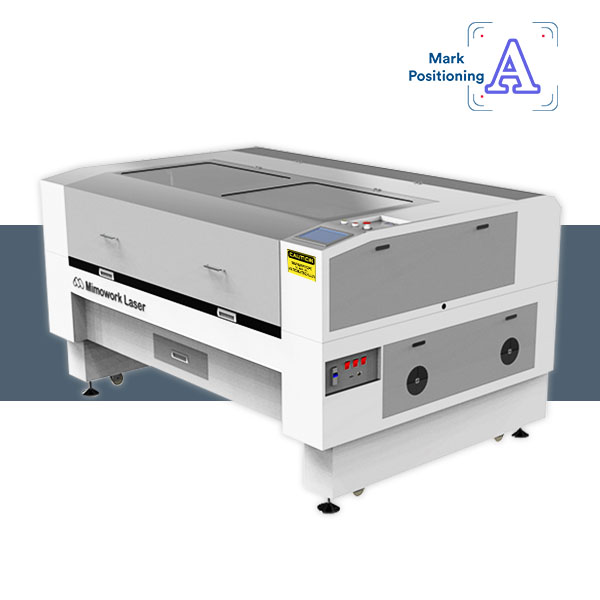

China Wholesale Leather Laser Cutter Manufacturers Suppliers - 1325 CO2 Laser Cutting Machine – MimoWork Laser

China Wholesale Leather Laser Cutter Manufacturers Suppliers - 1325 CO2 Laser Cutting Machine – MimoWork Laser Detail:

Advantages of 1325 CO2 Laser Cutting Machine

Revolutionizing Productivity with a Quantum Leap

◉ Sturdy construction: The machine has a reinforced bed made from 100mm square tubes and undergoes vibration aging and natural aging treatment for durability

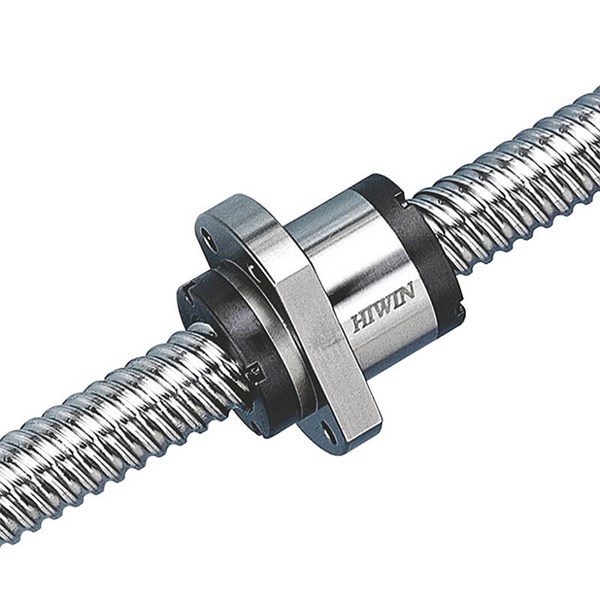

◉ Precise transmission system: The machine’s transmission system consists of an X-axis precision screw module, a Y-axis unilateral ball screw, and a servo motor drive for accurate and reliable operation.

◉ Constant Optical Path Design: The machine features a constant optical path design with five mirrors, including third and fourth mirrors that move with the laser head to maintain the optimal output optical path length.

