’s status and its functions. It provides real-time information to assist in making informed judgments and operating the machine correctly.

◾ Emergency Button

In the event of a sudden and unexpected condition, the emergency button ensures your safety by immediately stopping the machine.

◾ Safe Circuit

To ensure safe production, it’s essential to have a circuit that functions well. Smooth operation depends on a properly functioning circuit that meets safety standards.

◾ CE Certification

Owning the legal right of marketing and distributing, MimoWork Laser Machine has been proud of the solid and reliable quality.

◾ Adjustable Air Assist

Air assist is an essential feature that helps prevent wood burn and removes debris from the surface of engraved wood. It works by delivering compressed air from an air pump into the carved lines through a nozzle, clearing the extra heat gathered on the depth. By adjusting the pressure and size of airflow, you can achieve the burning and darkness vision that you desire. If you have any questions about how to optimize the air assist feature for your project, our team is here to help.

Video of Laser Cutting & Engraving Wood

We offered some great tips and things that you need to be considered when working with wood. Wood is wonderful when being processed with a CO2 Laser Machine. People have been quitting their full-time job to start a Woodworking business because of how profitable it is!

Common materials and applications

of Flatbed Laser Cutter 130

Materials: Acrylic, Wood, Paper, Plastic, Glass, MDF, Plywood, Laminates, Leather, and other Non-metal Materials

Applications: Signs(signage), Crafts, Jewelry, Key chains, Arts, Awards, Trophies, Gifts, etc.

View more materials

View more applications

Join our Growing List of Satisfied Clients

With Our Customizable Flatbed Laser Cutter

Product detail pictures:

Related Product Guide:

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for China Wholesale Laser Cutting Sublimation Fabric Factories Quotes - 1390 CO2 Laser Cutting Machine – MimoWork Laser , The product will supply to all over the world, such as: Angola , Borussia Dortmund , Cannes , Make the women more attractive is our sales philosophy. Being customers' trusted and preferred brand supplier is the goal of our company. We've been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!