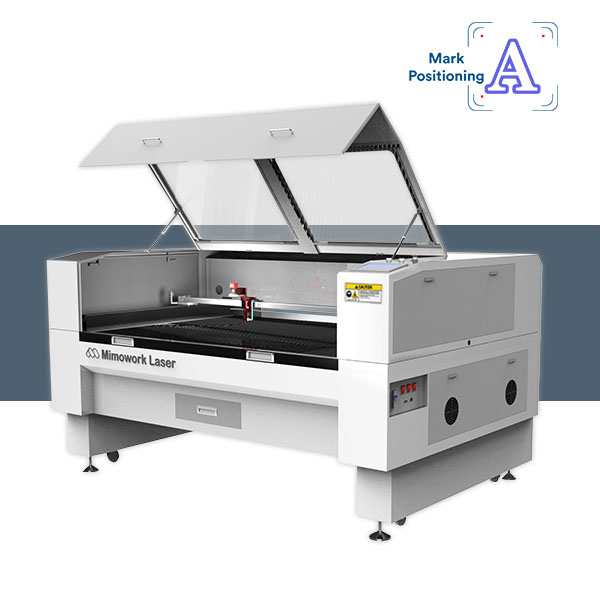

China Wholesale Laser Cutting Sublimation Fabric Factories Quotes - Flatbed Laser Cutter 130L – MimoWork Laser

China Wholesale Laser Cutting Sublimation Fabric Factories Quotes - Flatbed Laser Cutter 130L – MimoWork Laser Detail:

Advantages of Flatbed Laser Cutter

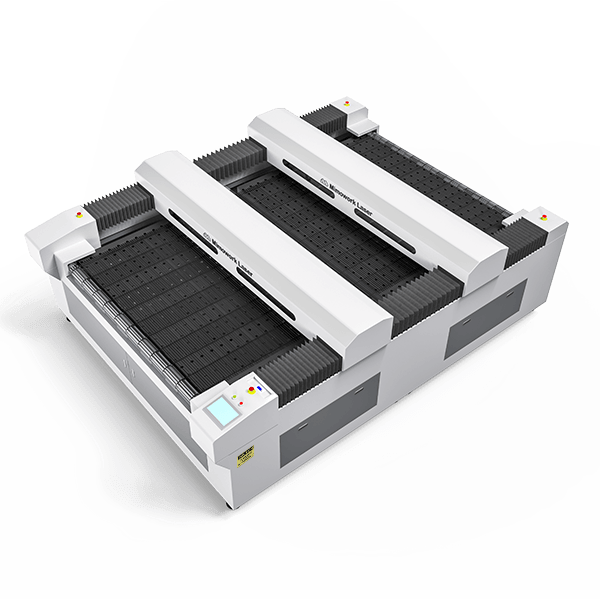

A Giant Leap in Productivity

Technical Data

| Working Area (W * L) | 1300mm * 2500mm (51” * 98.4”) |

| Software | Offline Software |

| Laser Power | 150W/300W |

| Laser Source | CO2 Glass Laser Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Knife Strip Working Table |

| Max Speed | 1~300mm/s |

| Acceleration Speed | 1000~3000mm/s2 |

R&D for Processing Acrylic And Wood

Belt Drive

A belt is a looped strip of flexible material used to mechanically link two or more rotating shafts. A belt drive offers smooth transmission of power between shafts at a considerable distance. Belt drives are used as the source of motion to transfer to efficiently transmit power or to track relative movement. In the motion of belt drive, power transmission results make one side of the pulley more tightened compared to the other side. In horizontal drives, the tightened side is always kept on the lower side of two pulleys because the sag of the upper side slightly increases the angle of the folding of the belt on the two pulleys. Belt drives are simple and economical.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

Fields of Application

Laser Cutting for Your Industry

Advertising & Gifts

A clear and smooth edge without chipping

Digital Printing

Clean and smooth edge with thermal treatment

Common materials and applications

of Flatbed Laser Cutter 130L

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for China Wholesale Laser Cutting Sublimation Fabric Factories Quotes - Flatbed Laser Cutter 130L – MimoWork Laser , The product will supply to all over the world, such as: Sri Lanka , Riyadh , Guinea , Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

A good manufacturers, we have cooperated twice, good quality and good service attitude.