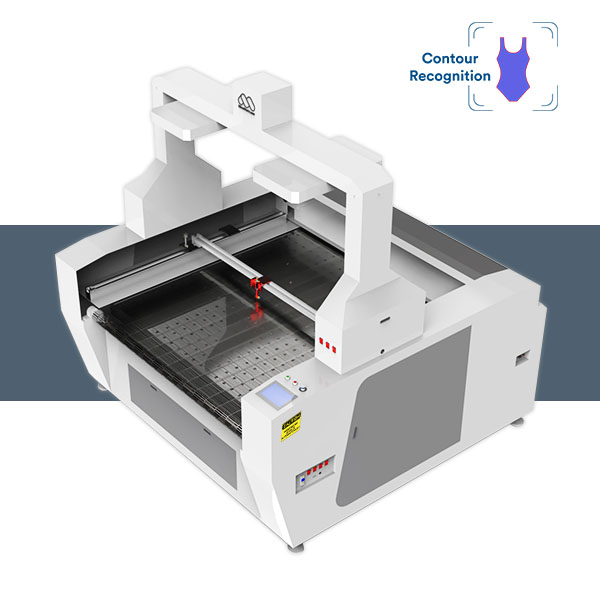

◉ CCD camera system: The machine is equipped with a CCD camera system that enables edge finding and expands the range of applications

◉ High production speed: The machine has a maximum cutting speed of 36,000mm/min and a maximum engraving speed of 60,000mm/min, allowing for faster production.

Details of 1325 CO2 Laser Cutting Machine

Technical Data

| Working Area (W * L) | 1300mm * 2500mm (51” * 98.4”) |

| Software | Offline Software |

| Laser Power | 150W/300W/500W |

| Laser Source | CO2 Glass Laser Tube |

| Mechanical Control System | Ball Screw & Servo Motor Drive |

| Working Table | Knife Blade or Honeycomb Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~3000mm/s2 |

| Position Accuracy | ≤±0.05mm |

| Machine Size | 3800 * 1960 * 1210mm |

| Operating Voltage | AC110-220V±10%,50-60HZ |

| Cooling Mode | Water Cooling and Protection System |

| Working Environment | Temperature:0—45℃ Humidity:5%—95% |

(Upgrades for your 1325 CO2 Laser Cutting Machine)

R&D for Processing Non-metal (Wood & Acrylic)

Servo Motors

A servo motor is a highly advanced closed-loop servomechanism that uses position feedback to control its motion and final position accurately. The control input to this motor can be an analog or digital signal, which represents the commanded position for the output shaft. The servo motor is equipped with a position encoder that provides speed and position feedback to the system. In the simplest configuration, only the position is measured. During operation, the measured position of the output is compared to the command position, which is the external input to the controller. If the output position differs from the required position, an error signal is generated, which causes the motor to rotate in the direction needed to bring the output shaft to the appropriate position. As the positions approach each other, the error signal reduces to zero, and the motor comes to a stop. The use of servomotors in laser cutting and engraving ensures high-speed and high-precision operation. This technology plays a critical role in ensuring that the laser cutting and engraving processes are carried out with exceptional accuracy and consistency, resulting in high-quality end products.

Auto Focus

The Autofocus feature is a valuable tool that is specifically designed for metal cutting. When working with non-flat or unevenly thick materials, it is necessary to set a specific focus distance within the software to achieve optimal cutting results. The auto-focus function enables the laser head to adjust its height and focus distance automatically, ensuring that it remains consistent with the settings specified in the software. This feature is essential for achieving high cutting quality and precision, regardless of the material thickness or shape.

Ball Screw Module

The Ball Screw is a highly efficient method of converting rotary motion into linear motion, using a recirculating ball mechanism between the screw shaft and the nut. Unlike a traditional sliding screw, the ball screw requires significantly less driving torque, making it an ideal choice for reducing the amount of drive motor power required. This feature is particularly important in applications where energy consumption must be minimized. By incorporating the Ball Screw Module into the design of the MimoWork Flatbed Laser Cutter, the machine is capable of providing exceptional improvements in efficiency, precision, and accuracy. The use of the ball screw technology ensures that the laser cutter can operate with higher levels of speed and accuracy, making it an ideal choice for a wide range of applications. The improved efficiency provided by the Ball Screw Module allows for faster processing times, resulting in increased productivity and throughput. Additionally, the higher precision and accuracy of the ball screw technology ensures that the laser cutter can produce high-quality end products that meet the most demanding standards. Overall, the incorporation of the Ball Screw Module into the MimoWork Flatbed Laser Cutter provides users with a highly advanced and efficient machine that can handle a wide range of cutting and engraving tasks with exceptional precision and accuracy.

