China Wholesale Laser Cutting Uniform Quotes Pricelist - Laser Wire Stripper – MimoWork Laser

China Wholesale Laser Cutting Uniform Quotes Pricelist - Laser Wire Stripper – MimoWork Laser Detail:

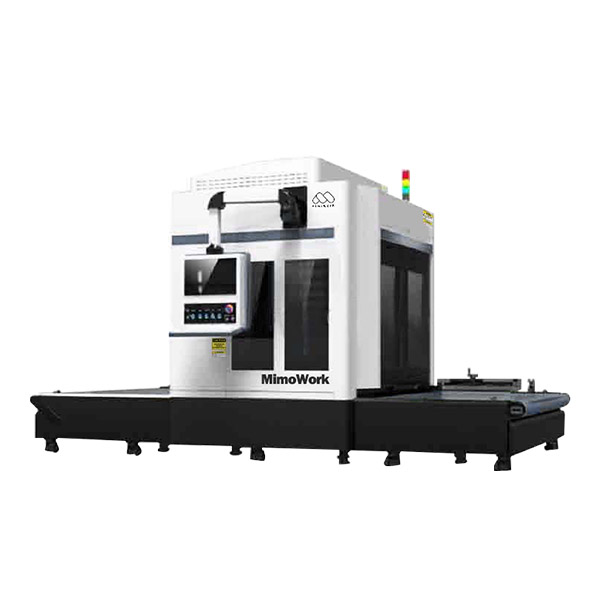

Mechanical Support from Laser Wire Stripper

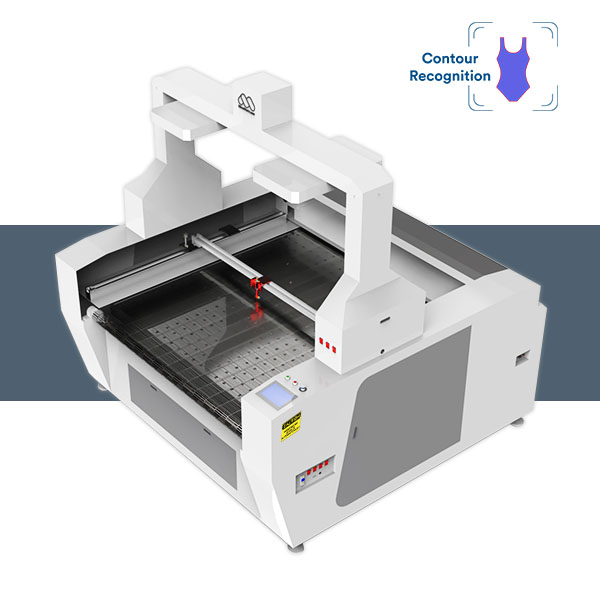

◼ Small Size

The desktop model with compact and small in size.

◼ Automation Working Flow

One-key operation with the automatic computer-control system, saving time and labor.

◼ High-Speed Stripping

Stripping wire simultaneously by up and down dual laser heads brings high efficiency and convenience for stripping.

Technical Data

| Working Area (W * L) | 200mm * 50mm |

| Laser Power | US Synrad 30W RF Metal Laser Tube |

| Cutting Speed | 0-6000mm/s |

| Positioning Precision | within 0.02mm |

| Repeat Precision | within 0.02mm |

| Dimension | 600 * 900 * 700mm |

| Cooling Method | air cooling |

Why choose laser to strip wires?

Principle of laser wire stripping

During the laser wire stripping process, the energy of radiation emitted by the laser is absorbed strongly by the insulating material. As the laser penetrates the insulation, it vaporizes the material through to the conductor. However, the conductor strongly reflects the radiation at the CO2 laser wavelength and is therefore unaffected by the laser beam. Because the metallic conductor is essentially a mirror at the wavelength of the laser, the process is effective “self-terminating”, that is the laser vaporizes all of the insulating material down to the conductor and then stops, so no process control is required to prevent damage to the conductor.

Advantages from laser wire stripping

✔ Clean and thorough stripping for insulation

✔ No damage to the core conductor

Comparatively, conventional wire-stripping tools make physical contact with the conductor, which can damage the wire and slow down processing speed.

✔ High repetition – steady quality

Video Glance of laser wire stripping

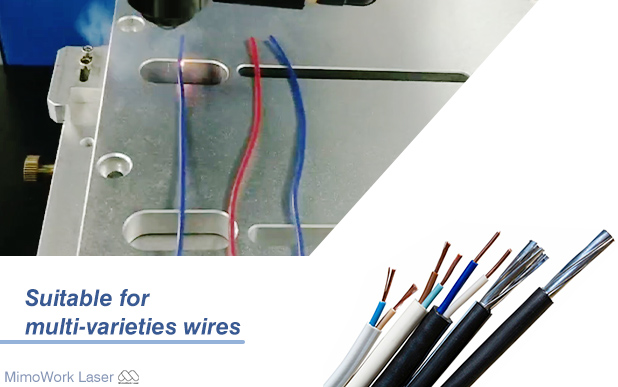

Suitable materials

Fluoropolymers (PTFE, ETFE, PFA), PTFE /Teflon®, Silicone, PVC, Kapton®, Mylar®, Kynar®, Fiberglass, ML, Nylon, Polyurethane, Formvar®, Polyester, Polyesterimide, Epoxy, Enameled coatings, DVDF, ETFE /Tefzel®, Milene, Polyethylene, Polyimide, PVDF and other hard, soft or high-temperature material…

Fields of Application

Common applications

(medical electronics, aerospace, consumer electronics and automotive)

Learn more about laser wire stripper price, operation guide

Add yourself to the list!

Product detail pictures:

Related Product Guide:

We enjoy a very good reputation among our customers for our excellent product quality, competitive price and the best service for China Wholesale Laser Cutting Uniform Quotes Pricelist - Laser Wire Stripper – MimoWork Laser , The product will supply to all over the world, such as: Egypt , Portugal , Seattle , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!