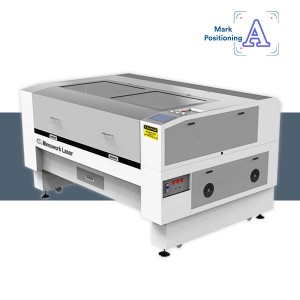

Contour Laser Cutter 60

Embroidery laser machine, woven label laser cutting machine

Technical Data

|

Working Area (W*L) |

600mm * 400mm (23.6” * 15.7”) |

|

Packing Size (W*L*H) |

1700mm * 1000mm * 850mm (66.9” * 39.3” * 33.4”) |

|

Software |

CCD Software |

|

Laser Power |

60W |

|

Laser Source |

CO2 Glass Laser Tube |

|

Mechanical Control System |

Step Motor Drive & Belt Control |

|

Working Table |

Honey Comb Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Cooling Device |

Water Chiller |

|

Electricity Supply |

220V/Single Phase/60HZ |

(Custom laser cut applique, label, sticker, printed patch)

The Highlights of Patch Laser Cutter

Optical Recognition System

◾ CCD Camera

The CCD Camera can recognize and position the pattern on the patch, label and sticker, instruct the laser head to achieve accurate cutting along the contour. Top-quality with flexible cutting for customized pattern and shape design like logo, and letters. There are several recognition modes: feature area positioning, mark point positioning, and template matching. MimoWork will offer a guide on how to choose appropriate recognition modes to fit your production.

◾ Real-Time Monitoring

Together with the CCD Camera, the corresponding camera recognition system provides a monitor displayer to inspect the real-time production condition on a computer. That is convenient for remote control and timely make an adjustment, smoothing production working flow as well as making sure safety.

Stable & Safe Laser Structure

◾ Compact Machine Body Design

Contour laser cut patch machine is like an office table, which does not require a large area. The label cutting machine can be placed anywhere in the factory, no matter in the proofing room or workshop. Small in size but provides you with great help.

◾ Air Blow

Air assist can clean off the fume and particles generated when the laser cut patch or engrave patch. And the blowing air can help to reduce the heat affected area leading to a clean and flat edge without extra material melt.

( * Timely blowing off the waste can protect the lens from damage to extend the service life.)

◾ Emergency Button

An emergency stop, also known as a kill switch (E-stop), is a safety mechanism used to shut down a machine in an emergency when it cannot be shut down in the usual way. The emergency stop ensures the safety of operators during the production process.

◾ Safe Circuit

Smooth operation makes a requirement for the function-well circuit, whose safety is the premise of safety production.

With the optional Shuttle Table, there will be two working tables that can work alternately. When one working table completes the cutting work, the other one will replace it. Collecting, placing material and cutting can be carried out at the same time to ensure production efficiency.

The size of the laser cutting table depends on the material format. MimoWork offers diverse working table areas to be selected according to your patch production demand and material sizes.

The fume extractor, together with the exhaust fan, can absorb the waste gas, pungent odor, and airborne residues. There are different types and formats to select according to actual patch production. On the one hand, the optional filtration system ensures a clean working environment, and on the other one is about environmental protection by purifying the waste.

Any questions about desktop laser cutter with camera

and how to choose laser options

Patch Laser Cutting Examples

▷ Typical Applications

Laser Kiss Cut Label, Patch

Laser Etched Leather Patches

Common Patch Laser Cutting

Patch laser cutting is popular in fashion, apparel, and military gear due to the top quality and optimal maintenance in functionality and performance. Hot cut from a patch laser cutter can seal the edge while patch cutting, leading to a clean and smooth edge that features a great appearance as well as durability. With the support of a camera positioning system, regardless of mass production, the laser cutting patch goes well due to the quick template matching on the patch and automatic layout for the cutting path. Higher efficiency and less labor make modern patch cutting more flexible and fast.

• embroidery patch

• vinyl patch

• printed film

• flag patch

• police patch

• tactical patch

• id patch

• reflective patch

• name plate patch

• Velcro patch

• Cordura patch

• sticker

• applique

• woven label

• emblem (badge)

▷ Video Demonstration

(With camera patch laser cutter)

How to cut out embroidery patches

1. CCD Camera extracts the feature area of the embroidery

2. Import the design file and laser system will position the pattern

3. Match the embroidery with the template file and simulate the cutting path

4. start accurate template cutting alone the pattern contour