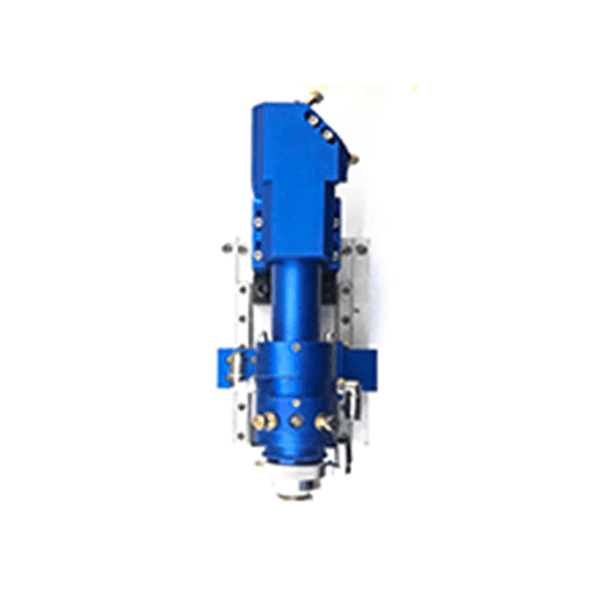

Mixed Laser Head

The metal & non-metal combined laser cutting machine includes a mixed laser head, also known as a metal non-metallic laser cutting head. This component is essential for cutting both metal and non-metal materials. The laser head features a Z-Axis transmission part that moves up and down to track the focus position. The double drawer structure of the laser head allows for two different focus lenses to be used without needing to adjust the focus distance or beam alignment. This design provides greater cutting flexibility and simplifies the operation. Additionally, the machine allows for different assist gases to be used for different cutting jobs.

Video Demonstration of Thick Acrylic Laser Cutting

Extra Thick, Extra Wide

<a href="https://www.mimowork.com/video-gallery/" title="Source from: Video Gallery” target=”_blank”>

Source from: Video Gallery

<a href="https://www.mimowork.com/acrylic-laser-cutter-engraver/" title="/Learn more about Acrylic Laser Cutting/” target=”_blank”>

/Learn more about Acrylic Laser Cutting/

Fields of Application

Laser Cutting for Your Industry

Laser Cutting on Advertising

A clear and smooth edge without chipping

✔ Burr-free cutting: Laser cutting machines utilize a powerful laser beam to cut through a variety of materials with ease. This results in a clean, burr-free cutting edge that requires no additional processing or finishing.

✔ No shavings: Unlike traditional cutting methods, laser cutting machines produce no shavings or debris. This makes cleaning up after processing quick and easy.

✔ Flexibility: With no limitations on shape, size, or pattern, laser cutting, and engraving machines allow for flexible customization of a wide range of materials.

✔ Single processing: Laser cutting and engraving machines are capable of performing both cutting and engraving in a single process. This not only saves time but also ensures that the end product meets the most exacting standards.

Metal Cutting & Engraving

High speed & high quality with force-free and top precision

✔ Stress-free and contactless cutting avoid metal fracture and breakage with proper power

✔ Multi-axis flexible cutting and engraving in multi-direction results to diverse shapes and complex patterns

✔ Smooth and burr-free surface and edge eliminate secondary finishing, meaning short workflow with quick response

Common materials and applications

of 1325 CO2 Laser Cutting Machine

Materials: Acrylic, Wood, MDF, Plywood, Plastic, Laminates, Polycarbonate, and other Non-metal Material

Applications: Signs, Crafts, Ads Displays, Arts, Awards, Trophies, Gifts and many others

View more materials

View more applications

This Laser Cutter we Created is a Giant Leap in Productivity

Your Needs Are what we Can Fulfill

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for China Wholesale Leather Laser Cutter Manufacturers Suppliers - 1325 CO2 Laser Cutting Machine – MimoWork Laser , The product will supply to all over the world, such as: British , Argentina , Melbourne , Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.