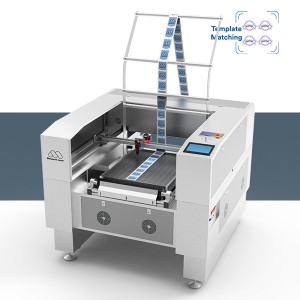

CCD Laser Cutter – Automatic Pattern Recognition

Optical Recognition System

Strong & Flexible Machine Structure

◾ Enclosed Design

The enclosed design provides a safe and clean work environment without fumes and odor leaks. You can look through the acrylic window to check the CCD laser cutting and monitor the real-time condition inside.

◾ Pass-Through Design

The pass-through design makes cutting ultra-long materials possible.

For example, if your acrylic sheet is longer than the working area, but your cutting pattern is within the working area, then you do not need to replace a larger laser machine, the CCD laser cutter with a pass-through structure can help you with your production.

◾ Air Blower

Air assistance is significant for you to ensure smooth production. We put the air assist next to the laser head, it can clear off the fumes and particles during laser cutting, to ensure the material and CCD camera and laser lens clean.

For another, the air assist can decrease the temperature of the processing area (that is called the heat-affected area), leading to a clean and flat cutting edge.

Our air pump can be adjusted to change the air pressure, which is suitable for different materials processing including acrylic, wood, patch, woven label, printed film, etc.

◾ Touch-Control Panel

This is the newest laser software and control panel. The touch-screen panel makes it easier to adjust the parameters. You can directly monitor amperage (mA) and water temperature right from the display screen.

Besides, the new control system further optimizes the cutting path, especially for the motion of dual heads and dual gantries. That improves the cutting efficiency.

You can adjust and save new parameters in terms of your materials to be processed, or use preset parameters built in the system. Convenient and friendly to operate.

Safety Device

Servo Motor

Auto Focus Device

RF Laser Tube

How to Select Suitable Laser Options for Your CCD Laser Cutter?

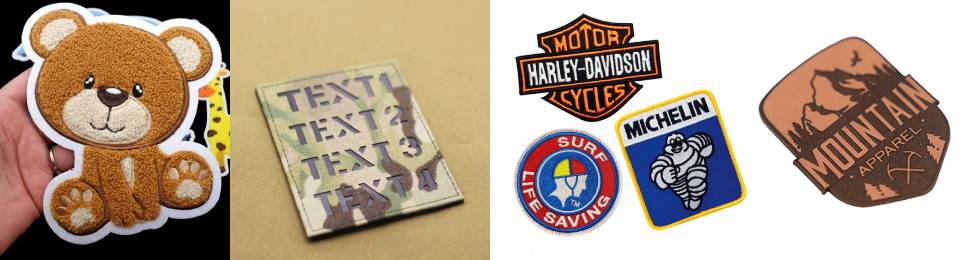

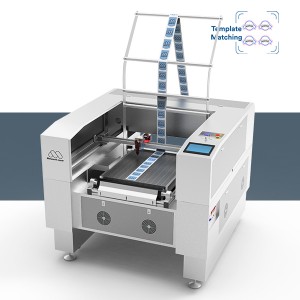

1. Laser Cutting Patches

Video Tutorial: CCD Camera Laser Cutting Embroidery Patch

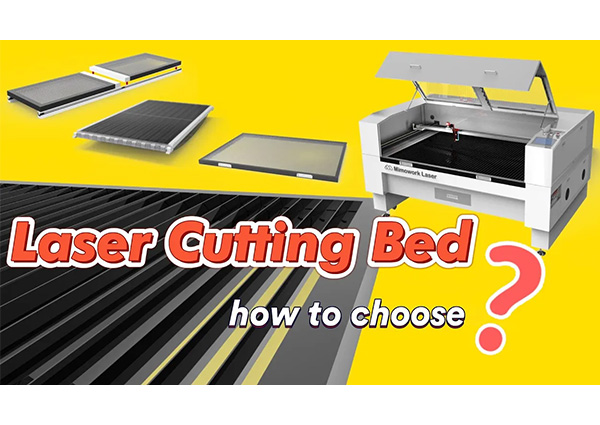

Step1. Put the material on the honeycomb laser cutting bed.

Step2. CCD camera recognizes the feature area of the embroidery patch.

Step3. Template matching the patches, and simulate the cutting route.

Step4. Set the laser parameters, and start laser cutting.

More Laser Cut Patches Samples

2. Laser Cutting Woven Label

Video Demo: How to Laser Cut Roll Woven Label?

You can use the CCD camera laser cutting machine to cut woven label. The CCD camera is able to recognize the pattern and cut along the contour to produce a perfect and clean cutting effect.

For roll woven label, our CCD camera laser cutter can be equipped with a specially designed auto-feeder and conveyor table according to your label roll size.

The recognition and cutting process is automatic and fast, greatly increase the production efficiency.

More Laser Cut Woven Labels

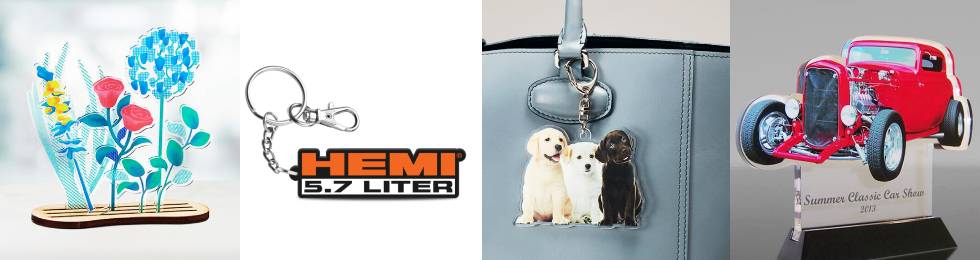

3. Laser Cutting Printed Acrylic & Wood

Video Display: CCD Camera Laser Cutting Printed Acrylic

The cut edges of laser cutting acrylic technology will display no smoke residue, implying that the white back will remain perfect. The applied ink was not harmed by the laser cutting. This indicates that the print quality was outstanding all the way to the cut edge.

The cut edge did not require polishing or post-processing because the laser-produced the requisite smooth cut edge in one pass. The conclusion is that cutting printed acrylic with a CCD laser cutter can produce the desired results.

More Samples of Laser Cut Printed Acrylic & Wood

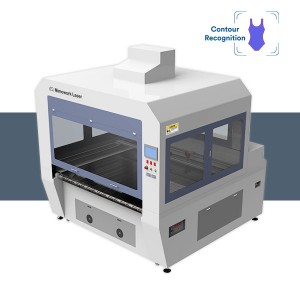

4. Laser Cutting Sublimation Textiles

Video Display: CCD Camera Laser Cutting Sublimation Pillowcase

The CCD Camera laser cutting machine not only cut small pieces like patches, acrylic decorations, but also cut large roll fabrics like sublimated pillowcase.

In this video, we used the contour laser cutter 160 with an auto-feeder and conveyor table. The working area of 1600mm * 1000mm can hold the pillowcase fabric and keep it flat and fixed on the table.