China Wholesale Template Laser Cutting Machine Quotes Pricelist - CO2 Laser Engraving Machine for Glass – MimoWork Laser

China Wholesale Template Laser Cutting Machine Quotes Pricelist - CO2 Laser Engraving Machine for Glass – MimoWork Laser Detail:

▶ Laser glass etcher machine (crystal glass engraving)

Technical Data

|

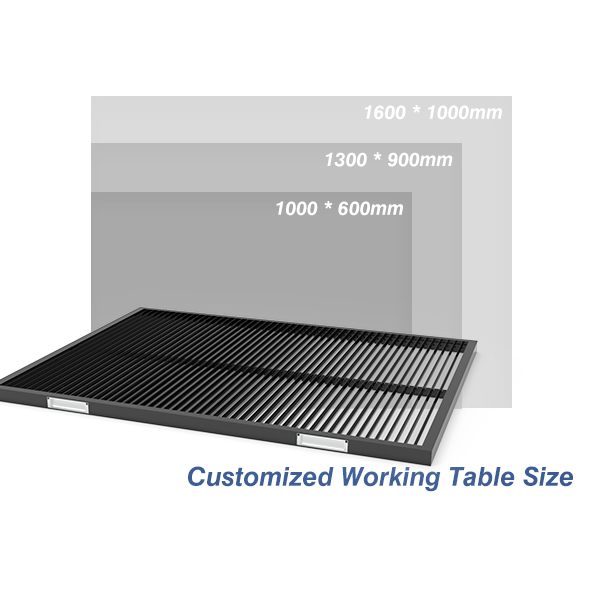

Working Area (W *L) |

1000mm * 600mm (39.3” * 23.6 ”) 1300mm * 900mm(51.2” * 35.4 ”) 1600mm * 1000mm(62.9” * 39.3 ”) <Customized Table Sizes Available> |

|

Software |

Offline Software |

|

Laser Power |

50W/65W/80W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

1750mm * 1350mm * 1270mm |

|

Weight |

385kg |

Upgrade options when laser glass etching

Rotary Device

Designed for glass bottle laser engraver, wine glass etching machine, the rotary device provides great convenience and flexibility in engraving cylindrical and conical glassware. Import the graphic file and set up the parameters, the glassware will automatically rotate and turn to make ensure the accurate laser engraving on the right position, meet your needs for a uniform dimensional effect with a more precise carved depth. With the rotary attachment, you can realize the delicate visual effect of engraving on the beer bottle, wine glasses, champagne flutes.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of laser cutting and engraving.

Brushless DC Motors

Brushless DC (direct current) motor can run at a high RPM (revolutions per minute). The stator of the DC motor provides a rotating magnetic field that drives the armature to rotate. Among all the motors, the brushless dc motor can provide the most powerful kinetic energy and drive the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor and can reach a maximum engraving speed of 2000mm/s. The brushless dc motor is rarely seen in a CO2 laser cutting machine. This is because the speed of cutting through a material is limited by the thickness of the materials. On the contrary, you only need small power to carve graphics on your materials, A brushless motor equipped with the laser engraver will shorten your engraving time with greater accuracy.

<a href="https://www.mimowork.com/laser/key-facts-you-need-to-konw-about-co2-laser-machine" title=">> More details about motors” target=”_blank”>

>> More details about motors

Customized laser solutions to boost your business

Tell us your requirements

Why choose glass laser engraving

◼ No breakage and crack

Contactless processing means no stress on the glass, which greatly stops glassware from breakage and cracking.

◼ High repetition

Digital control system and automatic engraving ensure high quality and high repetition.

◼ Fine engraved details

Fine laser beam and precise engraving as well as the rotary device, help with intricate pattern engraving on the glass surface, like logo, letter, photo.

(custom laser etched glass)

Samples of laser engraving

<a href="https://www.mimowork.com/laser-cutting-glass/" title=">> learn more glass laser engraving” target=”_blank”>

>> learn more glass laser engraving

• Wine Glasses

• Champagne Flutes

• Beer Glasses

• Trophies

• Decoration LED Screen

Related Glass Laser Engraver

UV Galvo Laser Marking Machine

• Cold processing with few heat affected zone

• Suitable for precise laser marking

MimoWork Laser can meet you !

Customized Glass Engraving Laser Solutions

Related links:

<a href="https://www.mimowork.com/laser-engraving/" title=">> laser engraving” target=”_blank”>

>> laser engraving

<a href="https://www.mimowork.com/service/" title=">> laser service” target=”_blank”>

>> laser service

How to laser engrave glass, laser photo on glass

Click here to learn more!

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for China Wholesale Template Laser Cutting Machine Quotes Pricelist - CO2 Laser Engraving Machine for Glass – MimoWork Laser , The product will supply to all over the world, such as: Jamaica , Adelaide , Malta , All these products are manufactured in our factory located in China. So we can guarantee our quality seriously and availably. Within these four years we sell not only our products but also our service to clients throughout the world.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!